Trace quantity sodium ion automatic rapid determination method and apparatus

A rapid determination and sodium ion technology, applied in the field of chemical analysis and quantification, can solve the problems of slow analysis speed, large sample consumption, poor analysis result precision, reproducibility and accuracy, etc., to eliminate the influence of electrode active surface , prolong the service life, the effect of fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

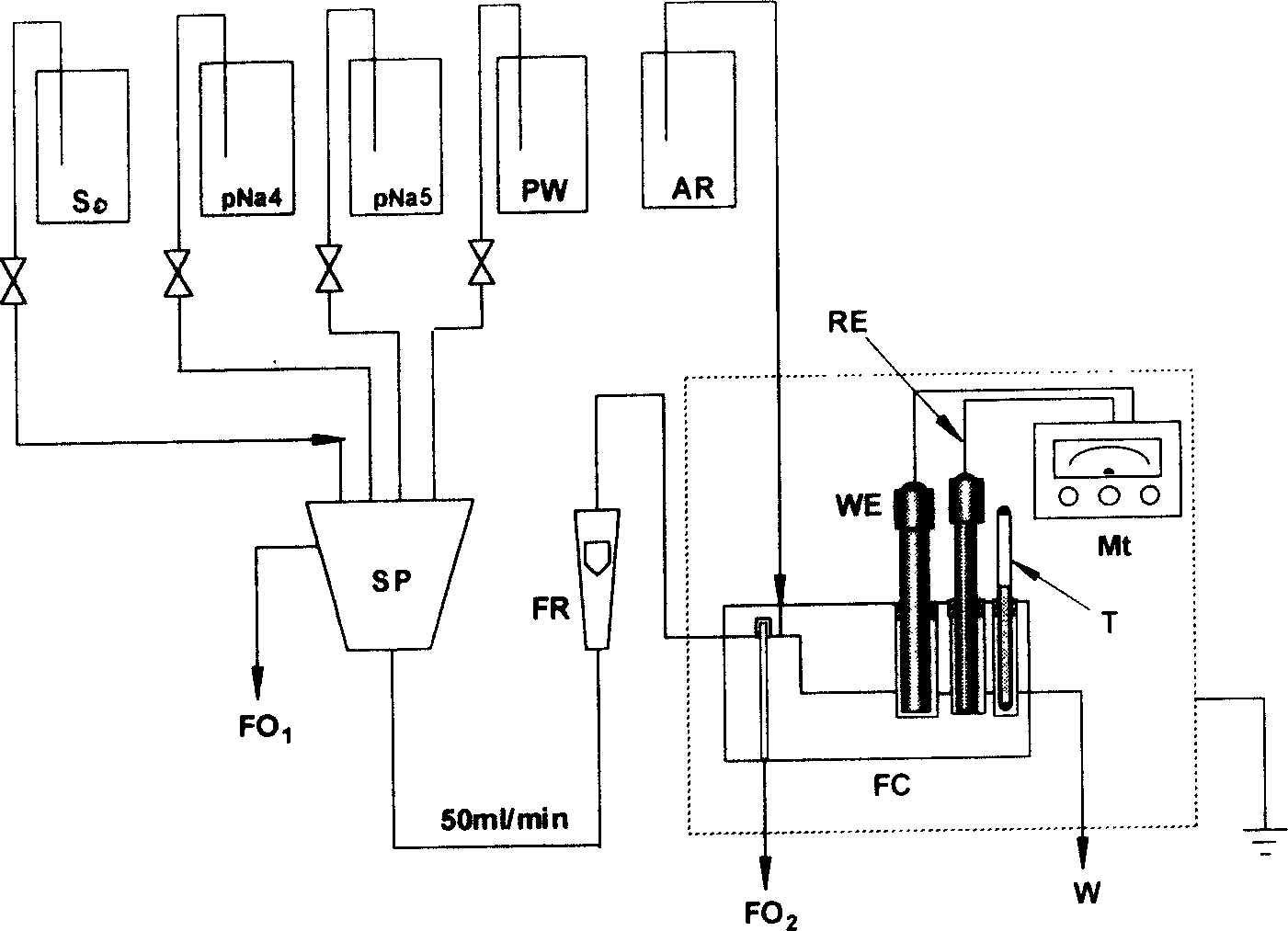

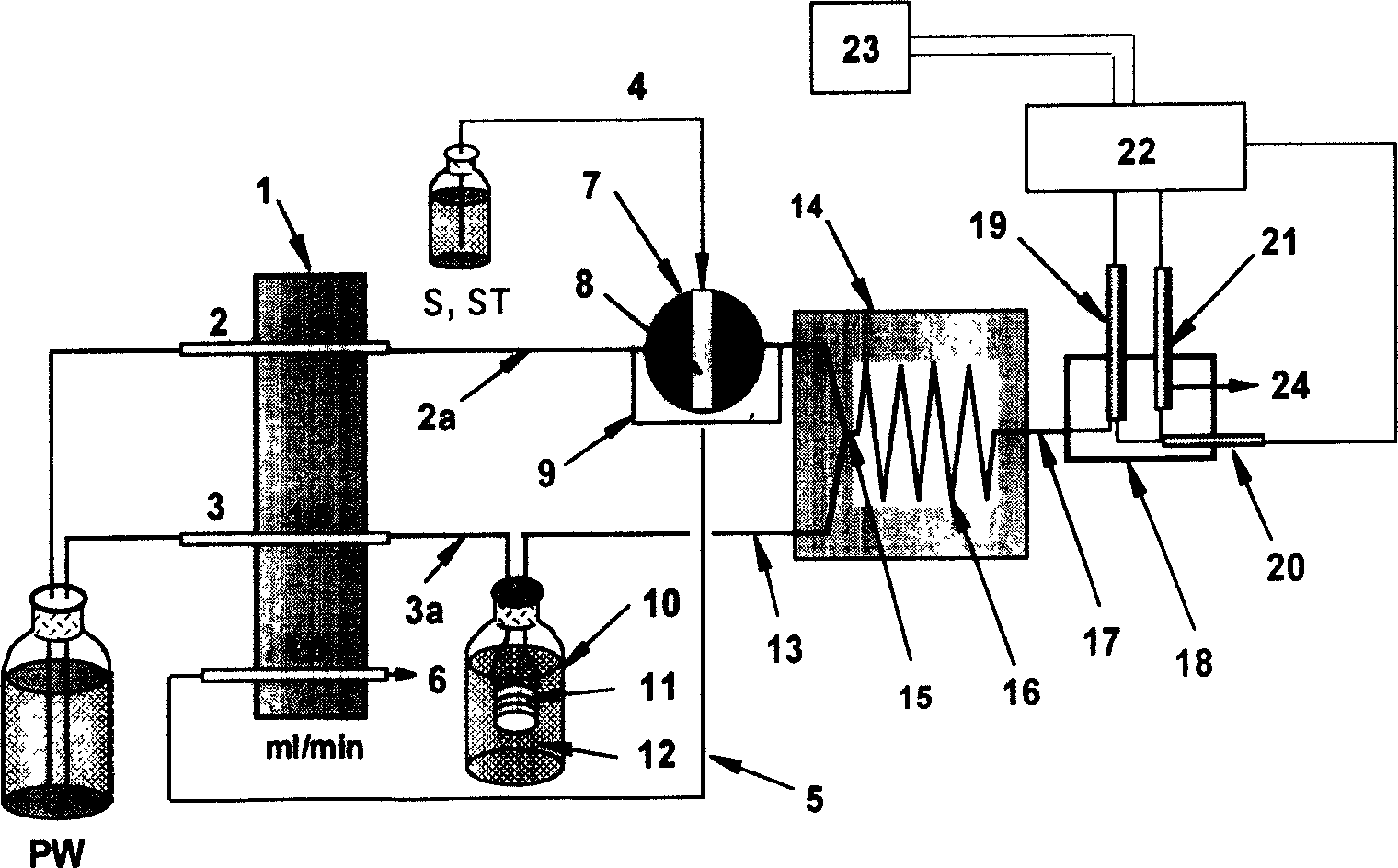

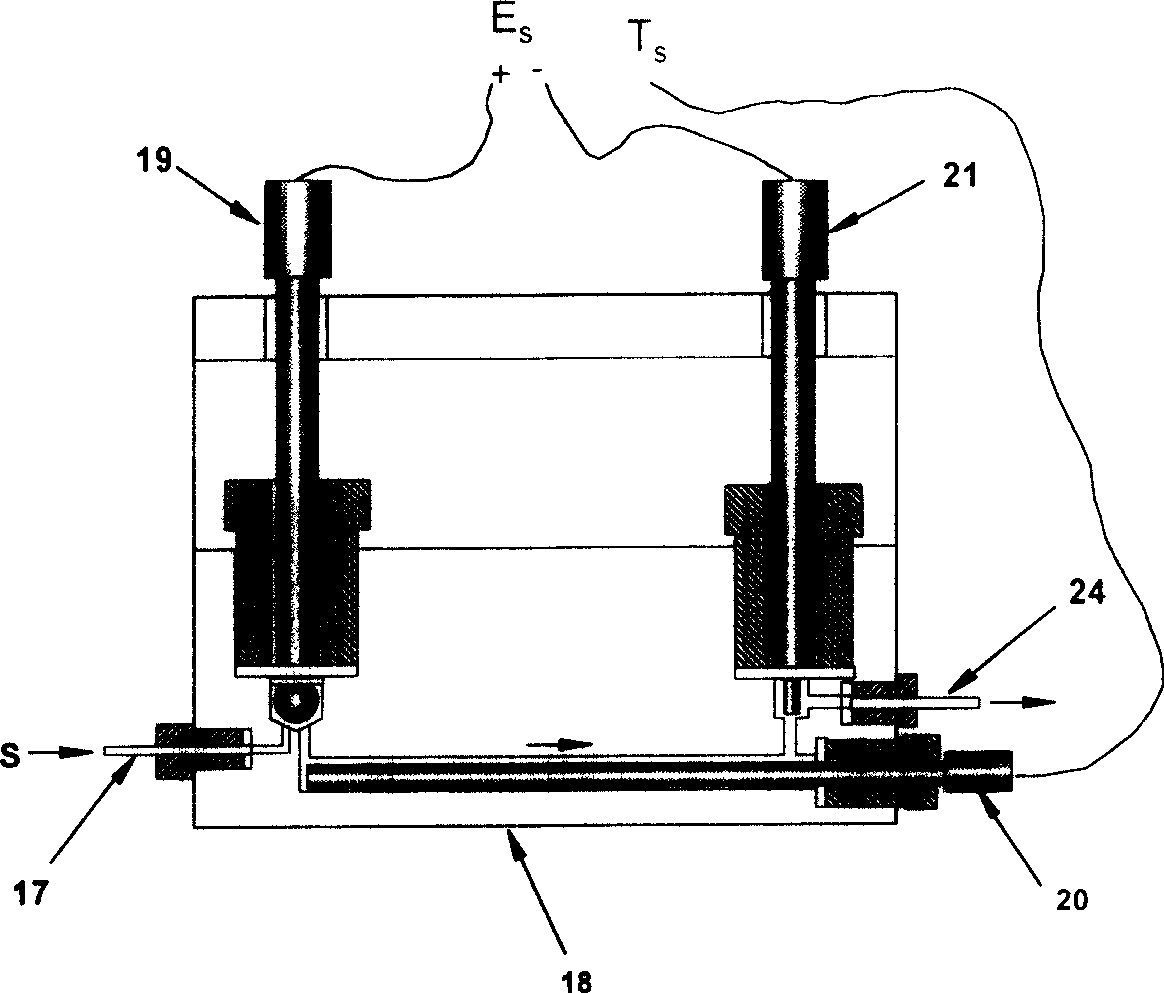

[0050] Utilize method and device of the present invention (see figure 2) Determination of trace sodium ions in boiler water and steam of a power plant. Experimental conditions: the alkalizing agent (12) is 60% diisopropylamine; the semipermeable membrane alkalization tube (11) has used a long 65cm, 0.6mm inner diameter silicone rubber tube with a semipermeable membrane function; Conductivity is the ultrapure water below 0.06 μ S / cm; Reaction coil pipe (16) has used the long 200cm, the polyethylene pipe of inner diameter 0.5mm; Function combination block (14) and flow type electrochemical detector (18) (see image 3 ) has used organic glass material to make; Sodium selective electrode (19) has used 23-8S type glass sodium electrode; Reference electrode (21) has used 001S type calomel electrode; Temperature sensor (20) is TDS-110 type temperature Sensor; Sodium ion processor (22) is DWG-9323A type ion meter; Recorder (23) is XWT-100 desktop automatic balance recorder.

[0051...

Embodiment 2

[0055] In this embodiment, different concentrations of sodium ion standard solutions are used to determine the influence of the injection volume on the sensitivity at room temperature. from Figure 8 It can be seen that with the increase of the injection volume, the sensitivity gradually increases; when the injection volume reaches above 0.80ml, the increase of the peak height tends to be gentle.

Embodiment 3

[0057] This embodiment is to measure the influence of current carrying capacity on sensitivity. When using a single-line analysis device ( Figure 4) , the effect of current carrying capacity on the response peak height is as follows Figure 9 shown. The three curves in the figure are the peak heights measured with sodium standard samples of different concentrations respectively. With the increase of the carrying flow, the peak height increases, but when the carrying flow reaches 3.0ml / min, the peak height increases slowly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com