Superconducting wire and its preparation method

A superconducting wire, superconducting technology, applied in superconducting/high-conducting conductor, usage of superconducting element, superconducting device, etc. The effect of improving welding performance, adding special functions, and improving protective ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

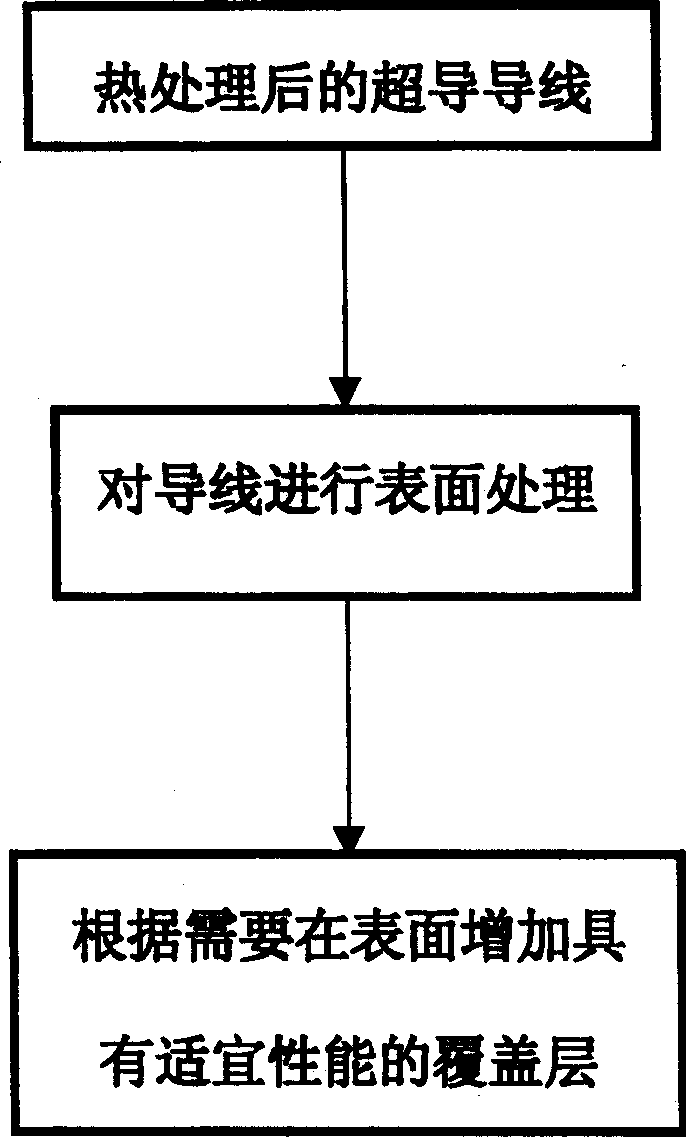

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 palladium plating

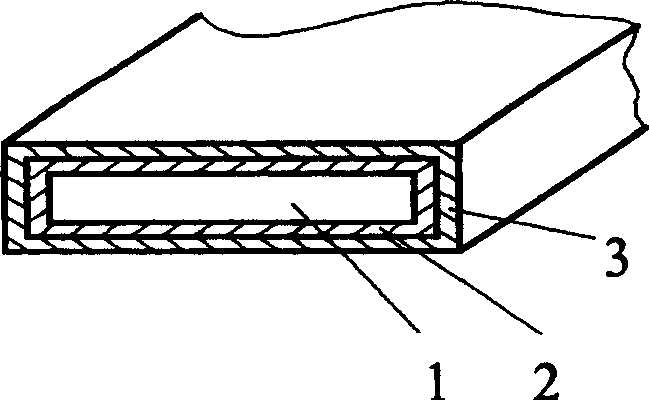

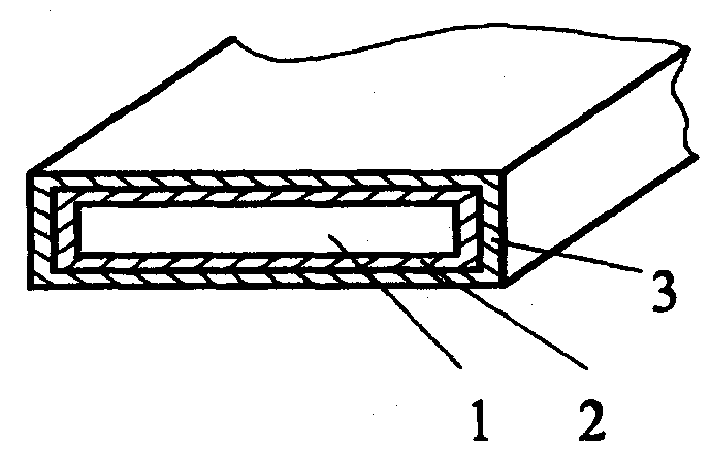

[0024] like figure 1 As shown, according to the metal casing method, the superconducting powder is put into the silver casing and subjected to drawing, rolling and heat treatment, and the engineering critical current density is 8000A / cm 2 (77K, self-field) superconducting wire, and then use a 300-mesh emery cloth wheel to grind the surface of the wire. The diameter of the emery cloth wheel is 60mm, and the speed is 10000 rpm. The rotation speed is 20000 rpm, then use acetone to degrease the surface of the wire, and then wash it with cold and hot water, and then use sulfuric acid with a concentration of 16mL / L to carry out weak corrosion at room temperature for 5 seconds, and then use chlorine The palladium chloride solution electroplates a layer of palladium on the surface of the wire. The content of the palladium chloride solution in the electrolyte is 3.7g / L, the content of disodium hydrogen phosphate is 100g / L, the content of diammon...

Embodiment 2

[0025] Example 2 Tin plating

[0026] According to the metal casing method, the superconducting powder is put into the silver casing and subjected to drawing, rolling and heat treatment, and the engineering critical current density is 7000A / cm 2 (77K, self-field) superconducting wire, and then use a 300-mesh emery cloth wheel to grind the surface of the wire. The diameter of the emery cloth wheel is 60mm, and the speed is 10000 rpm. The rotating speed is 36000 rpm, then use alcohol to remove oil, and then use sulfuric acid with a concentration of 20mL / L to weakly corrode at room temperature for 4 seconds, then wash with warm water and cold water in turn, and then electroplate tin, the electrolyte is 70g / L stannous sulfate, 160g / L sulfuric acid and 40g / L brightener, and finally wash with warm water and dry. In this way, a layer of tin film is obtained on the surface of the wire, which can effectively enhance the oxidation resistance, penetration resistance, mechanical strengt...

Embodiment 3

[0027] Example 3 Tin and Epoxy

[0028] According to the metal casing method, the superconducting powder is put into the silver casing and subjected to drawing, rolling and heat treatment, and the engineering critical current density is 8000A / cm 2 (77K, self-field) superconducting wire, and then use a 300-mesh emery cloth wheel to grind the surface of the wire. The diameter of the emery cloth wheel is 60mm, and the speed is 10000 rpm. The rotating speed is 36000 rpm, then use alcohol to remove oil, and then use sulfuric acid with a concentration of 20mL / L to weakly corrode at room temperature for 4 seconds, then wash with warm water and cold water in turn, and then electroplate tin, the electrolyte is 70g / L stannous sulfate, 160g / L sulfuric acid and 40g / L brightener, and finally wash with warm water and dry. The prepared wire was then dip-coated in an organic epoxy resin solution, and cured in air at 240° C. for 5 minutes, thereby forming a resin layer on the superconducting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com