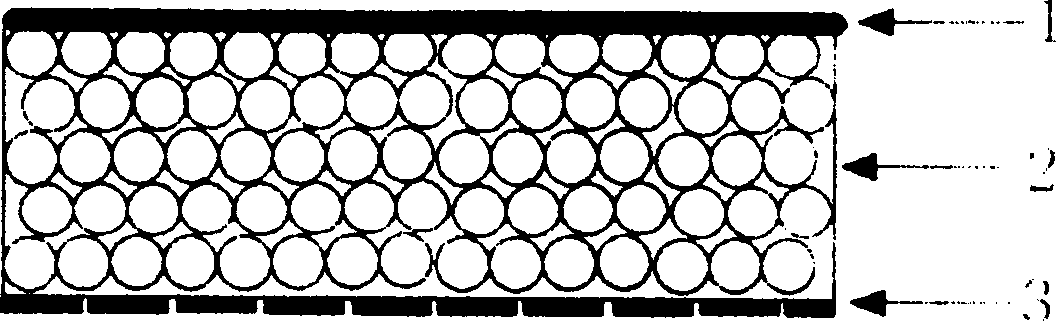

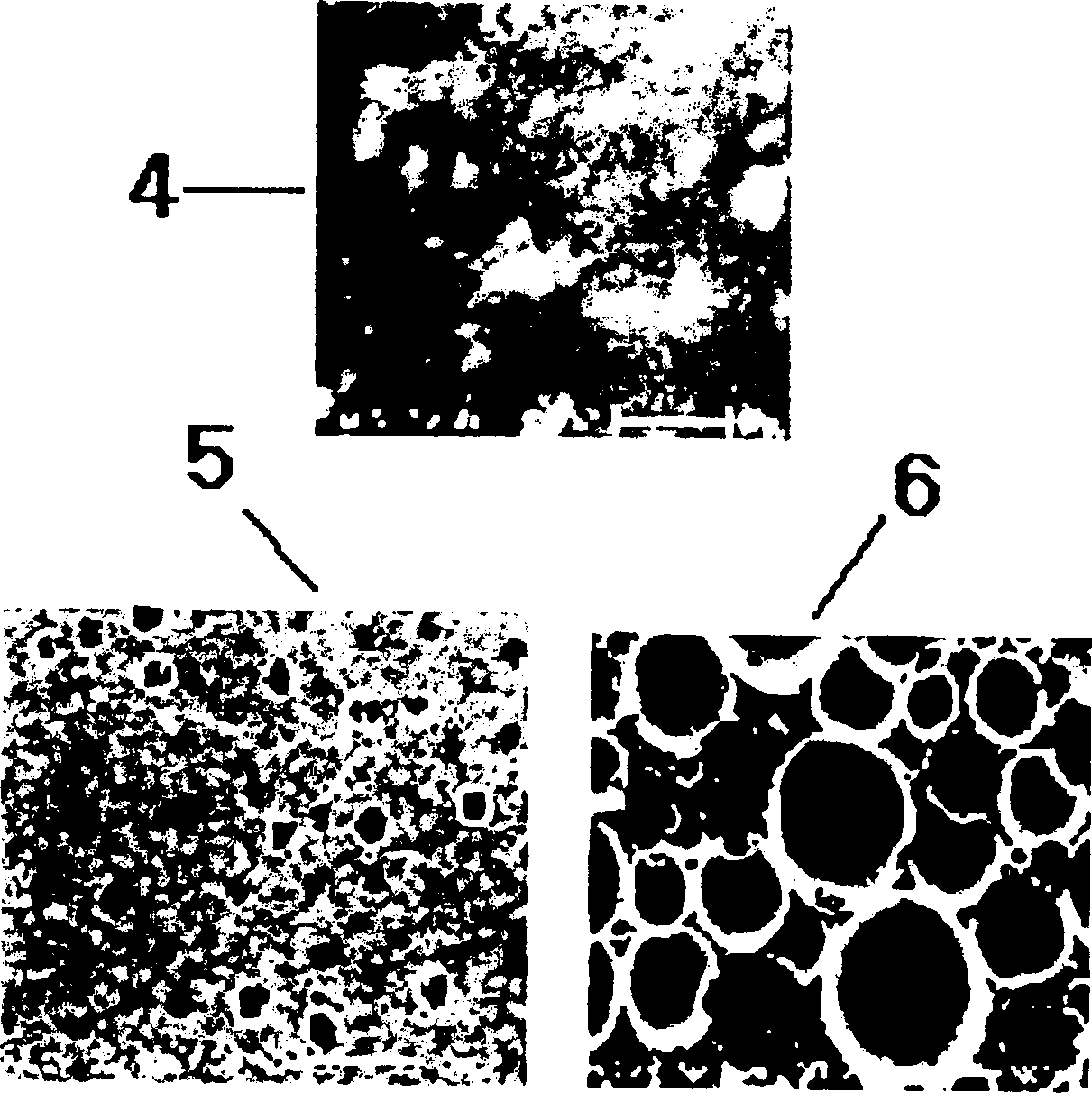

Multilayer polyporous foam dressing material and its producing method

A microporous, foam technology, applied in viscous dressings, dressings, etc., can solve problems such as difficulty in wide use, inappropriate wounds, and complicated manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 2

[0031] When producing polyurethane prepolymers with isocyanate end groups, use a 3-liter round-bottomed flask equipped with a stirrer to put 242.8g of toluene isocyanate (TDI), and after the humidity rises to 60°C, add a small amount of 3 hydroxyl groups, and ethylene oxide / propylene oxide random copolymer, TR-705 (Polyol company) 816.3g with ethylene oxide content of 75%, and polypropylene glycol GT-4000 ( Polyol company) 435.4g, manufacture through the chemical reaction of 7 hours, be 5.7 until reaching theoretical NCO content. Samples were taken during the reaction to measure the NCO content. At this time, use n-butylamine standard solution and measure according to the titration method. [Example 1]

Embodiment 1

[0032] The production process of the outer protective film is as follows. Put 18g of polyurethane elastomer into DMF / MEK (40 / 60) solvent, heat and stir at 60°C, and dissolve into a colorless and transparent polyurethane solution in a viscous liquid state. After sticking adhesive tape on its periphery, drip polyurethane solution on release paper made of silicon with a certain thickness, and then spread it evenly with a film coating machine to form a certain thickness, then dry it in an oven at 100°C for one hour. many hours. The film thicknesses after drying were 15, 30, and 50 μm, respectively. [Example 2]

Embodiment 2

[0033] The manufacturing process of the hydrophilic polyurethane foam dressing is as follows. 27.2% by weight of distilled water as a foaming agent, 13.6% by weight of glycerin as a crosslinking agent, and 0.5% by weight of F-127 (BASF Corporation) as an additive were added to 57.1% by weight of the polyurethane prepolymer produced in Synthesis Example 1 above. %, 0.9% by weight of L-64, 0.5% by weight of sodium alginate, after stirring for 5 seconds at 4000rpm, stick the polyurethane film with a thickness of 15 μm made in Example 1 on the molding side, and then inject it into a certain In the mold of the shape, the final foam is made. At this time, the temperature of the mold is 35°C, and it is opened after 10 minutes of injecting the liquid, and the density of the prepared dressing is 0.21g / cm 3 .

[0034] The hydrophilic polyurethane foam dressing thus obtained was measured for its physical properties according to the following methods, and the above measurement results a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com