Surface modifying method for porous Ni-base cathode material in fusion carbonate fuel battery

A molten carbonate and fuel cell technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of cracking ceramic materials, aggravating materials, and long time, so as to improve strength and toughness, uniform film thickness, The effect of increasing the number of grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 1.725gLiNO 3 and 7.725gCo(NO 3 ) 2 ·6H 2 O mixed and dissolved in deionized water, the resulting solution was mixed with 1.2ml polyacrylic acid (PAA) and the volume was adjusted to 200ml, and HNO was added dropwise under stirring 3 , adjust the pH value to 1.5 and continue to stir for 40min. The synthesis solution was hydrolyzed at 75° C. and evaporated for 24 hours to obtain a pink sol (sol). The temperature was kept constant, and the solution was stirred to continue to remove water to obtain a pink gel (gel) precursor. After the gel was dried, it was pre-calcined at 300°C for 1 h to remove organic matter, and then calcined at 650°C for 1.5 h to obtain LiCoO 2 Nano powder. XRD and TEM test results show that LiCoO 2 The powder composition is simple, the crystallinity is good, and the particle size is 50-70nm.

[0020] Take 0.1g LiCoO 2 Nanopowder, dispersed by ultrasound in 25ml isopropanol to make a suspension, with HNO 3 Adjust the pH to 4.38. At room t...

Embodiment 2

[0025] LiCoO 2 The preparation of nanopowder is the same as embodiment 1, take LiCoO 2 Disperse 0.1g of nano powder in 25ml of acetylacetone to make a suspension, adjust the pH value to 2.50, at room temperature, use a porous Ni material with a thickness of 1.066mm and a porosity of 73.7% as the cathode, and the platinum electrode as the anode. 2 Electrophoretic deposition in suspension, the electrophoretic deposition conditions are voltage 150V, current 8mA, and the deposition time is 1min on both sides of the material. 2 Calcined in atmosphere for 3h to get Ni-LiCoO 2 composite material. at 470°C and CO 2 :O 2 :N 2 In a mixed atmosphere of 0.20:0.15:0.65, against Ni-LiCoO in molten carbonate 2 The composite material was pre-oxidized in situ for 10 h.

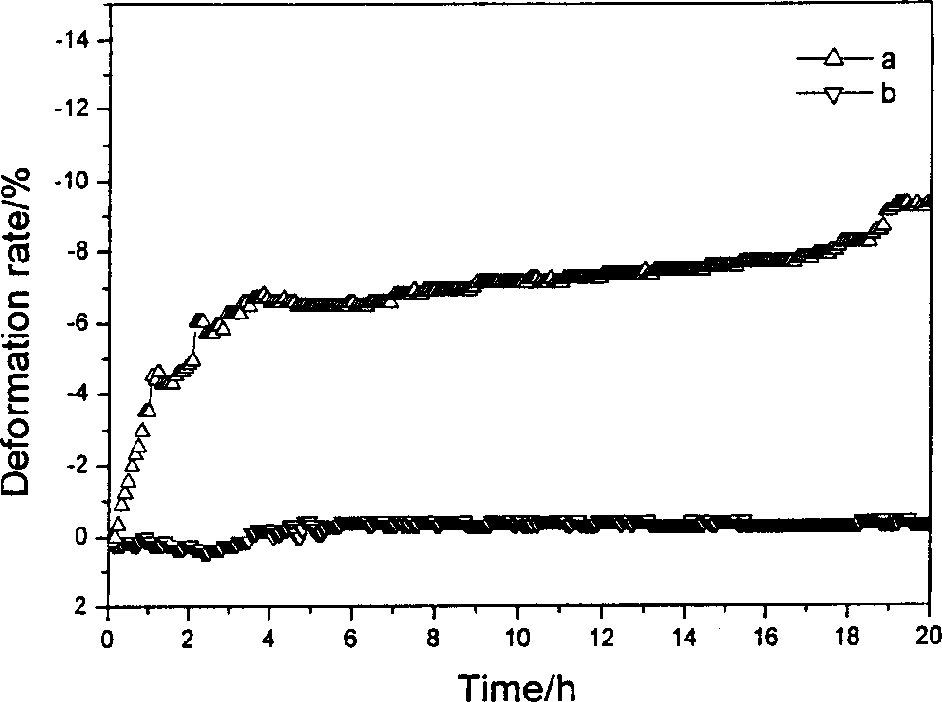

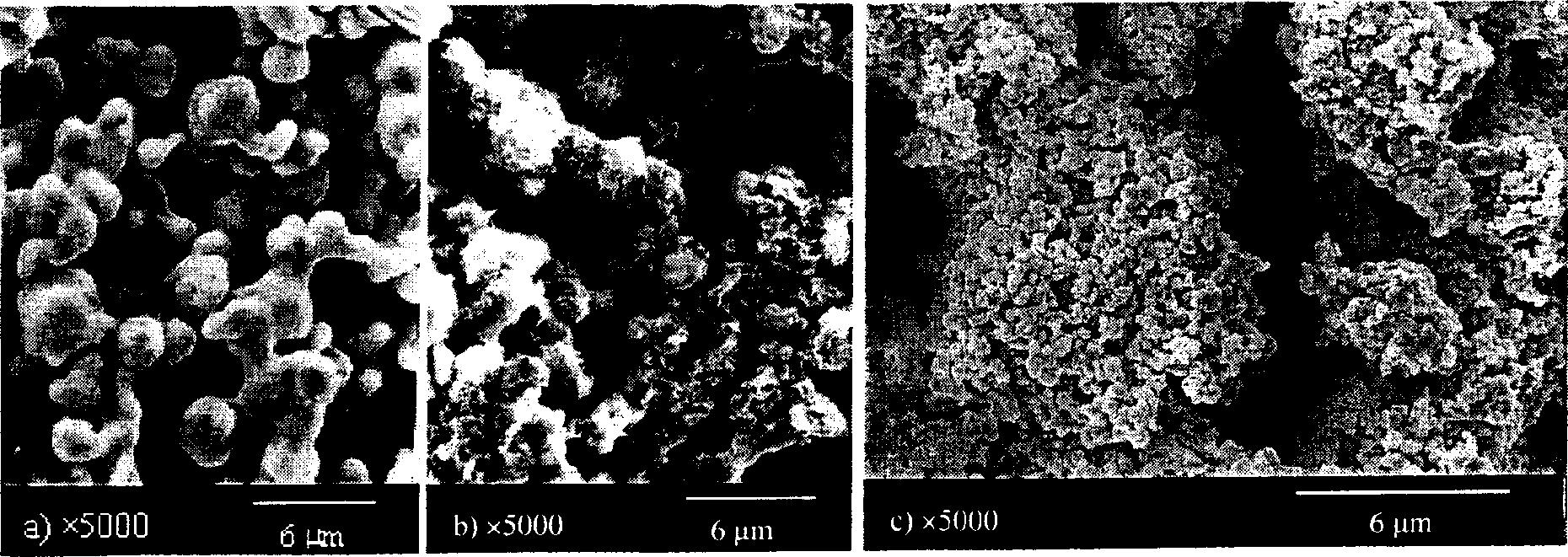

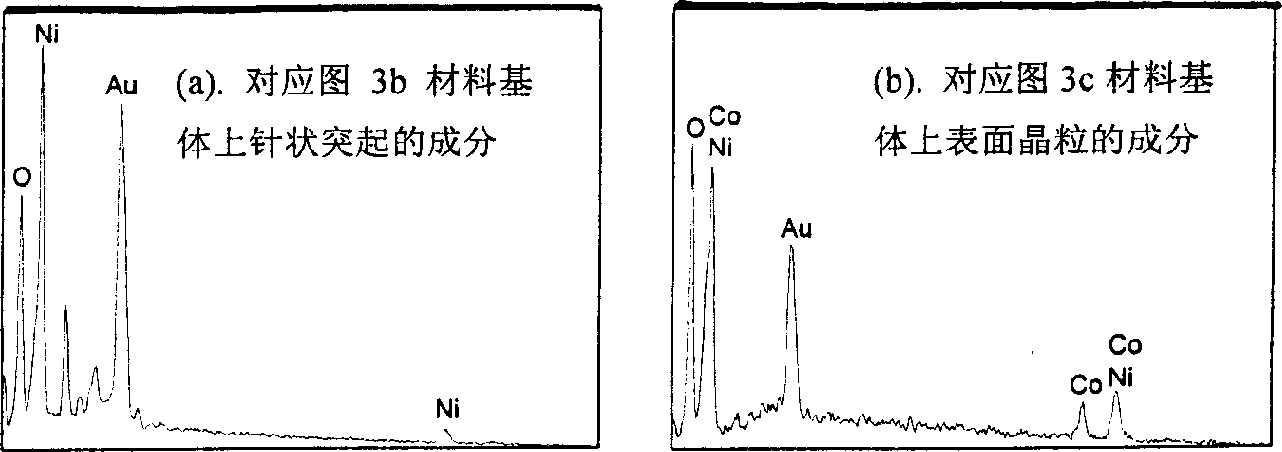

[0026] Figure 5 The curves in each represent porous Ni(a), LiCoO 2 -Ni composite (b) and Ni-LiCoO after pre-oxidation 2 Composites (c) in molten carbonate and (CO 2 +O 2 +N 2 ) in a mixed atmosphere at 923K and 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com