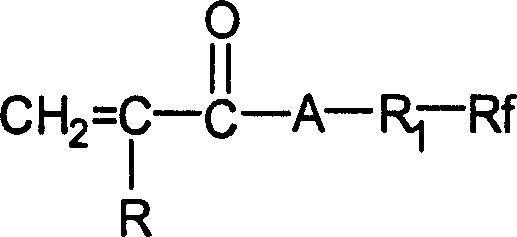

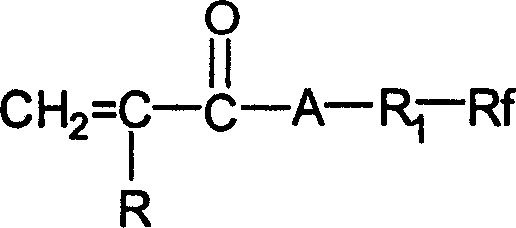

Aqueous emulsion type fluorine containing water repellent oil repellent agent and its preparation method

A water-and-oil-repellent, water-emulsion-type technology is applied in the field of water-emulsion-containing fluorine-containing water and oil-repellent and its preparation to achieve the effects of excellent water and oil repellency, fast polymerization speed and low polymerization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Mix the following ingredients in a 200 ml beaker: 30 g perfluoroalkylethyl methacrylate, 10 g laurate acrylate, 8 g butyl methacrylate, 1 g N-methylolacrylamide, 1 g hydroxypropyl methacrylate, Dodecyl mercaptan 0.25g, sodium lauryl sulfate 1.5g, alkylphenol polyoxyethylene ether-10 0.5g, deionized water 170g, placed in SK1200H type ultrasonic cleaner for pre-emulsification for 1 hour, to obtain stable water dispersion. Add the pre-emulsion to a glass reactor equipped with a stirrer, a thermometer and a condenser, then add 0.3 g of sodium bicarbonate, 0.3 g of potassium persulfate, 0.15 g of sodium bisulfite, and 0.025 g of copper sulfate, and pass through nitrogen to remove oxygen. Stir and heat, and the temperature of the water bath is raised to 50°C. After 3 minutes, opalescence appears, and the reaction is continued for 5 hours to obtain about 223 g of latex with a solid content of 23.5%.

Embodiment 2

[0059] Mix the following ingredients: 35 g perfluoroalkylethyl acrylate, 13 g stearyl acrylate, 1 g N-methylolacrylamide, 1 g hydroxyethyl acrylate, 0.25 g dodecyl mercaptan, 0.25 g octadecyltrimethyl 1.5 g of ammonium chloride and 160 g of deionized water were placed in a USC-102 ultrasonic cleaner for pre-emulsification for 0.5 hours to obtain a stable aqueous dispersion. Add the pre-emulsion into a glass reactor equipped with a stirrer, a thermometer and a condenser, then add 0.3 g of sodium bicarbonate, 0.3 g of ammonium persulfate, and 0.15 g of sodium bisulfite, pass nitrogen to deoxygenate, stir and heat to a water bath at 45 ℃ for 5 hours to obtain about 183 g of latex with a solid content of 28.6%.

Embodiment 3~8

[0061] Prepare fluorine-containing emulsion substantially according to the method for embodiment 1 or 2, and its monomer composition formula is listed in table 1:

[0062] The monomer consumption (parts by weight) in the embodiment 3-8 of table 1

[0063] Monomer 3 4 5 6 7 8

[0064] Perfluoroalkylethyl acrylate 70 80 50 - - -

[0065] Perfluoroalkylethyl methacrylate - - - 60 70 60

[0066] Lauryl Acrylate 20 - 30 25 - 30

[0067] Acrylic stearate 20 - - 30 -

[0068] Vinylidene chloride 10 0 20 15 0 10

[0069] 2-Hydroxyethyl acrylate - 2 - - 2

[0070] 3-Hydroxypropyl methacrylate 2 - - 2 - -

[0071] N-Hydroxyacrylamide 2 2 2 2 2 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com