Manganese-zinc ferrite magnetic core mfg. method

A technology of manganese-zinc ferrite and its manufacturing method, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials of inorganic materials, electrical components, etc., can solve the problems of long manufacturing cycle, large consumption of heating elements and refractory materials, etc. Effects of low cost, high saturation flux density, and low core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

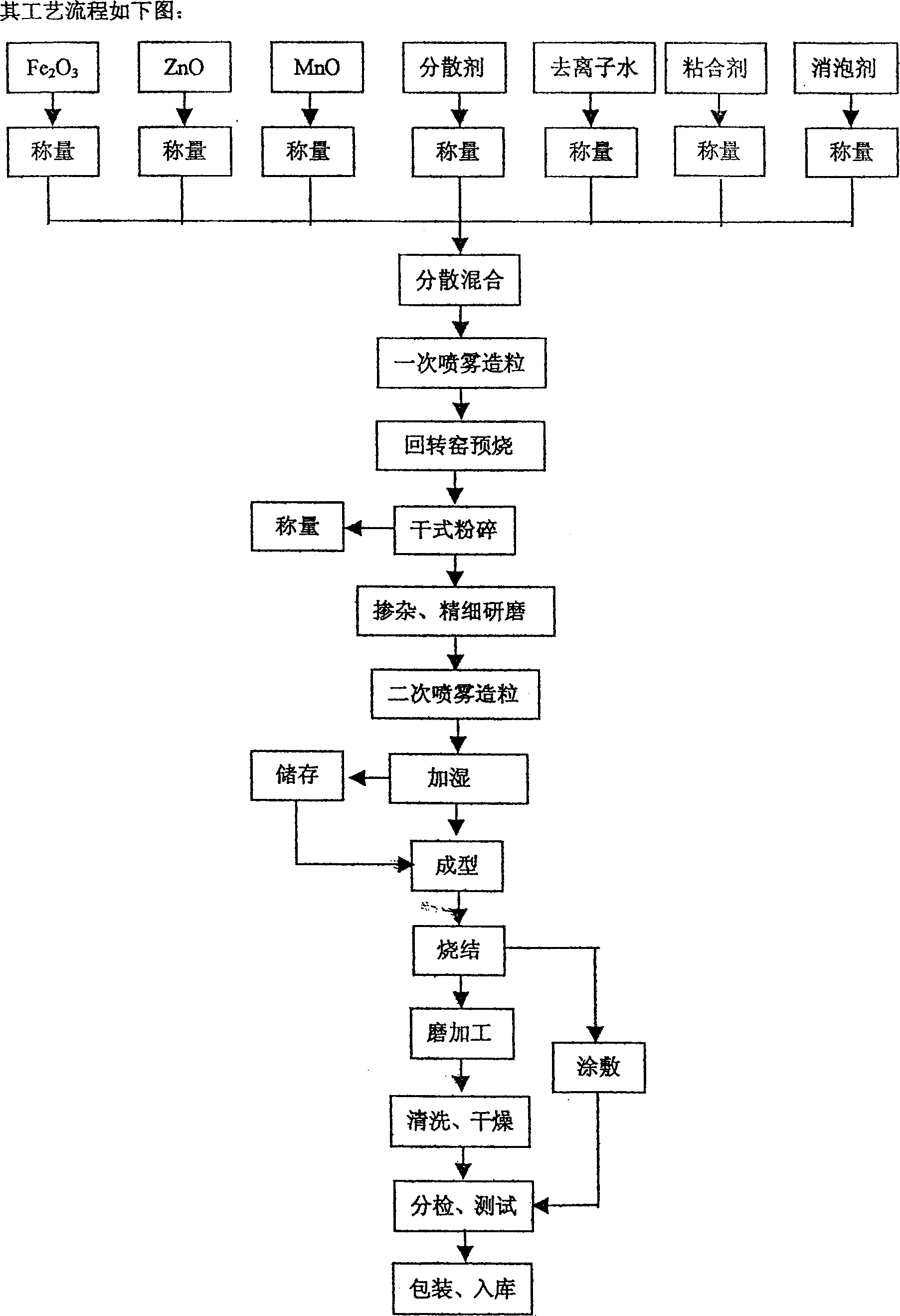

Method used

Image

Examples

Embodiment 1

[0036] Fe with high silicon content 2 o 3 (53.3 mol%), ZnO (10 mol%) and MnO (36.7 mol%) were compounded as main components. At the same time, add dispersant: 0.5% by weight of polypropionic acid, defoamer: 0.2% by weight of n-octanol, 95% by weight of deionized water, binder: 0.45% by weight of polyvinyl alcohol solution, in a high-speed mixer Mixed for 75 minutes, the viscosity is 250-350cps. Through the spray drying mechanism, the average particle size is about 100 microns, the moisture content is less than 0.1% by weight, and the flow angle is less than 40 degrees; it is pre-fired in a rotary kiln at a temperature of 900 ° C for a certain period of time ;Perform dry or wet crushing for 25-35 minutes to make a powder with an average particle size of 1.5-2.0 microns; relative to the above powder, add: additive: calcium oxide (CaO): 0.01-0.05% by weight; Deionized water is 70% by weight; dispersant: polypropionic acid is 0.4% by weight; defoamer: n-octanol is 0.2% by weigh...

Embodiment 2

[0047] In the composition of the manganese-zinc-based ferrite in Example 1, Nb may be contained in addition to CaO as the main component as an additive component. 2 o 5 , V 2 o 5 and TiO 2 Samples 9-20 were obtained by using the method prepared in Example 1. Each obtained sample was evaluated similarly to Example 1. The results are listed in Table 2

[0048] Table 2

Embodiment 3

[0050] Fe with high silicon content 2 o 3 (52.6 mol%), ZnO (12 mol%) and MnO (35.4 mol%) were compounded as main components. At the same time, add dispersant: 0.4% by weight of polypropionic acid, defoamer: 0.3% by weight of n-octanol, 95% by weight of deionized water, binder: 0.3% by weight of polyvinyl alcohol solution, in a high-speed mixer Mix for 70 minutes to make a slurry with a viscosity of 250-350CPS. Through the spray drying mechanism, the average particle size is about 100 microns, the moisture content is less than 0.1% by weight, and the flow angle is less than 40 degrees; put it in the rotary kiln for pre-calcination, the pre-calcination temperature is 860 ° C, and the pre-fires for a certain period of time; Carry out dry or wet pulverization for 25-35 minutes to make a powder with an average particle size of 1.5-2.0 microns; relative to the above powder, add: additive calcium oxide (CaO): 0.01-0.15% by weight; deionized Water is 70% by weight; dispersant: poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation flux density | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com