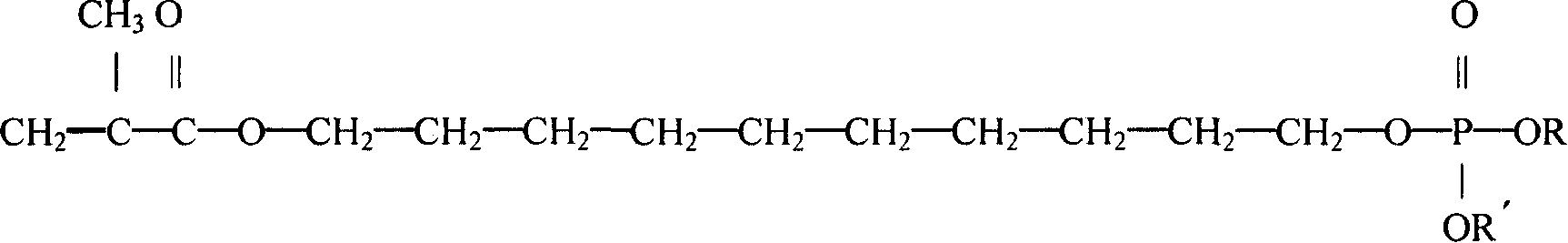

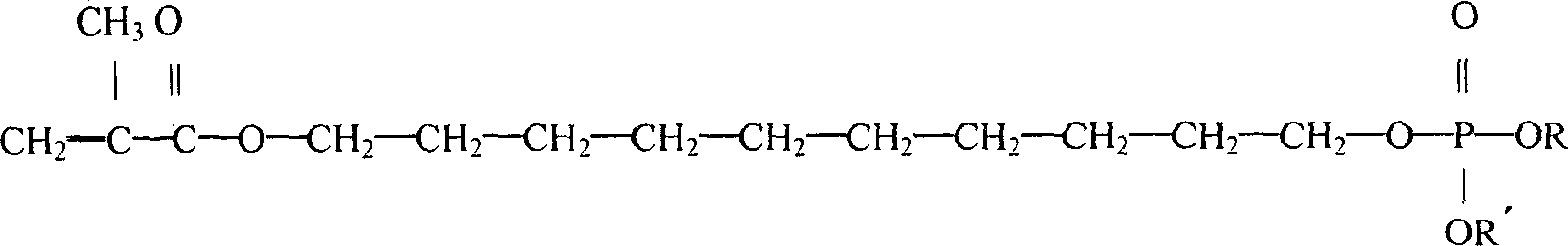

Monoester phosphate containing meth-acrylate structure, its preparing method and use

A technology of methacrylate and methacrylic acid, applied in the direction of phosphorus organic compounds, chemical instruments and methods, dissolution, etc., can solve the problems of affecting the performance of the coating film, consuming large emulsifiers, etc., and achieve good performance and easy control of conditions , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

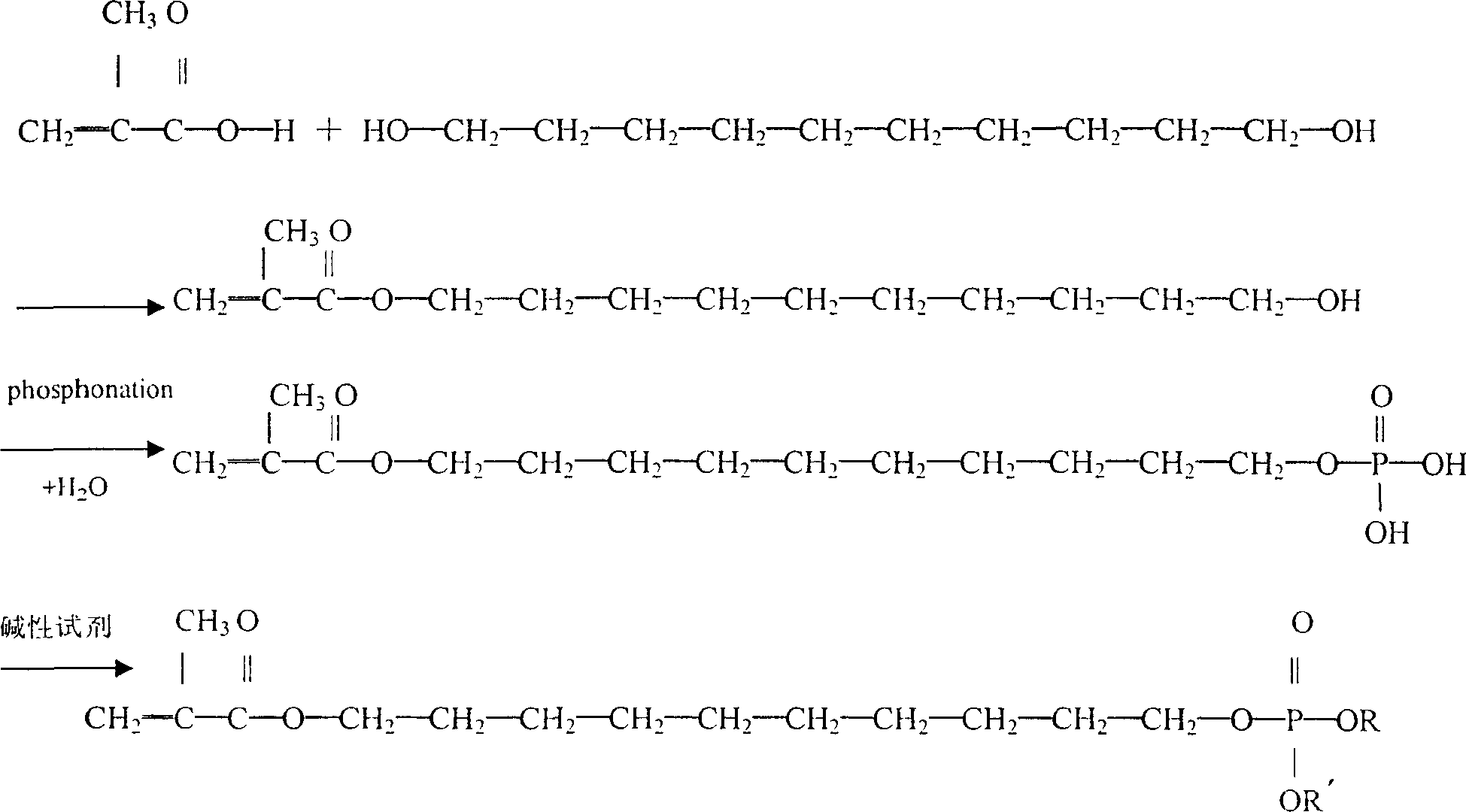

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of methacrylic acid-ω-hydroxydecyl ester: use 1.00 molar parts of methacrylic acid and 1.2 molar parts of 1,10-decanediol as raw materials to prepare monoester; catalyst p-toluenesulfonic acid accounts for methacrylic acid and 1 , 10% of the total mass of 10-decanediol, the polymerization inhibitor hydroquinone accounts for 0.1% of the total mass of methacrylic acid and 1,10-decanediol, the reaction condition is 75°C, and the reaction time is 6h;

[0026] (2) Preparation of phosphorylation reagent: take 0.0293 mole parts of phosphoric acid with a mass fraction of 85%, add 0.0288 mole parts of phosphorus pentoxide in batches under stirring, stir and heat up to 88°C for 1 hour after the addition, and prepare poly Phosphoric acid serves as a phosphorylation reagent. Let cool and set aside.

[0027] (3) Phosphorylation reaction: get 0.02 mole portion of monoester obtained in step (1) and the newly prepared whole phosphorylation reagent in step (2) to react ...

Embodiment 2

[0030] (1) Preparation of methacrylic acid-ω-hydroxydecyl ester: prepare monoester with 1.00 molar parts of methacrylic acid and 1.25 molar parts of 1,10-decanediol; catalyst p-toluenesulfonic acid accounts for methacrylic acid and 1 , 12% of the total mass of 10-decanediol, the polymerization inhibitor hydroquinone accounts for 0.15% of the total mass of methacrylic acid and 1,10-decanediol, the reaction conditions are 78 ° C, and the reaction time is 5h;

[0031] (2) Preparation of phosphorylation reagent: Take 0.0293 mole parts of phosphoric acid with a mass fraction of 85%, add 0.0282 mole parts of phosphorus pentoxide in batches under stirring, stir and heat up to 89°C for 1.5h after the addition, and obtain more Polyphosphoric acid was used as a phosphorylation reagent. Let cool and set aside.

[0032] (3) Phosphorylation reaction: get monoester 0.02 mole portion obtained in step (1) and the newly prepared phosphorylation reagent reaction in step (2) to prepare phosphor...

Embodiment 3

[0035] (1) Preparation of methacrylic acid-ω-hydroxydecyl ester: prepare monoester with 1.00 molar parts of methacrylic acid and 1.3 molar parts of 1,10-decanediol as raw material; catalyst p-toluenesulfonic acid accounts for methacrylic acid and 1 , 11% of the total mass of 10-decanediol, the polymerization inhibitor hydroquinone accounts for 0.15% of the total mass of methacrylic acid and 1,10-decanediol, the reaction conditions are 80°C, and the reaction time is 5h;

[0036] (2) Preparation of phosphorylation reagent: Take 0.0293 mole parts of phosphoric acid with a mass fraction of 85%, add 0.0285 mole parts of phosphorus pentoxide in batches under stirring, stir and heat up to 90°C for 1.2h after the addition, and obtain more Polyphosphoric acid was used as a phosphorylation reagent. Let cool and set aside.

[0037] (3) Phosphorylation reaction: get 0.02 mole parts of the monoester obtained in step (1) and react with the newly prepared phosphorylation reagent in step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com