Separation and purification method for pertussis antigen

A technology for separation and purification of whooping cough, which is applied in the direction of bacterial antigen components, chemical instruments and methods, antibody medical components, etc. It can solve the problems that are not conducive to the production and income generation of vaccine companies, harsh elution conditions, and easy to degrade, and achieve rapid separation. Purification method, high purity of antigen, easy-to-obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 100

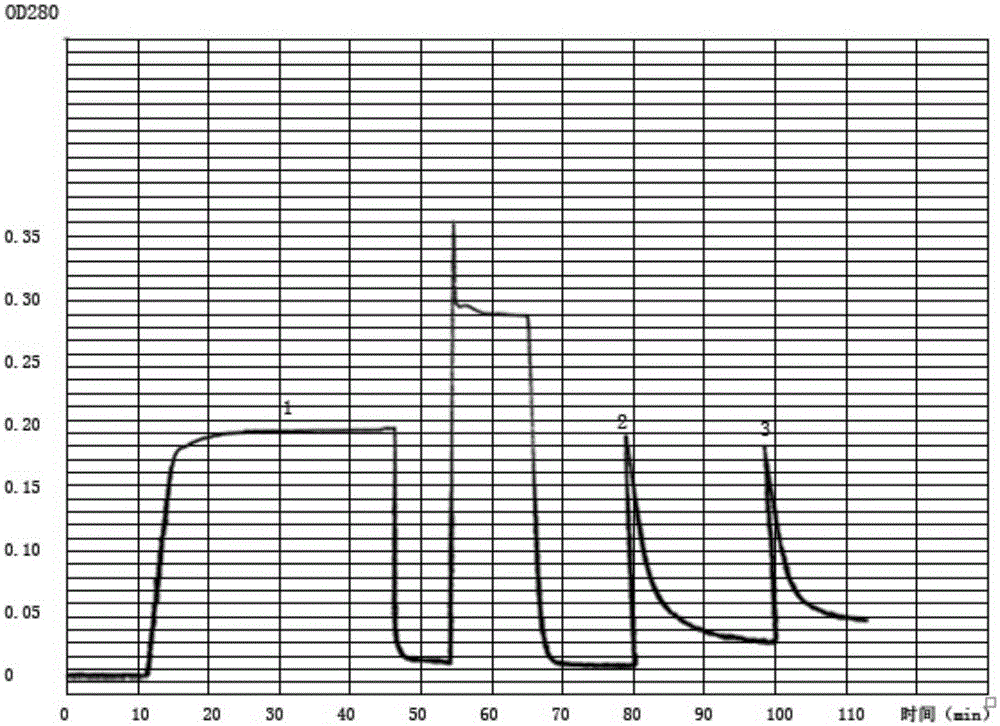

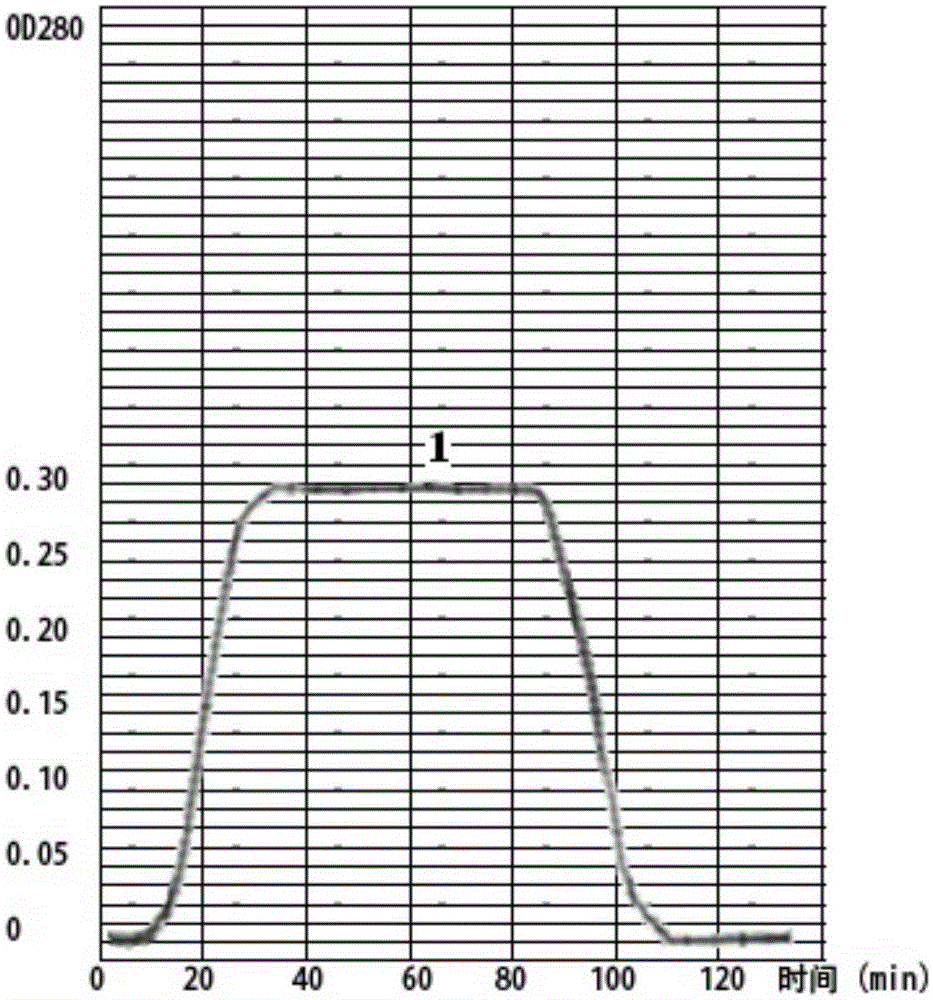

[0036] Example 1 Pertussis Antigen Isolation and Purification Method

[0037] Select domestic diatomite (Beijing Chuangqingyuan Filter Material Co., Ltd.), sieve to remove smaller and larger particles, and obtain a particle range of 60-200 μm. Use water for injection to wash the diatomite to remove floating and suspended matter , packed into a chromatographic column (Zhongsheng Huamei (Beijing) Technology Co., Ltd., column diameter 100mm), the packing height was 200mm, and the chromatographic column was washed with 5 times of 10mmol / LPB (pH8.0).

[0038] Open the freeze-dried strain bottle of Bordetella pertussis CS strain, purchased from China National Institutes for Food and Drug Control, transfer the strain to the modified ginger medium, culture at 35.5°C for 72 hours, collect and transfer to activated carbon half Cultivate on comprehensive medium at 35.5°C for 48 hours, then collect and transfer to activated carbon semi-comprehensive medium for 48 hours to collect strains....

Embodiment 2

[0043] Embodiment 2 diatomaceous earth specific adsorption PT and FHA

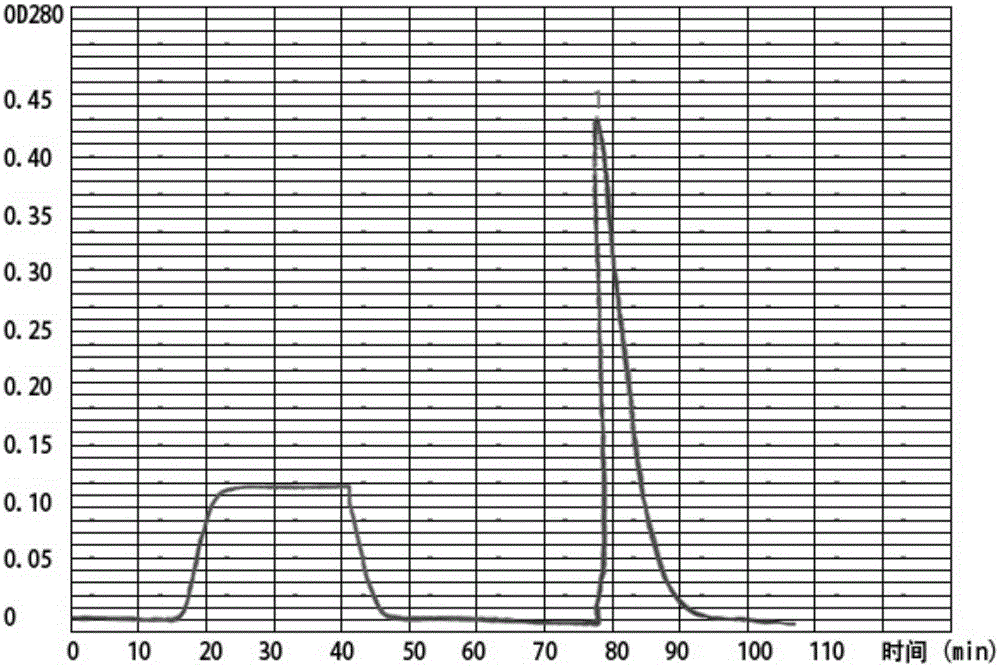

[0044] After 10 ml of the fermented broth concentrated in Example 1 was adjusted to 4-6 ms / cm with water for injection, it was thoroughly mixed with diatomaceous earth and allowed to stand at 4° C. for 10 minutes. Pour off the supernatant, wash the diatomaceous earth precipitate three times with 10ml10mmol / LPB (pH8.0), shake well each time, let it stand for 10 minutes, pour off the supernatant, after cleaning, add 10ml of 50mmol / LPB (pH 8.0) containing 0.5M NaCl was used for elution. The elution method was to shake the diatomaceous earth with buffer solution and then stand at 4°C for 10 minutes, and collect the supernatant. The supernatant was detected by electrophoresis, and the main components were PT and FHA. The results show that diatomite has specific adsorption on FHA and PT, and the elution of FHA and PT is related to the salt concentration.

Embodiment 3

[0045] Example 3 Purified PT and FHA purity detection

[0046] The purified PT and FHA were subjected to SDS-PAGE electrophoresis, and then the protein purity was determined by gel scanning.

[0047] The test method is to carry out SDS-PAGE electrophoresis with the 12% separation gel of the purified PT and PT standard substance with a concentration (the electrophoresis results are shown in Figure 4 ), the purified FHA and the FHA standard substance were carried out by SDS-PAGE electrophoresis with a concentration of 8% separating gel (see the electrophoresis results in Figure 5 ), after electrophoresis, the gel was scanned and analyzed to calculate the purity of the protein. Result shows that the PT of purification and PT standard substance, the FHA of purification and FHA standard substance have the same electrophoretic pattern, illustrate that PT and PT standard substance obtained by the method of embodiment 1, FHA and FHA standard substance have consistency, and purity a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com