Process of making rare earth doped optical fibre

A rare earth, optical fiber technology, applied in manufacturing tools, glass manufacturing equipment, optics, etc., can solve problems such as unreliability and reproducibility, parameter sensitivity, and difficult to control porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

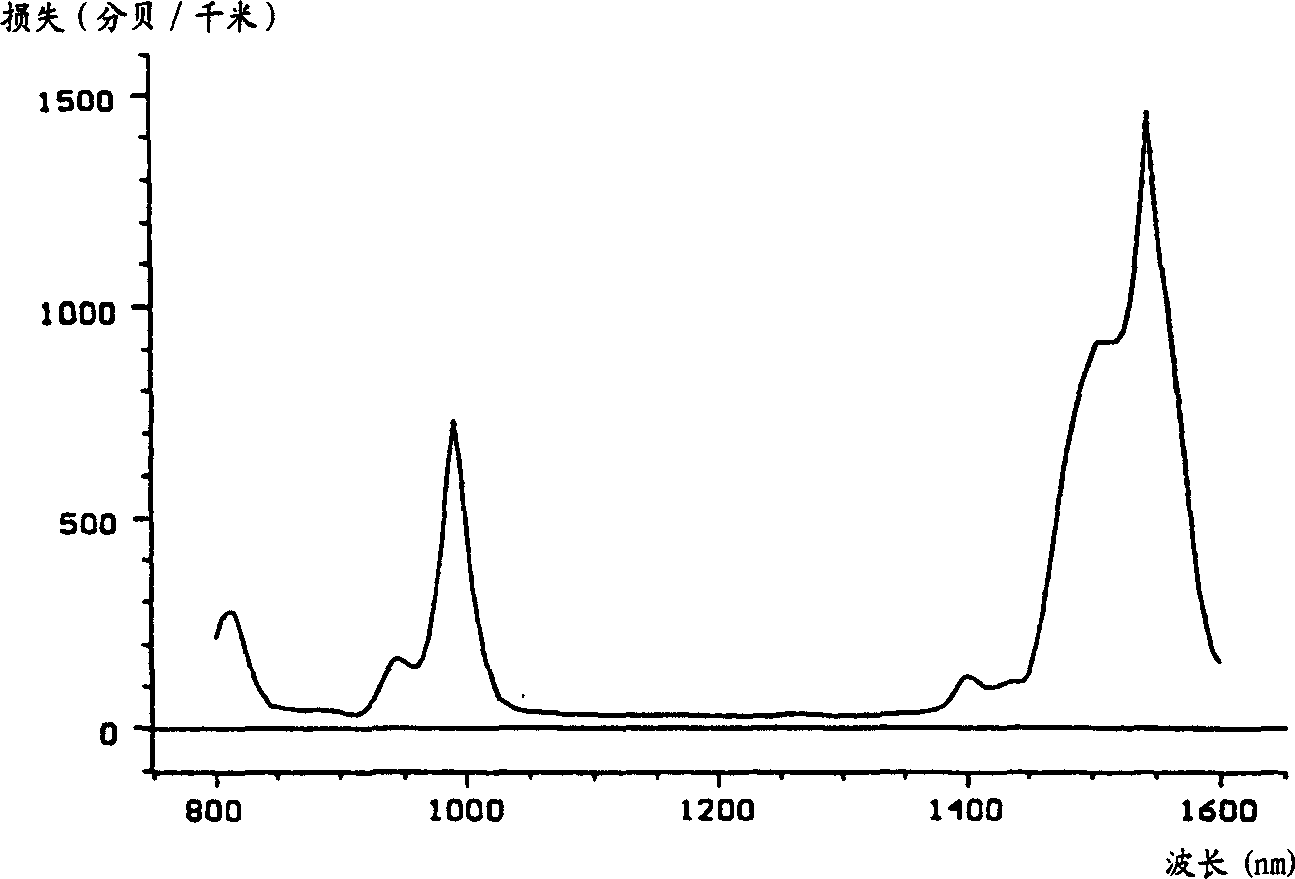

[0113] Er-doped fiber

[0114] Amorphous silica microspheres synthesized by hydrolysis of tetraethoxyorthosilicate (Stober method) were dispersed in an erbium nitrate solution (kept in an ice bath) under sonication so that 98.5 mol %SiO 2 and 1.5 mol% Er 2 o 3 , followed by the addition of aqueous ammonia by known methods. The resulting product was washed with water, then centrifuged and dried under vacuum.

[0115] ·The preparation composition is 94.98SiO 2 : 3GeO 2 : 2Al 2 o 3 :0.02Er 2 o 3 (equivalent oxide mole %) for coating the inner walls of high purity transparent fused silica glass tubes.

[0116] Diluted with 98.5 mol% SiO with a silica sol containing the desired amount of tetraethoxysilane (TEOS) 2 and 1.5 mol% Er 2 o 3 coated with erbium oxide (Er 2 o 3 ) of silicon dioxide powder, so that the composition is 94.98 equivalent oxide mol% SiO 2 and 0.02 equivalent oxide mole % Er 2 o 3 of silica sol.

[0117] In the presence of a mixed solvent of 1-...

Embodiment 2

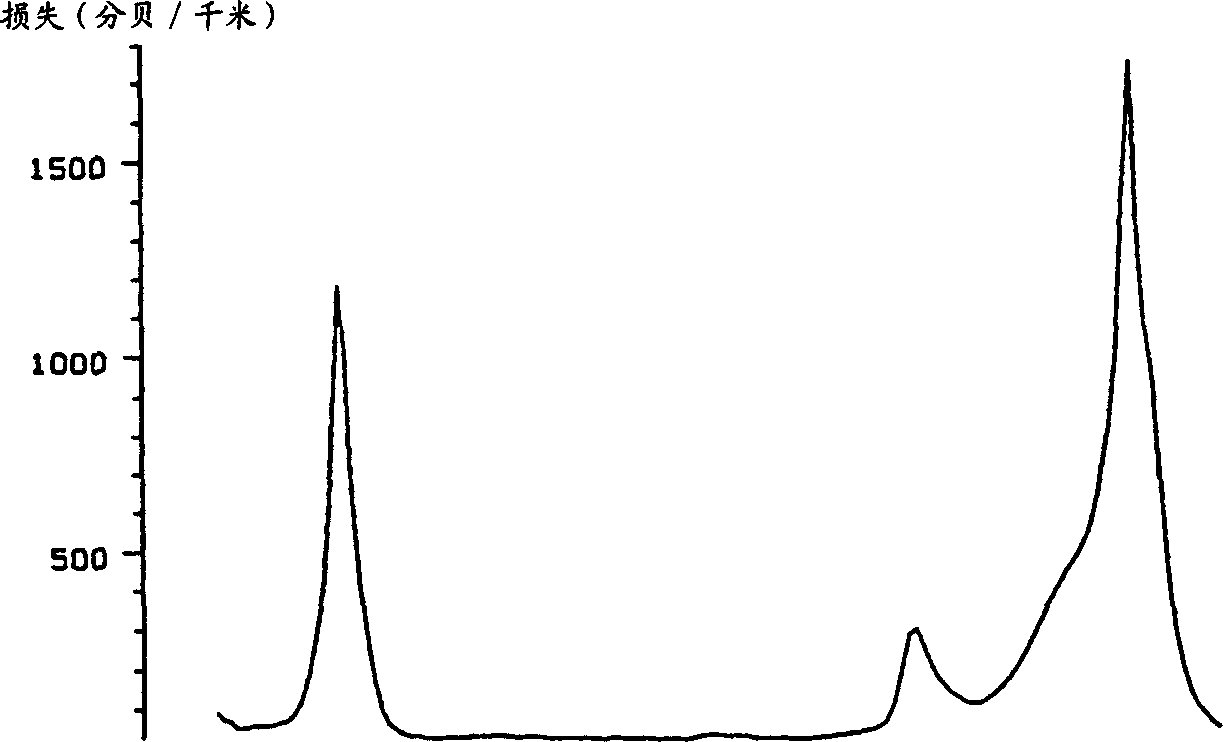

[0130] Nd-doped fiber

[0131] Amorphous silica microspheres synthesized by hydrolysis of tetraethoxyorthosilicate (Stober method) were dispersed in a neodymium nitrate solution (kept in an ice bath) under sonication so that 98.5 mol %SiO 2 and 1.5 mol% Nd 2 o 3 , followed by the addition of aqueous ammonia by known methods. The resulting product was washed with water, then centrifuged and dried under vacuum.

[0132] ·The preparation composition is 94.8SiO 2 : 3GeO 2 : 2Al 2 o 3 : 0.20Nd 2 o 3 (equivalent oxide mole %) for coating the inner walls of high purity transparent fused silica glass tubes.

[0133] Diluted with 98.5 mol% SiO with a silica sol containing the desired amount of tetraethoxysilane (TEOS) 2 and 1.5 mol% Nd 2 o 3 coated with neodymium oxide (Nd 2 o 3 ) of silicon dioxide powder, so that the composition is 94.8 equivalent oxide mol% SiO 2 and 0.20 equivalent oxide mol% Nd 2 o 3 of silica sol.

[0134] In the presence of a mixed solvent of ...

Embodiment 3

[0147] Eu doped fiber

[0148] Amorphous silica microspheres synthesized by hydrolysis of tetraethoxyorthosilicate (Stober method) were dispersed in a solution of europium nitrate (kept in an ice bath) under the action of sonication so that 99.0 mol %SiO 2 and 1.0 mol% Eu 2 o 3 , followed by the addition of aqueous ammonia by known methods. The resulting product was washed with water, then centrifuged and dried under vacuum.

[0149] ·The preparation composition is 95.99SiO 2 : 3GeO 2 : 1Al 2 o 3 : 0.01Eu 2 o 3 (equivalent oxide mole %) for coating the inner walls of high purity transparent fused silica glass tubes.

[0150] Diluted with 99.0 mol% SiO with a silica sol containing the desired amount of tetraethoxysilane (TEOS) 2 and 1.0 mol% Eu 2 o 3 coated with europium oxide (Eu 2 o 3 ) of silicon dioxide powder, so that the composition is 95.99 equivalent oxide mol% SiO 2 and 0.01 equivalent oxide mol% Eu 2 o 3 of silica sol.

[0151] In the presence of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com