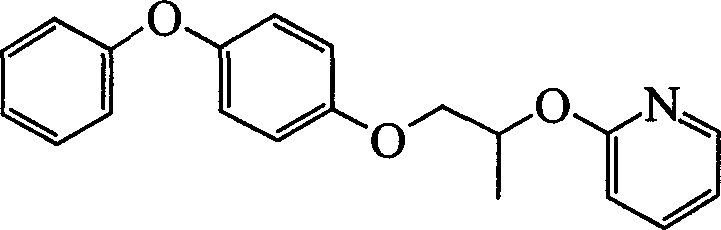

Separation and purification method of pyriproxyfen

A technology for separation and purification of pyriproxyfen, which is applied in the field of separation and purification of pyriproxyfen, which can solve the problems of low product purity, small amount of one-time separation, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

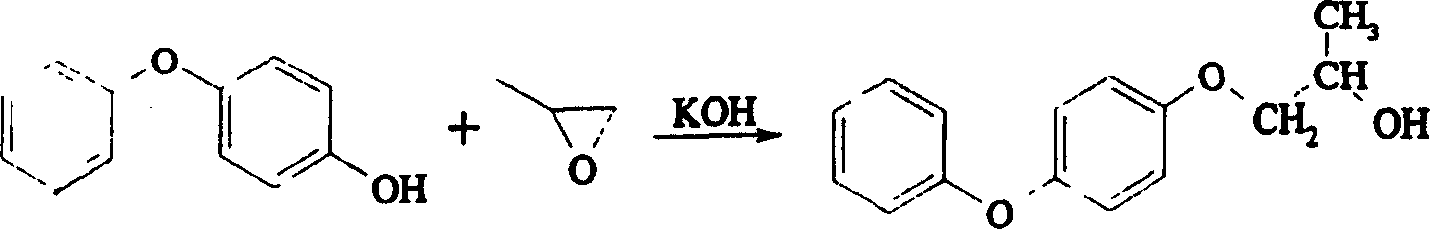

[0018] Put 30.0g (0.16mol) of p-phenoxyphenol, 2.7g (0.048mol) of potassium hydroxide and 100mL of water into a 250mL reaction flask, stir and heat to 40°C, add dropwise 18.4g (0.32mol) of propylene oxide, React at 40-60°C for 4h. The reaction mixture was cooled to room temperature and filtered to obtain 35-38 g of 1-(4-phenoxyphenoxy)-2-propanol.

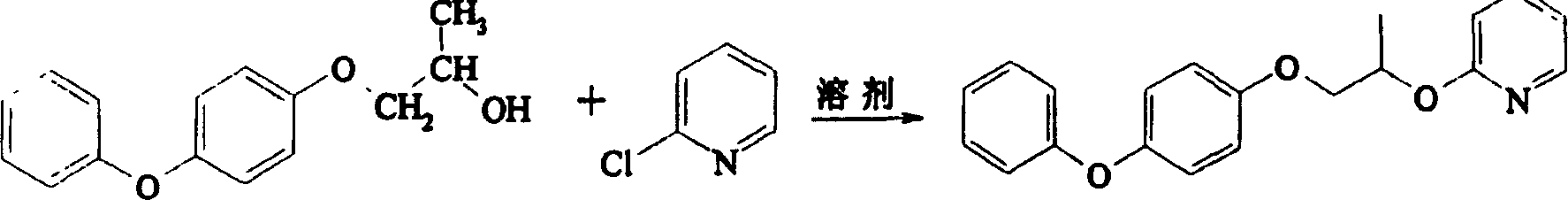

[0019] Put the above 1-(4-phenoxyphenoxy)-2-propanol, 25.0g (0.45mol) potassium hydroxide and 100mL ethylene glycol diethyl ether into a 250mL reaction flask, stir and heat to 80°C, drop Add 20.5g (0.18mol) of 2-chloropyridine and react at 80-120°C for 4h. The reaction mixture was cooled to room temperature, filtered, washed with water, and the filtrate was evaporated to remove the solvent under reduced pressure to obtain 47.0 g of crude pyriproxyfen. Quantitatively determined by HPLC, the content of pyriproxyfen was 85.1%.

[0020] Heat and dissolve the crude pyriproxyfen with 50mL of ethyl acetate, add 50-450mL of methanol, ad...

Embodiment 2

[0022] Put 30.0g (0.16mol) of p-phenoxyphenol, 2.7g (0.048mol) of potassium hydroxide and 100mL of water into a 250mL reaction flask, stir and heat to 40°C, add dropwise 18.4g (0.32mol) of propylene oxide, React at 40-60°C for 4h. The reaction mixture was cooled to room temperature and filtered to obtain 35-38 g of 1-(4-phenoxyphenoxy)-2-propanol.

[0023] Put the above 1-(4-phenoxyphenoxy)-2-propanol, 25.0g (0.45mol) potassium hydroxide and 100mL ethylene glycol diethyl ether into a 250mL reaction flask, stir and heat to 80°C, drop Add 20.5g (0.18mol) of 2-chloropyridine and react at 80-120°C for 4h. The reaction mixture was cooled to room temperature, filtered, washed with water, and the filtrate was evaporated to remove the solvent under reduced pressure to obtain 45.6 crude pyriproxyfen. Quantitatively determined by HPLC, the content of pyriproxyfen was 85.7%.

[0024] Heat and dissolve the crude pyriproxyfen with 50mL of toluene, add 50-450mL of methanol, adjust the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com