Manufacturing method of lithium ion battery positive electrode material

A technology for lithium ion batteries and cathode materials, which is applied in the field of material synthesis, can solve the problems of uneven phase, wide particle size distribution, and poor phase structure stability of lithium manganese oxide products, and achieves easy industrial scale production, low price, The effect of reducing the high temperature capacity decay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

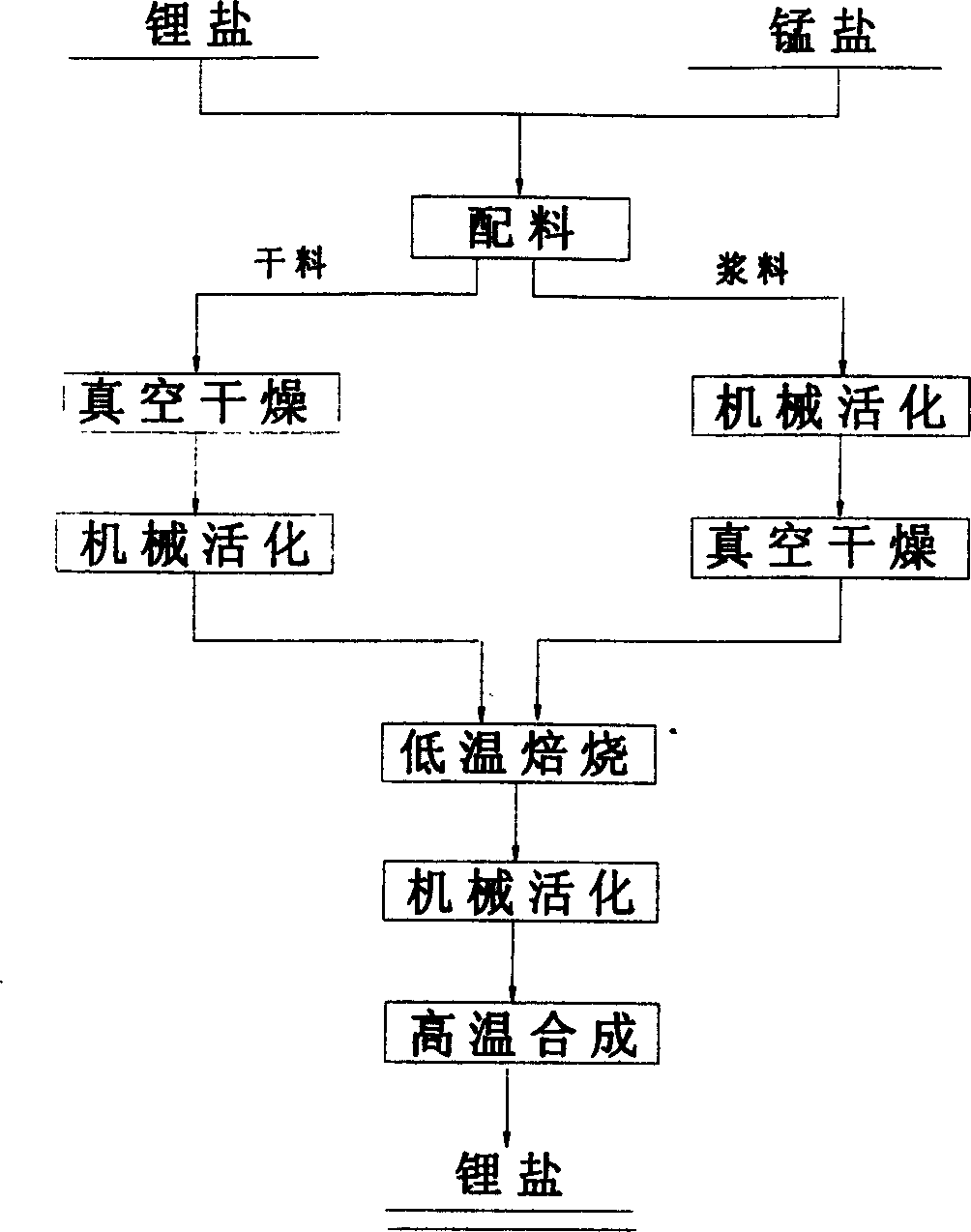

Method used

Image

Examples

Embodiment 1

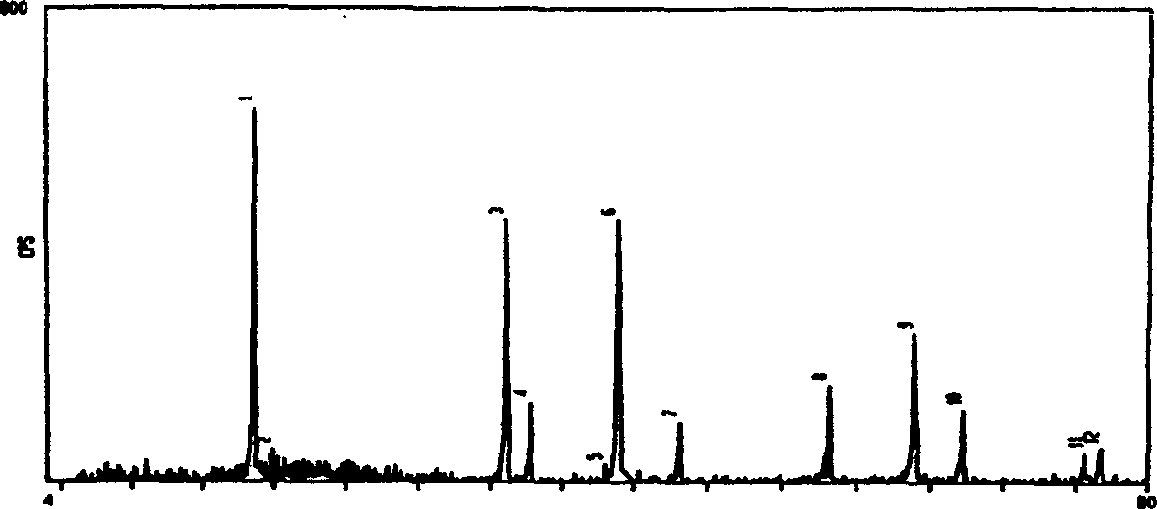

[0027] LiOH and Mn(NO 3 ) 2 Weigh the ingredients according to the molar ratio of Li / Mn of 0.95:2, dry them in vacuum at 120°C for 8 hours after mixing, put them into an agate ball mill jar after cooling, and ball mill them on a planetary mushroom machine at a speed of 450r / min , perform mechanical activation treatment for 15 hours, then pretreatment at constant temperature at 450°C for 6 hours, ball mill activation for 30 minutes after cooling, and then synthesize at constant temperature at 700°C for 36 hours, and obtain spinel LiMn after natural cooling in the furnace 2 o 4 Cathode material. For the obtained spinel LiMn 2 o 4 X-ray diffraction analysis, scanning electron microscopy, and laser particle size analysis were carried out on the positive electrode material. The test results are shown in figure 2 , 3 , 4.

[0028] The electrochemical performance test of the material was assembled into a double-electrode simulated battery. Positive electrode according to LiM...

Embodiment 2

[0030] LiNO 3 and MnCO 3 Weigh the ingredients according to the molar ratio of Li / Mn of 1:2, dry in vacuum at 150°C for 6 hours after preparation, put it into an agate ball mill jar after cooling, and ball mill at a speed of 500r / min on a planetary mushroom machine , perform mechanical activation treatment for 18 hours, then pretreat at 450°C for 10 hours at a constant temperature, after cooling, ball milling for 1.5 hours, and then synthesize at a constant temperature at 800°C for 30 hours, and then naturally cool in the furnace to obtain spinel LiMn 2 o 4 Cathode material. For spinel LiMn 2 o 4 X-ray diffraction analysis, scanning electron microscopy, and laser particle size analysis were carried out on the positive electrode material. The test results are shown in Image 6 , 7 ,8.

[0031] The electrochemical performance test and assembly conditions are the same as in Example 1. The test results show that the first discharge specific capacity is 121.59mAh / g, and the...

Embodiment 3

[0033] Will Li 2 CO 3 and electrolytic MnO 2 Weigh the ingredients according to the molar ratio of Li / Mn of 1.03:2, add ethanol to the prepared mixture and ethanol according to the mass ratio of 100:15 to make a slurry, put it into the agate ball mill jar and put it on the planetary mushroom machine Ball mill at a rate of 600r / min, and perform mechanical activation treatment for 25 hours. After ball milling, put it into a vacuum drying oven to dry at 180°C to remove ethanol, and ball mill the dried material for 30 minutes to form a powder. Then pretreatment at constant temperature at 450°C for 12 hours, after cooling, ball milling and activation for 2 hours, then synthesis at constant temperature at 800°C for 24 hours, and spinel LiMn was obtained after natural cooling in the furnace. 2 o 4 Cathode material. For spinel LiMn 2 o 4 X-ray diffraction analysis, scanning electron microscopy, and laser particle size analysis were carried out on the positive electrode material....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com