Soybean oligopeptide production process and enzyme hydrolysis reaction kettle for realizing said process

A production process, soybean oligopeptide technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc. The effect of content, small molecular weight and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

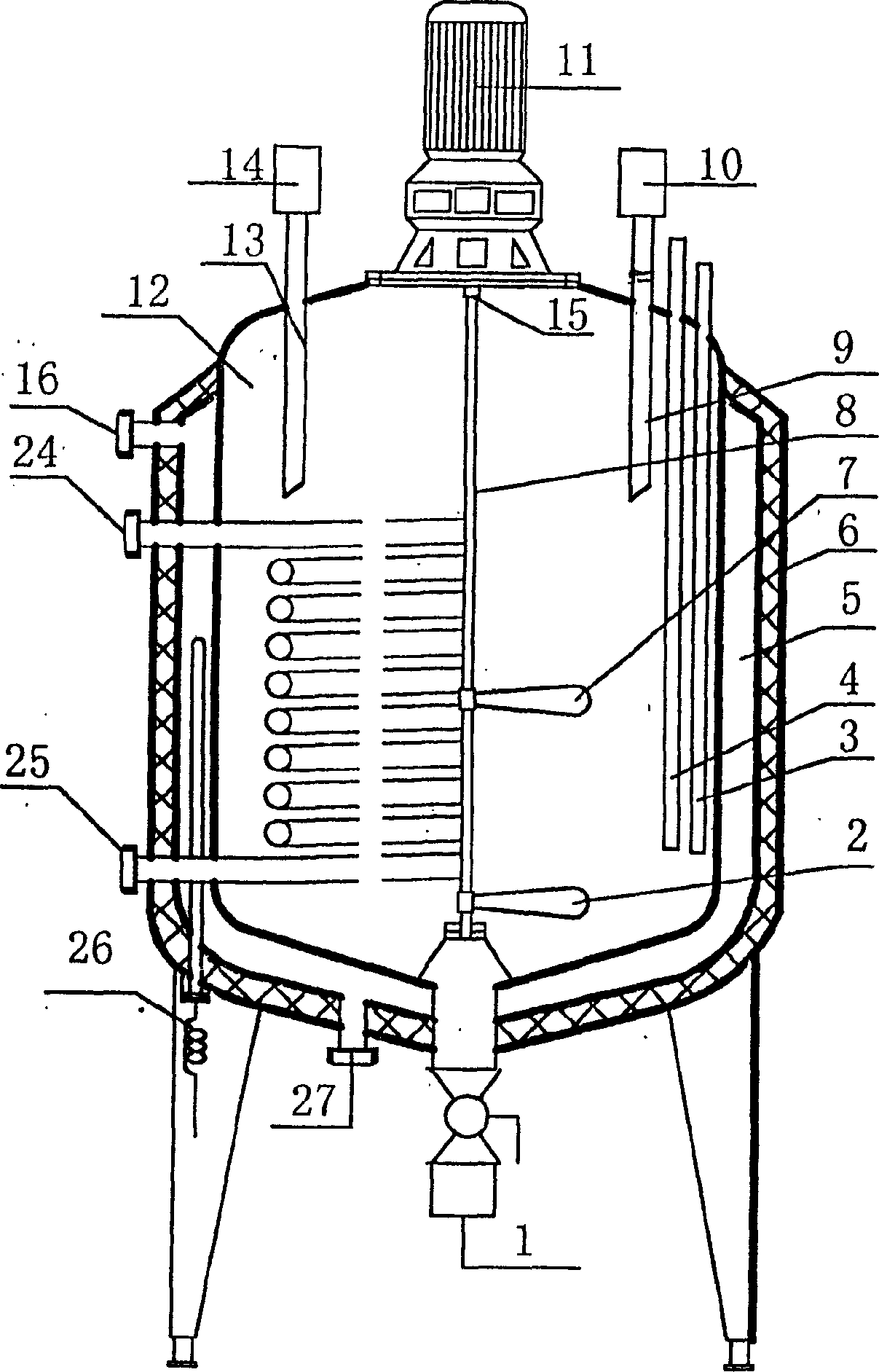

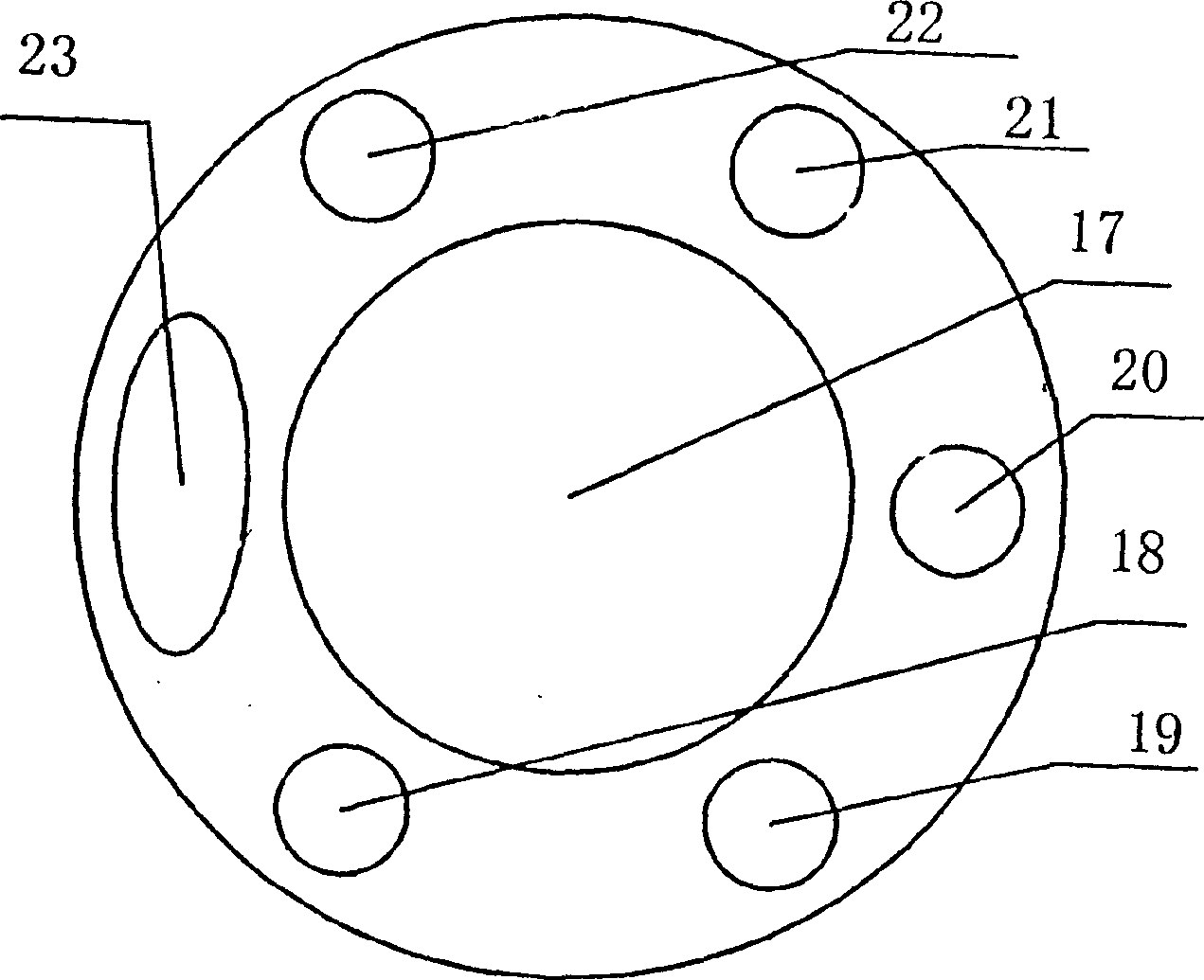

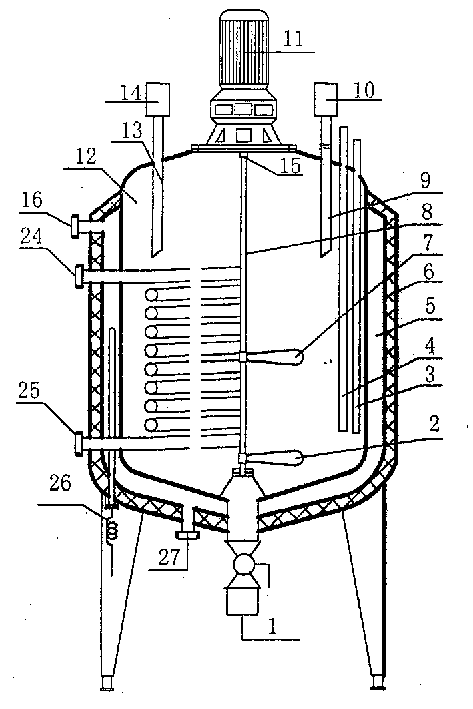

Method used

Image

Examples

Embodiment 1

[0022] Weigh 20 kg of soybean protein isolate, mix and dissolve it with pure water to form a slurry, add it to the enzyme hydrolysis reaction kettle, start the stirring device to stir the feed liquid, heat to 95°C, keep it warm for 30 minutes, then stop heating, and add circulating cooling water Cool the feed liquid to 40°C, slowly add 2N sodium hydroxide solution to the feed liquid until the pH value of the feed liquid is 8.0, add 2 kg of alkaline protease, and add alkali or acid dropwise according to the pH value of the acidity meter to ensure the pH value of the feed liquid 8.0 is unchanged to facilitate the smooth progress of the enzymatic hydrolysis reaction. The reaction is carried out under the conditions of constant temperature, constant PH value and constant stirring speed for 4 hours. Add 2 kg of flavor protease and continue the reaction for 5 hours. Heat to 95°C to kill the enzyme for 30 minutes. Cool down to 40°C, add 2 kg of activated carbon (200 mesh), continue to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com