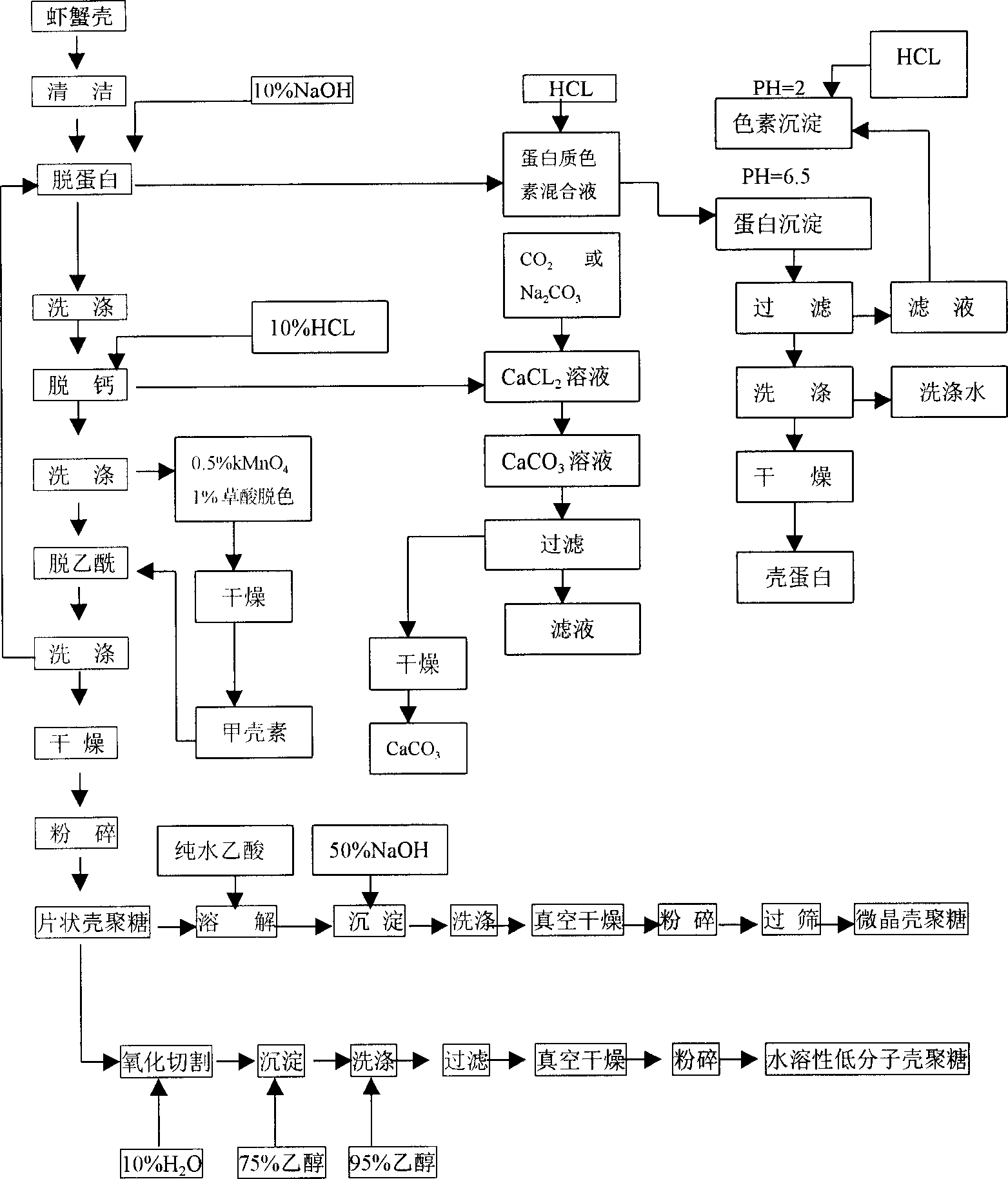

Technology for producing high chitosan, microcrystall chitosan and water-soluble low molecular chitosan

A technology of high deacetylation and production process, applied in the field of flaky chitosan with high degree of deacetylation, can solve the problems of long decalcification time, high product impurity content, high price, etc., and achieves avoiding product oxidation and high deacetylation degree. , the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

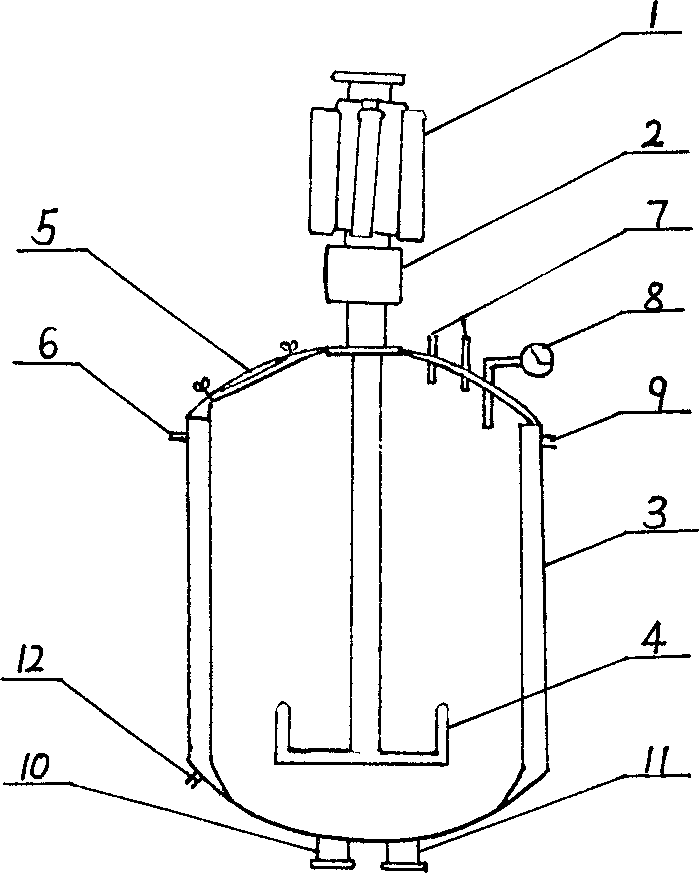

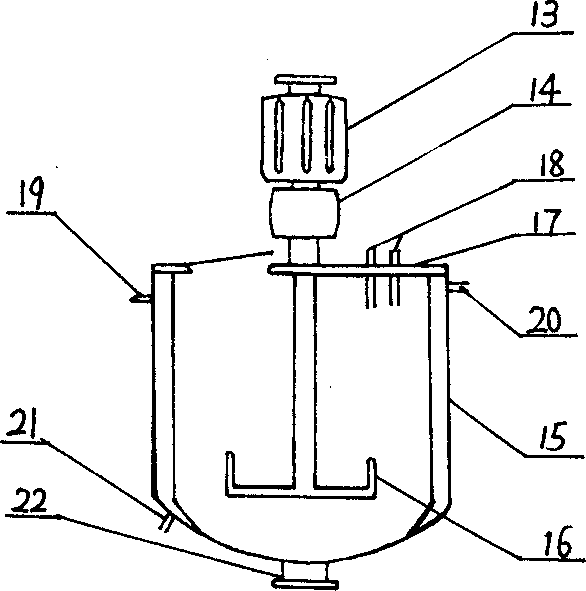

[0012] 1. Open the feed port of the primary reactor, remove the impurities of shrimp, crab shells and other raw materials into the primary reactor after sorting, washing, and adding 10% NaOH solution from the liquid adding pipe 7 to the boiling point, and keeping it for 60 minutes. In the meantime, the motor 1 is started, and the reducer 2 drives the stirring rod 4 to continuously stir. After the deproteinization is complete, open the valve of the washing liquid outlet 11 to drain the waste liquid into the waste liquid pool, and rinse the deproteinized product with tap water and use hydrochloric acid at the same time Adjust the waste liquid to a PH value of 5-6. At this time, the protein precipitates out. After filtration, the salt is washed away with fresh water to obtain high-quality protein. After hydrolysis, it can be made into an amino acid nutrient solution. The filtrate is adjusted to a pH value of 2 with hydrochloric acid. At this time, the astaxanthin precipitated can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com