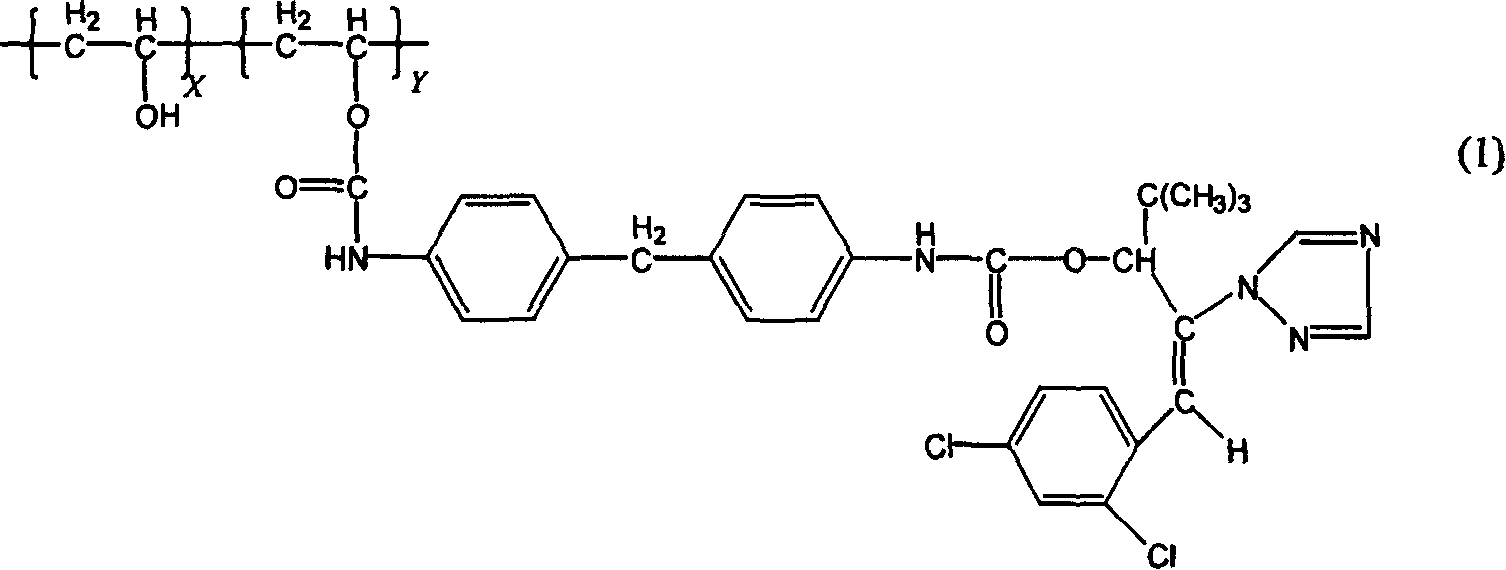

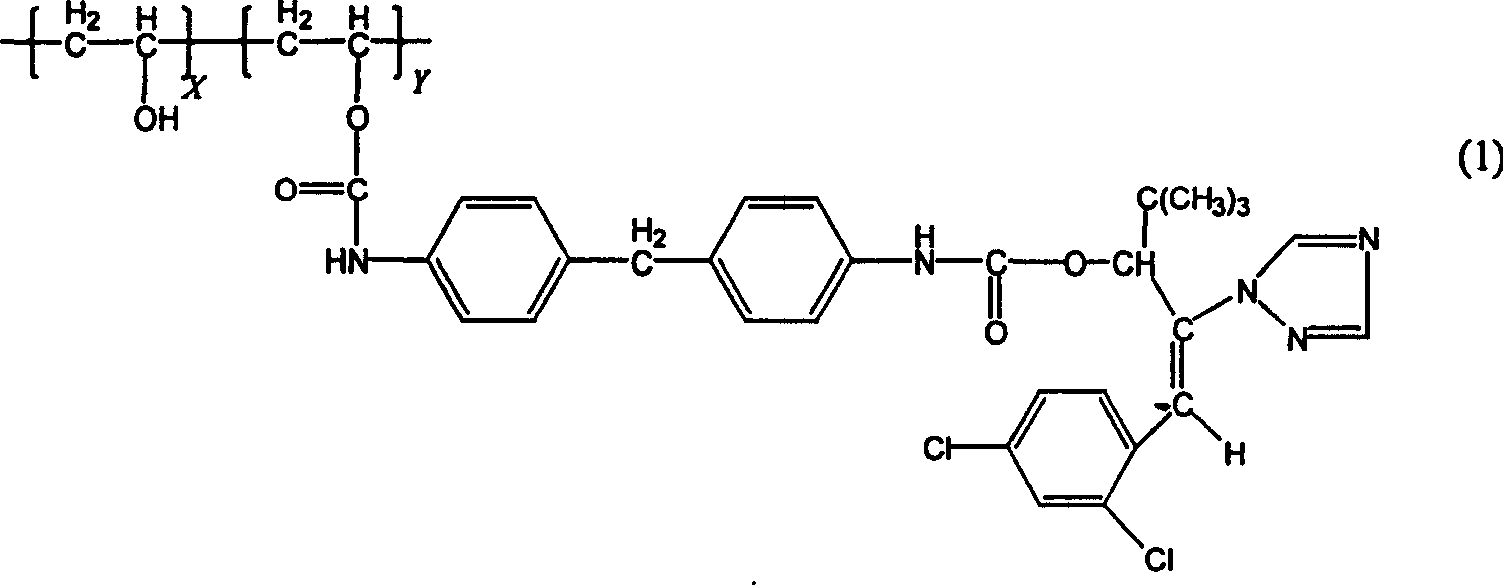

High molecular chemical slow releasing sterilizer containing diniconazole as biological active component

A bioactive component, polymer-based technology, applied in the field of agricultural chemicals, can solve the problems of large consumption of polymer substrates, no obvious advantages in production cost, low content of active molecules, etc., to achieve high content of active molecules, agricultural Cost reduction and long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

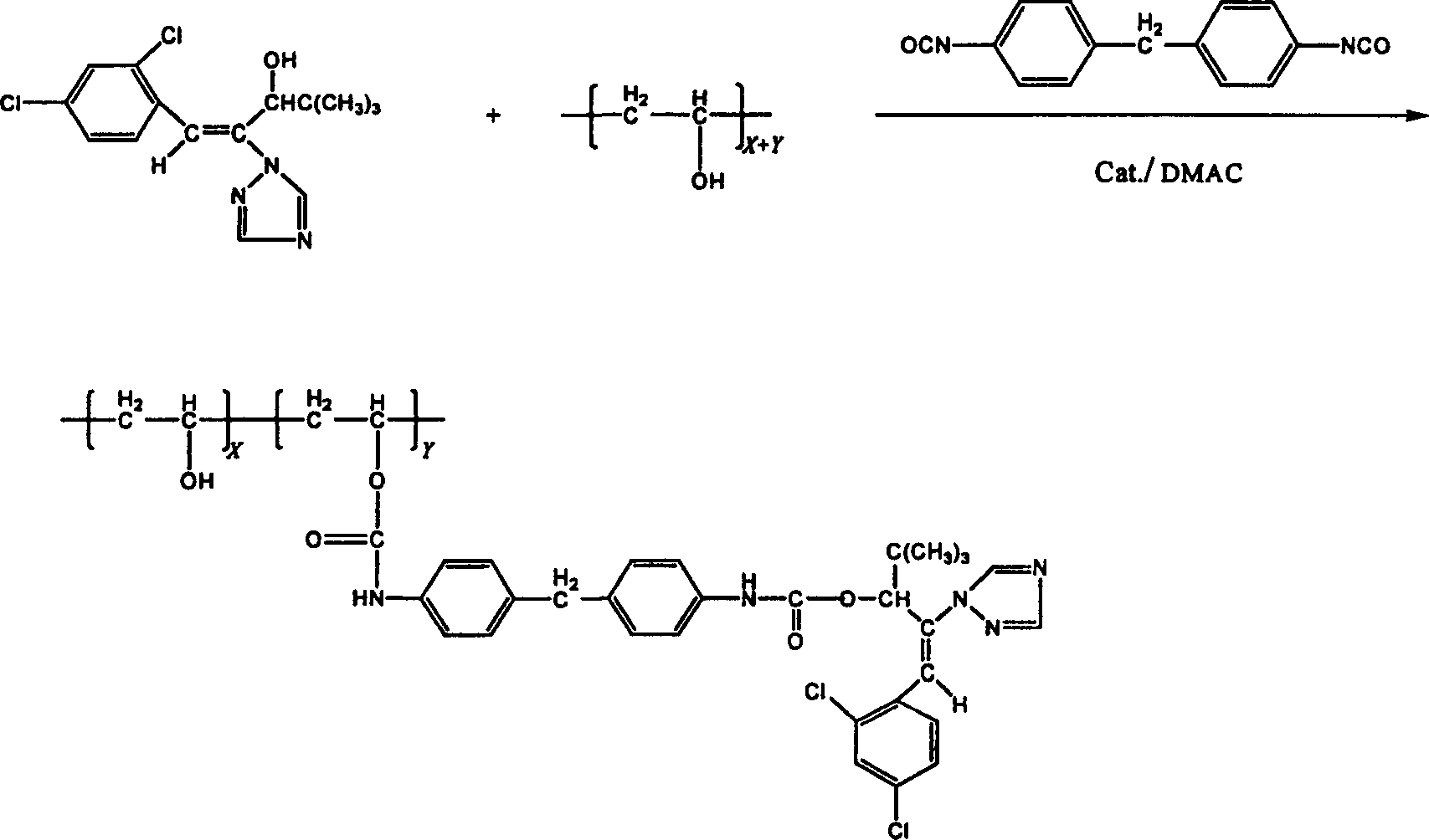

[0031] The preparation of example 1 polymer I

[0032]In a 125 ml four-necked flask equipped with a thermometer, a stirrer, a reflux condenser and a nitrogen device, add 60 ml of dry N,N-dimethylacetamide (DMAC) and 0.714 g (2.8 mmol) of 4 , 4'-diphenylmethane diisocyanate (MDI), nitrogen, stirring, heated to 100-110 ° C, dropwise added 0.920 g (2.8 mmol) of diniconazole and 10 ml of dry DMAC solution. After adding, keep stirring for about 1 hour, add 3.200 g of polyvinyl alcohol (polymerization degree: 1700:, alcoholysis degree: 99%) and 10 ml of dry DMAC solution, and react at 100±5°C for about 2 hours to the end. After cooling down to room temperature, a light brown gel was obtained as the crude product. The product was precipitated by methanol, filtered, and vacuum-dried to obtain 2.05 g of light yellow solid, which was the final product—Polymer I: 18% diniconazole content (weight content).

example 2

[0033] The preparation of example 2 polymer II~polymer V

[0034] Referring to the method of Example 1, polyvinyl alcohol with a degree of polymerization of 100, 1450, 2600 and 7,500,000 to 10,000,000 was used as a carrier polymer to synthesize polymers II to V, as shown in Table 1:

[0035] polymer

Bridging agent

Alcoholysis degree of polyvinyl alcohol%

II

MDI

84

100

III

MDI

88

1,450

IV

MDI

99

2,600

V

MDI

99

7,500,000~

10,000,000

[0036] Infrared Spectrum of Polymer I~Polymer V:

[0037] IR v max : 3600~3200cm -1 (alcohol-OH characteristic absorption), 3400~3000cm-1 (N-H stretching vibration of amide), 2980~2840cm -1 (saturated hydrocarbon C-H stretching vibration), 1730cm -1 (s, C=O), 1650cm -1 、1620cm -1 、1580cm -1 、1510cm -1 (Olefin C=C, benzene ring skeleton vibration), 1560cm -1 (m, C=N), 1260cm...

example 3

[0038] Example 3 Hydrolysis Release of Polymer I~Polymer V Active Components

[0039] Hydrolysis release test According to the literature (El-Refaie Kenawy, et al., J Appl Polym Sci, 2001, 80: 415-421), 100 mg of pulverized polymer (DMP) was placed in 100 ml of buffer solution In the volumetric flask, keep the water bath at a constant temperature of 25°C without stirring. Buffer solutions with pH=4, 7, and 9 were respectively prepared with acetic acid-sodium acetate, mixed phosphate and ammonium chloride-ammonia water. Periodically extract the test solution and use the HPLC method (Waters high-performance liquid chromatography, Waters 510pump, detector Waters486, 254nm is the detection wavelength) to analyze the content of the active component released by hydrolysis-diniconazole. The hydrolysis experiment result of polymer (DMP) shows: in the buffer solution of different pH value, the initial release concentration of active component is all very high, and release amount can r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com