PTMEG polymerization catalyst preparation method

A technology of catalyst and complexing agent, which is applied in the field of preparing 12-tungstophosphoric acid catalyst for PTMEG polymerization, which can solve the problems of polymerization catalytic activity, selective PTMEG product quality, yield less than 30%, and industrialization difficulties. , to achieve the effects of easy control, stable catalytic activity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

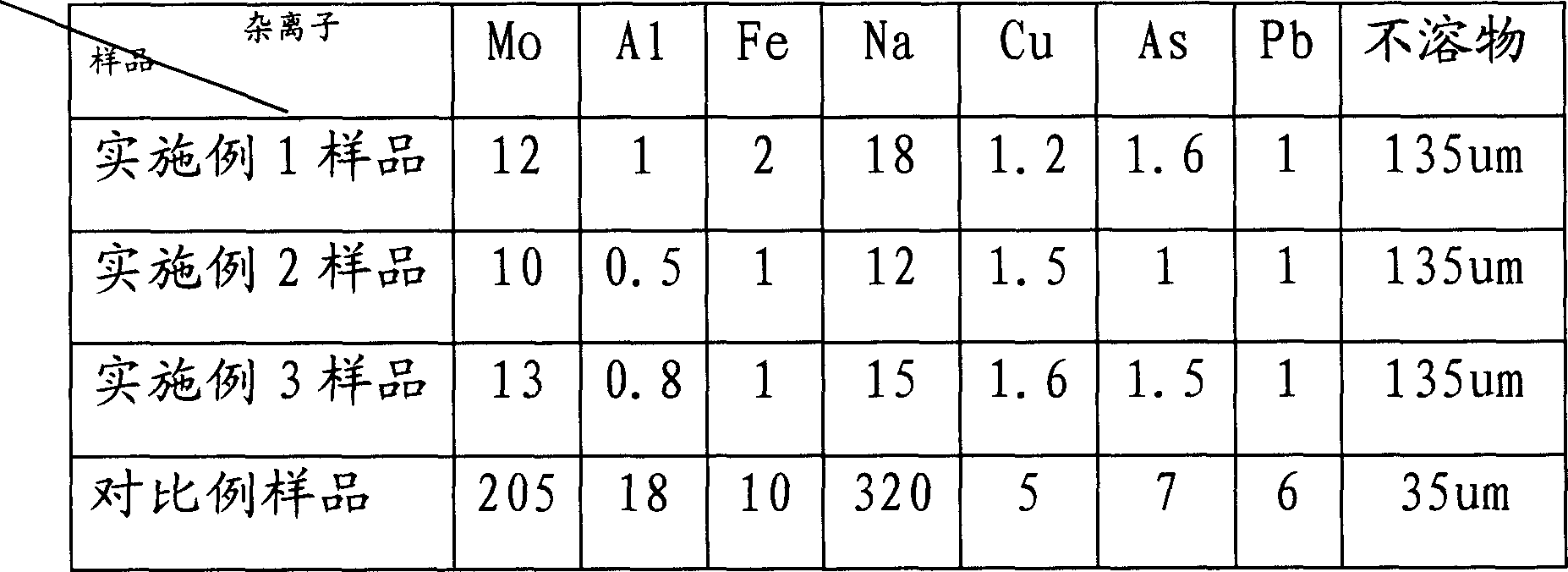

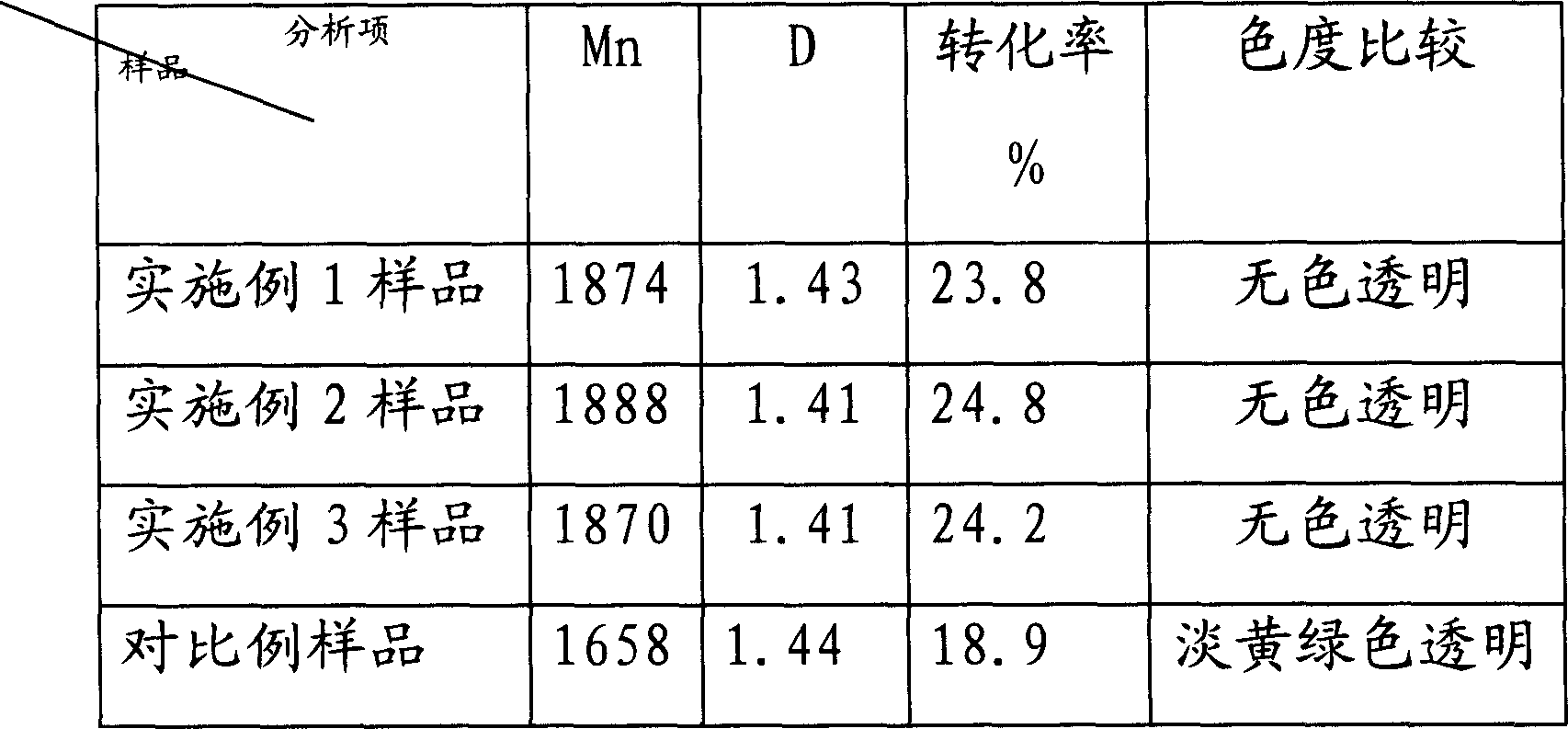

Embodiment 1

[0027] Weigh 509 grams of sodium tungstate and add it to a container containing 5200 mL of water to dissolve, add 30% H 2 o 2 Solution 120ml, stirring ice bath to cool down to 10°C, slowly add 0.75L of 6N hydrochloric acid, keep the temperature in the range of 6-8°C during the whole process, slowly introduce SO2 through the gas sparger 2 , after the reaction reaches the end point, use a Buchner funnel to suction and filter, wash the filter cake continuously through 4L of 1N, 0.6N, 0.2N dilute hydrochloric acid and 6L of deionized water, and immediately add the washed and filtered filter cake to 0.13mol / In the L phosphoric acid aqueous solution, the concentration of active tungstic acid is controlled at 1.15mol / L, fully stirred for 2 hours, and then slowly heated up to 50°C according to the heating curve. Cool the crystallizer for crystallization, centrifuge the 12-tungstophosphoric acid crystals containing a small amount of mother liquor, prepare the obtained crystals into a...

Embodiment 2

[0029] Weigh 509 grams of sodium tungstate and add it to a container containing 3200 mL of water to dissolve, add 30% H 2 o 2 Solution 107ml, stirring ice bath to cool down to 5°C, slowly add 0.68L of 6N hydrochloric acid, keep the temperature in the range of 4-5°C during the whole process, slowly introduce SO2 through the gas sparger 2 , after the reaction reaches the end point, use a Buchner funnel to suction and filter, wash the filter cake continuously through 4 L of 1N, 0.5 N, 0.1 N dilute hydrochloric acid and 6.5 L of deionized water, and immediately add the washed and filtered filter cake to 0.12 mol / L phosphoric acid aqueous solution, the concentration of active tungstic acid is controlled at 1.15mol / L, fully stirred for 2 hours, and then slowly heated up to 50°C according to the heating curve. Cool the crystallizer for cooling crystallization, centrifuge the 12-tungstophosphoric acid crystals containing a small amount of mother liquor, prepare the obtained crystals...

Embodiment 3

[0031] Weigh 1,000 grams of sodium tungstate and add it to a container containing 7,200 mL of water to dissolve it, add 30% H 2 o 2 Solution 219ml, stirring ice bath to cool down to 10°C, slowly add 1.6L of 6N hydrochloric acid, keep the temperature in the range of 7-10°C during the whole process, slowly inject SO through the gas sparger 2, after the reaction reaches the end point, use a Buchner funnel to suction and filter, wash the filter cake continuously through 10 L of 1N, 0.5 N, 0.1 N dilute hydrochloric acid and 12 L of deionized water, and immediately add the washed and filtered filter cake to 0.12 mol / In the L phosphoric acid aqueous solution, the concentration of active tungstic acid is controlled at 1.14mol / L, fully stirred for 3 hours, and then slowly heated up to 50°C according to the heating curve. The crystallizer is cooled and crystallized, and the 12-tungstophosphoric acid crystals containing a small amount of mother liquor are centrifuged, and the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com