Method for efficiently separating and purifying caffeoylquinic acid isomers from mulberry leaves

A technology for separation, purification and caffeoyl, which is applied in the field of efficient separation and purification of caffeoylquinic acid isomers, can solve problems such as not being used, and achieve the effects of reducing the number of extractions, reducing industrial costs and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Ultrasound-enhanced extraction: Accurately weigh 1 kg of mulberry leaf sample powder, use 4 L of ethanol with a volume concentration of 50% as a solvent, conduct ultrasonic treatment at room temperature for 45 minutes, extract 3 times, combine 3 extracts and filter, and concentrate the filtrate Until there is no alcohol smell, the concentrated extract is obtained;

[0069] (2) Ultrasonic vibration flocculation: Dissolve the concentrated extract in 2000mL of 40°C water for ultrasonic vibration flocculation. The ultrasonic vibration time is 5min and the frequency is 30KHz.

[0070] (3) pH-induced liquid-liquid extraction: use n-butanol to extract the supernatant, the volume ratio of n-butanol and supernatant is 1:1, the pH value of the extraction is 4, the extraction times is 5 times, and the n-butanol is concentrated The alcohol layer was dried to obtain the extracted product, and the extracted product was mixed with water and subjected to ultrasonic vibration floccu...

Embodiment 2

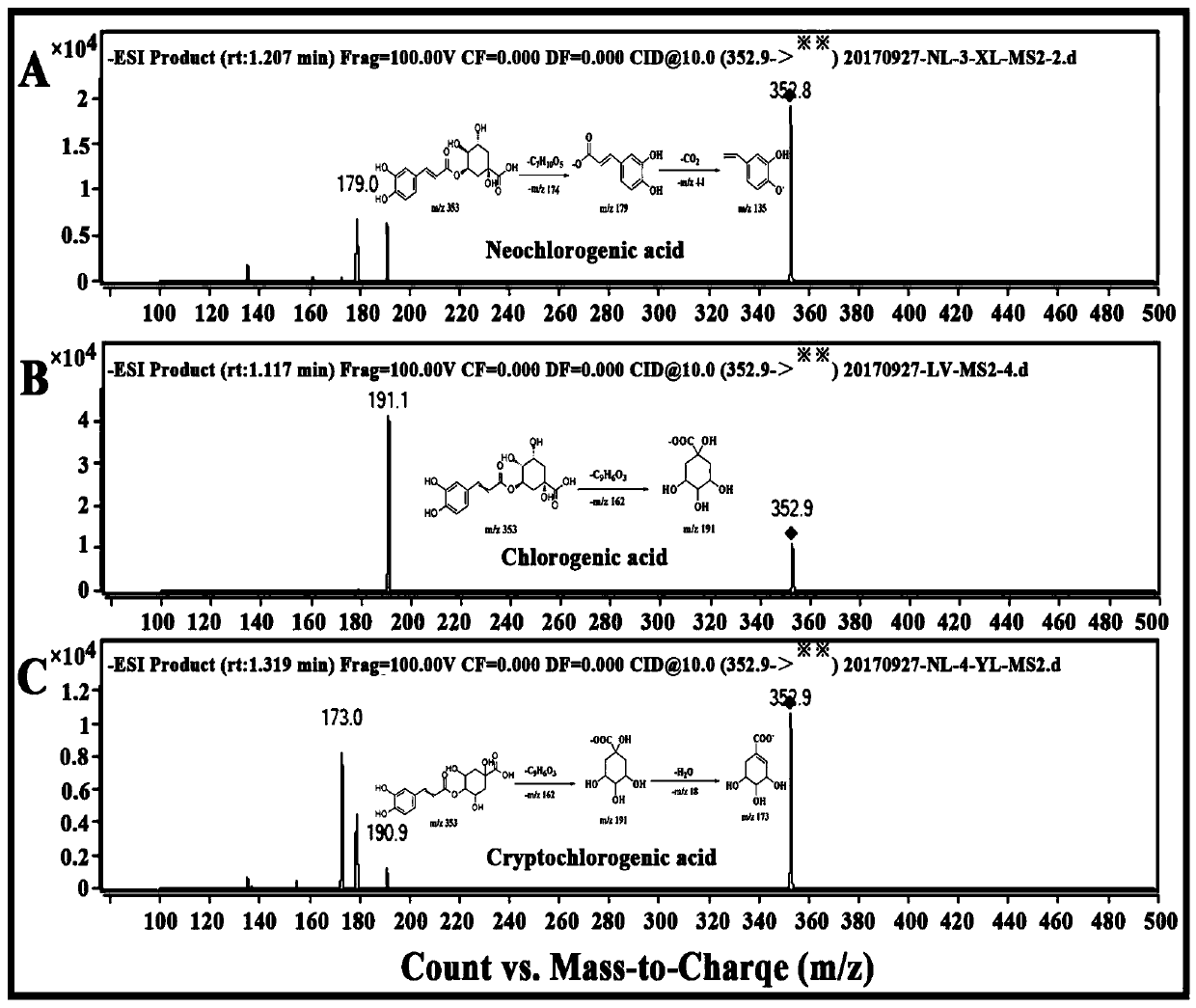

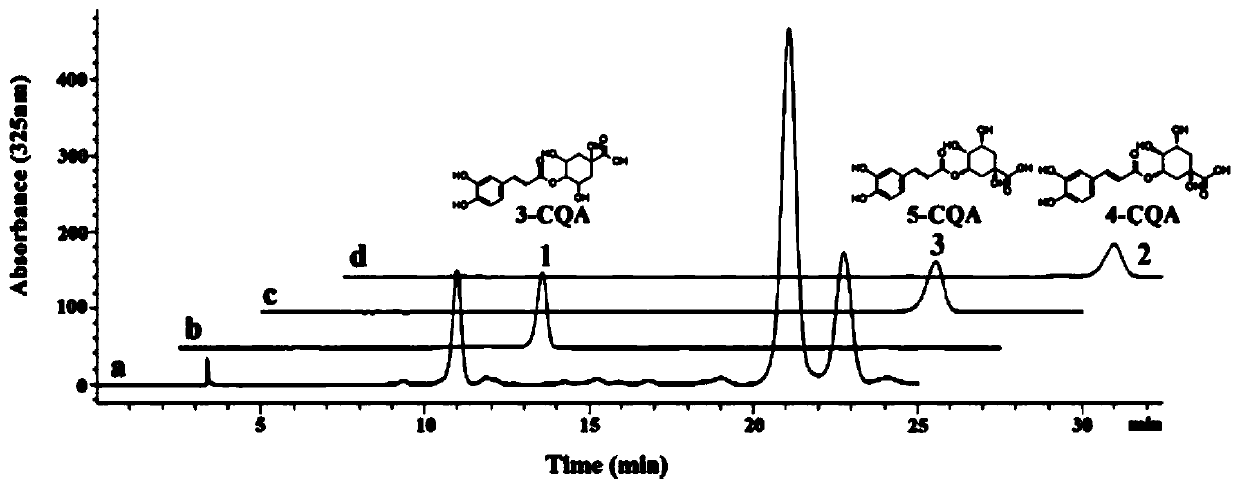

[0084] The separation effect of the high-speed countercurrent chromatography (HSCCC) method mainly depends on the selection of the two-phase solvent system, and the selection of the two-phase solvent system mainly considers the partition coefficient K and separation factor α of the separated substance in the solvent system. The best K value of HSCCC is generally 0.2-2.0. If the K value > 2.0, the separation time of the target component will be prolonged; when the K value < 0.2, the target component overlaps with other components and cannot be separated. In order to obtain better The separation factor α is preferably greater than 1.5.

[0085] In this example, the partition coefficient K of different caffeoylquinic acids in different two-phase solvent systems was measured by HPLC method, and the results are shown in Table 1.

[0086] Table 1 Distribution coefficient table of different caffeoylquinic acids in different two-phase solvent systems

[0087]

[0088]

[0089] ...

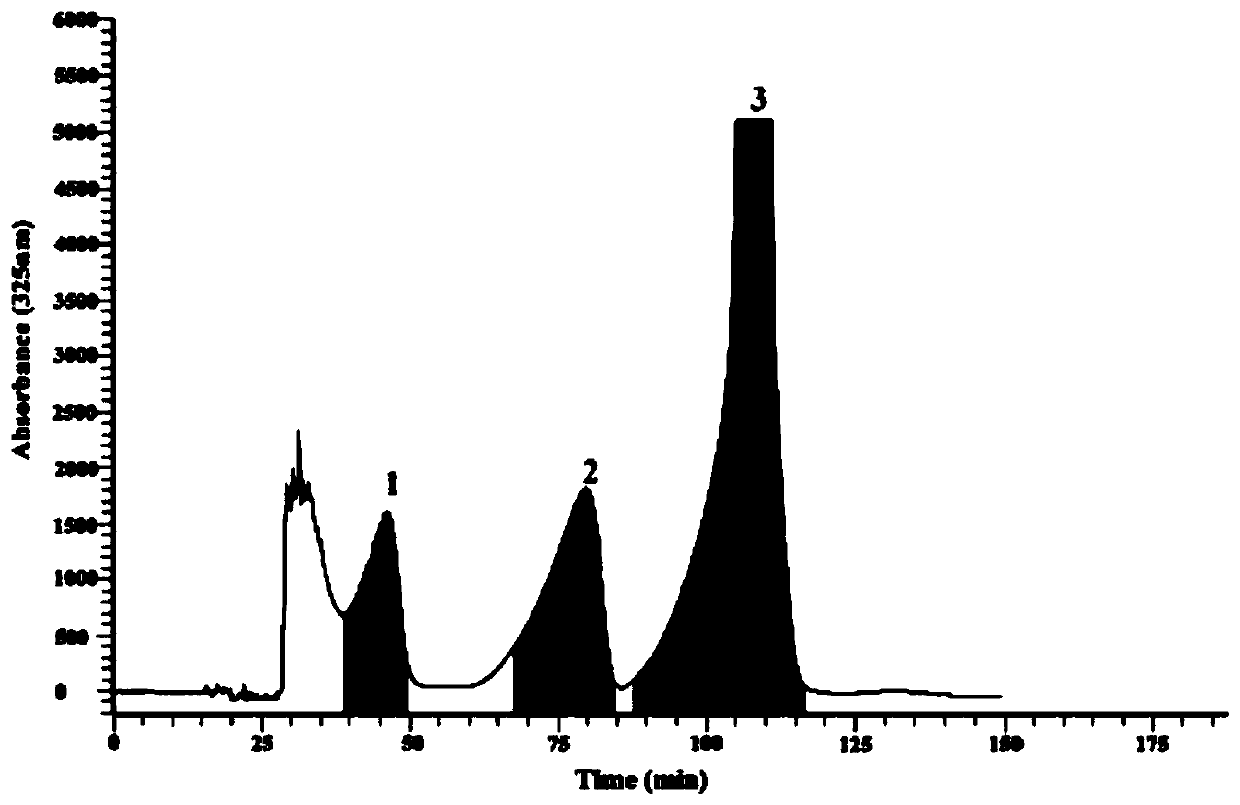

Embodiment 3

[0091] Other steps are the same as in Example 1, except that the pH value extracted in step (3) is changed to 5, the number of extractions is 5 times, the n-butanol layer is concentrated and dissolved in water to 2000mL, and the macroporous adsorption resin static adsorption sample solution is obtained. , the initial concentration of neochlorogenic acid in the sample solution was 0.47 mg / mL, the initial concentration of chlorogenic acid was 1.29 mg / mL, and the initial concentration of cryptochlorogenic acid was 0.65 mg / mL.

[0092] Carry out macroporous adsorption resin enrichment, high-speed countercurrent chromatography fast separation, low-temperature crystallization and recrystallization according to the method in embodiment 1, wherein the yield of new chlorogenic acid, chlorogenic acid and cryptochlorogenic acid after high-speed countercurrent chromatography fast separation Respectively can reach 80.59%, 99.56%, 94.21%, purity can reach 93.75%, 93.62%, 95.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com