Binary optica device grey scale changing mask method and device for making

A technology of gray scale mask and binary optics, which is applied in the direction of photolithographic exposure device, optics, and originals for photomechanical processing, etc., can solve the problems of complex process and high cost, and achieve high contrast characteristics and high gray scale Number, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

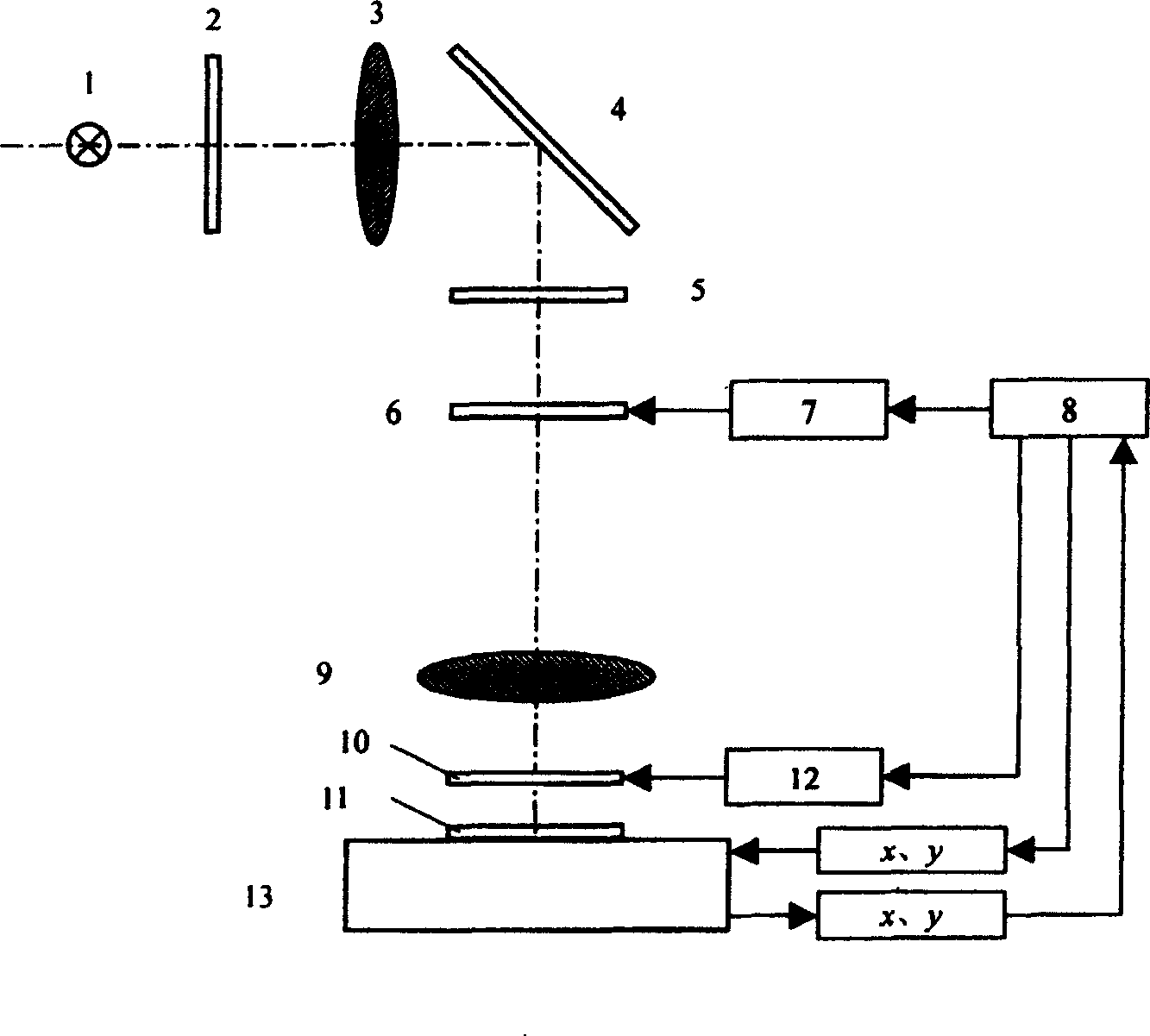

[0033] The key to the variable grayscale mask method is that it is difficult to quickly produce a high-precision grayscale mask with different grayscale levels to precisely control the exposure. The invention proposes a grayscale mask manufacturing method based on a spatial light modulator, which adopts pattern-by-pattern exposure, which can overcome the shortcomings of slow speed and high cost of direct writing grayscale masks by lasers and electron beams, and at the same time utilizes the high Features such as resolution, high gray scale number and high contrast can make the minimum feature size of the gray scale reticle reach the micron or even sub-micron level. The present invention is characterized in that it connects the spatial light modulator with the computer through the video driver, and the computer controls and inputs the video signal, the light beam emitted by the point light source becomes parallel light after passing through the condenser lens, and the vertical i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com