Use of liquid carbohydrate fermentation product in foods

A fermented product, a technology of liquid fermentation, applied to sugar fermented products, the invention relates to the field that can be used in food or medicine and only requires the least processing steps, and can solve the problems that have not been raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The preparation of embodiment 1-fermentation broth

[0049] This synthesis uses well-known methods for preparing xanthan gum fermentation broths (such as those described in the prior art eg US Patents US 3,000,790; US 3,020,207; US 3,557,016 or US 4,299,825). More specifically, a xanthan gum fermentation broth is prepared by fermentation of the microorganism Xanthomonas campestris on a substrate of hydrolyzed potato starch or equivalent sugars under biosynthetic conditions. After fermentation, the broth is heated and about 10% by weight of the resulting broth is added with glacial acetic acid to make the pH of the broth lower than 3.0. The weight percent content of xanthan gum in the obtained broth was 3.24%.

example 3- Embodiment 1 and comparative example 2

[0052] Hydration performance of the composition of example 3-embodiment 1 and comparative example 2

[0053] To measure the hydration properties of the compositions of Example 1 and Comparative Example 2, two aqueous solutions were prepared. An amount was added so that each aqueous solution contained 0.5% by weight xanthan gum. The solutions are as follows, with parts expressed by weight.

[0054] Solution A

[0055] Component

[0056] Component

Embodiment 4

[0057] Example 4 - Composition of salad dressing using the composition of Example 1

[0058] Using the liquid xanthan gum broth of Example 1, a low fat (8% fat) Italian salad dressing was prepared as follows. 6.00 parts of sucrose were added to 55.90 parts of water and the resulting solution was mixed at 500 rpm for 2 minutes. A slurry of 27.40 parts of the composition of Example 1 in 8.20 parts of soybean oil was added to the water / sucrose solution and mixed at 2000 rpm for 3 minutes. 2.50 parts of sodium chloride were added to the solution and the resulting mixture was mixed at 2000 rpm for 3 minutes.

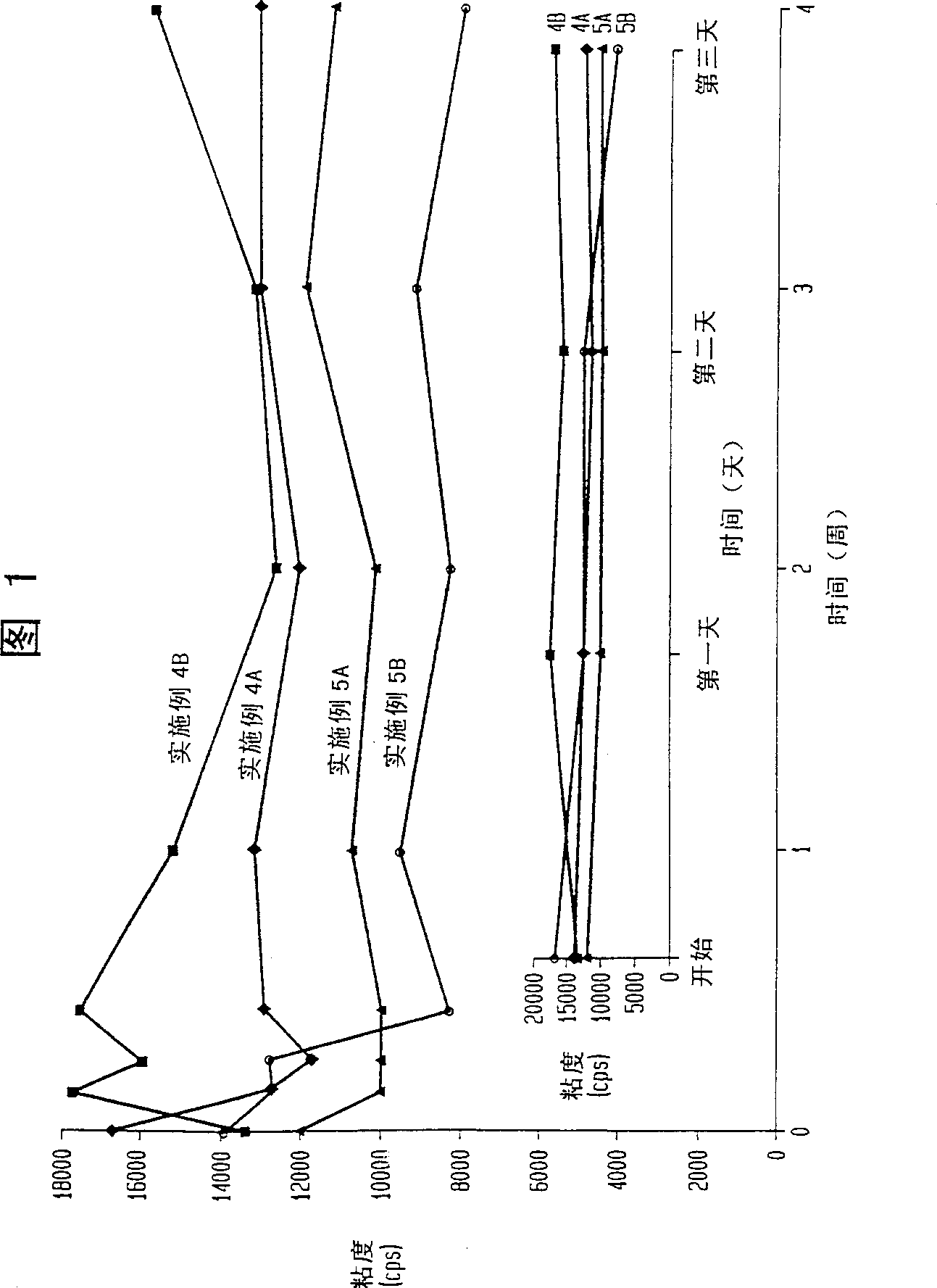

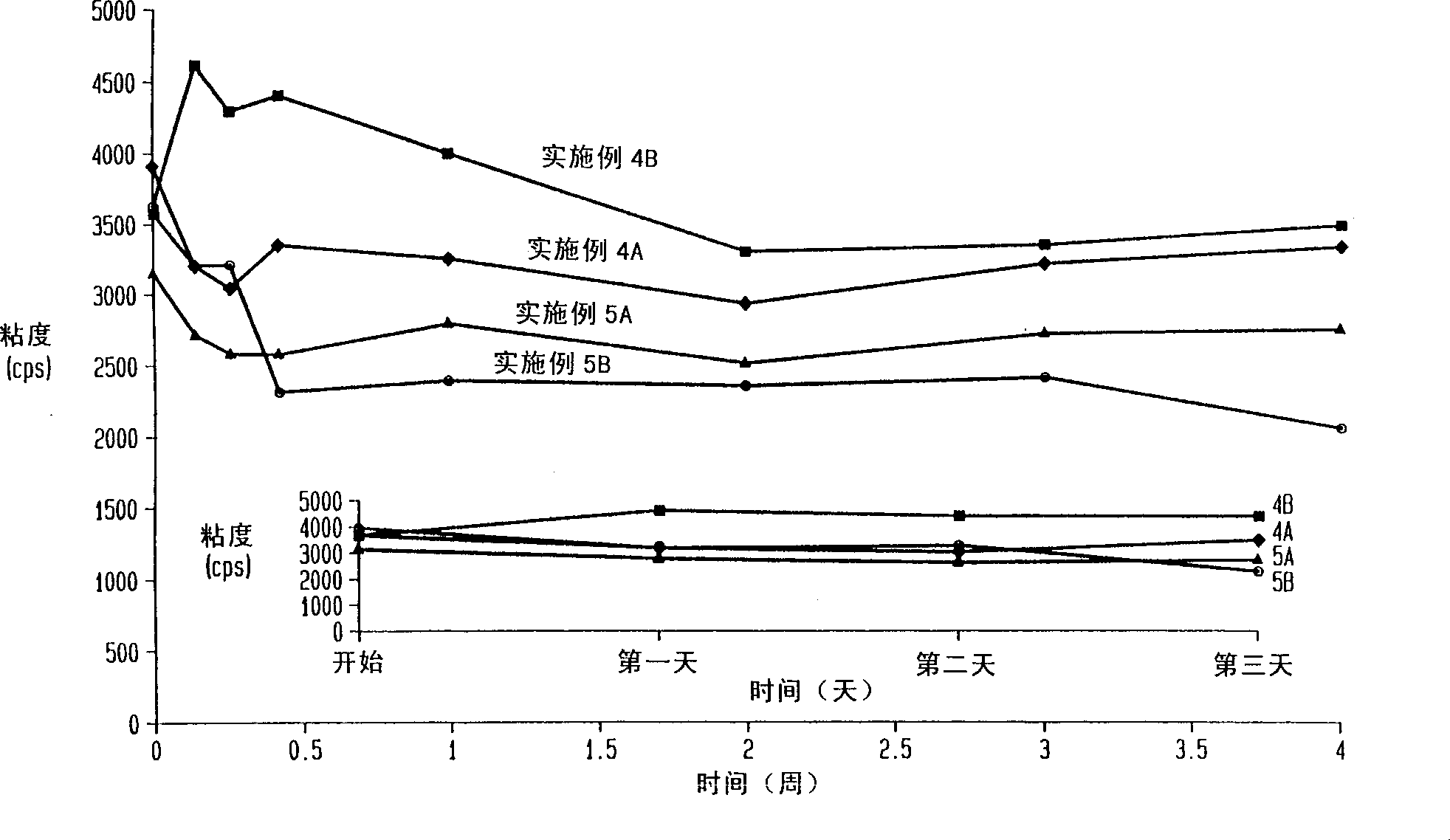

[0059] The resulting mixture was divided into 2 parts for comparative tests. Part 1, referred to as Example 4A, was set aside to measure viscosity and the other part was continuously homogenized with a microfluidics homogenizer (HC-5000) at 2500 pounds per square inch, then cooled to 25°C and referred to as Example 4B. The viscosity of Example 4B was measured. Homogeniza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com