Thin film type cathode and grid as well as its preparation method

A film-type, cathode-grid technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube cold cathode, etc., can solve the problems of high cost, environmental pollution, low efficiency, etc., and achieve high yield, low material cost, and manufacturing The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

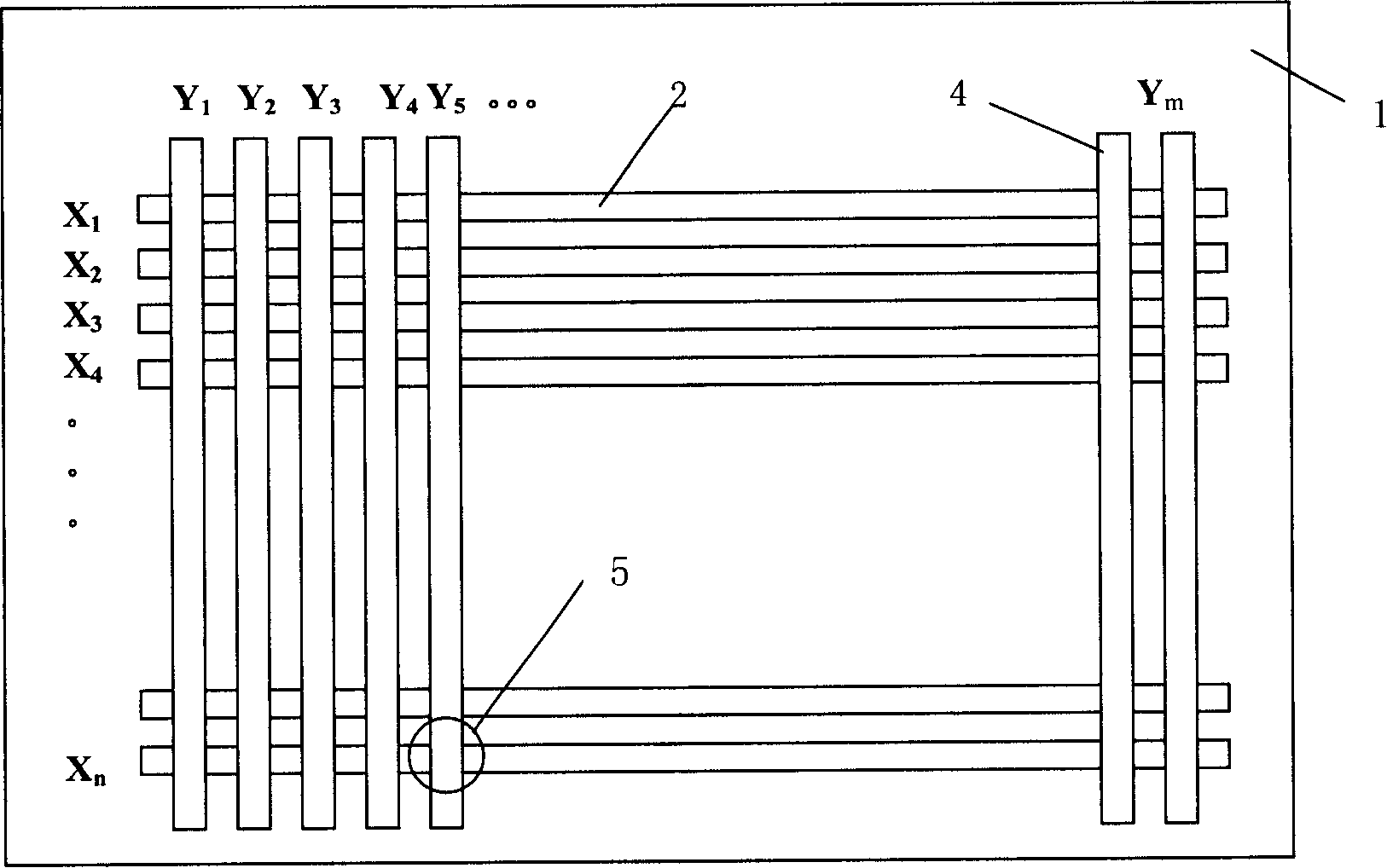

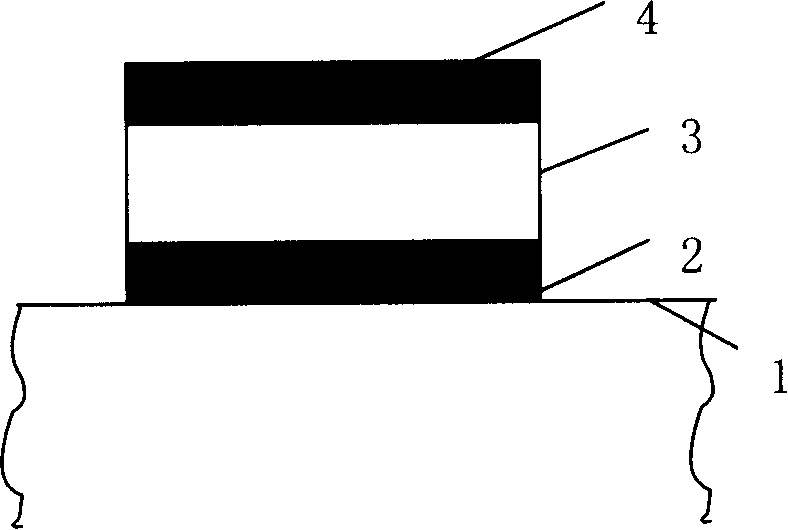

[0027] Such as Figure 1 and Figure 2 As shown, the formation process of the metal lower electrode of the cathode grid of the present invention includes: the glass substrate 1 adopts ordinary soda-lime silicate series flat glass, and the glass substrate 1 is annealed and cleaned before film deposition to obtain a clean coating surface; First sputter a chromium (titanium) film on the glass substrate 1 with direct current sputtering as a bottom film, and use direct current sputtering to sputter a copper film on the chromium (titanium) film to form a chromium (titanium)-copper double-layer composite film, which is fully Utilize the characteristics of strong adhesion between chromium (titanium) film and glass substrate and strong conductivity of copper film; use screen printing to print anti-etching protective ink on chromium (titanium)-copper double-layer composite film; and then chemical corrosion treatment Corrosion removes the chromium (titanium)-copper metal film without in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com