Neutral red blended silicon dioxide nano biological biological sensor and its preparing method

A biosensor and silicon dioxide technology, applied in the direction of instruments, scientific instruments, and electrochemical variables of materials, can solve the problems of high enzyme consumption, high sensor cost, poor stability, etc., and achieve improved sensitivity and stability, good biological Compatibility and biocompatibility, effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

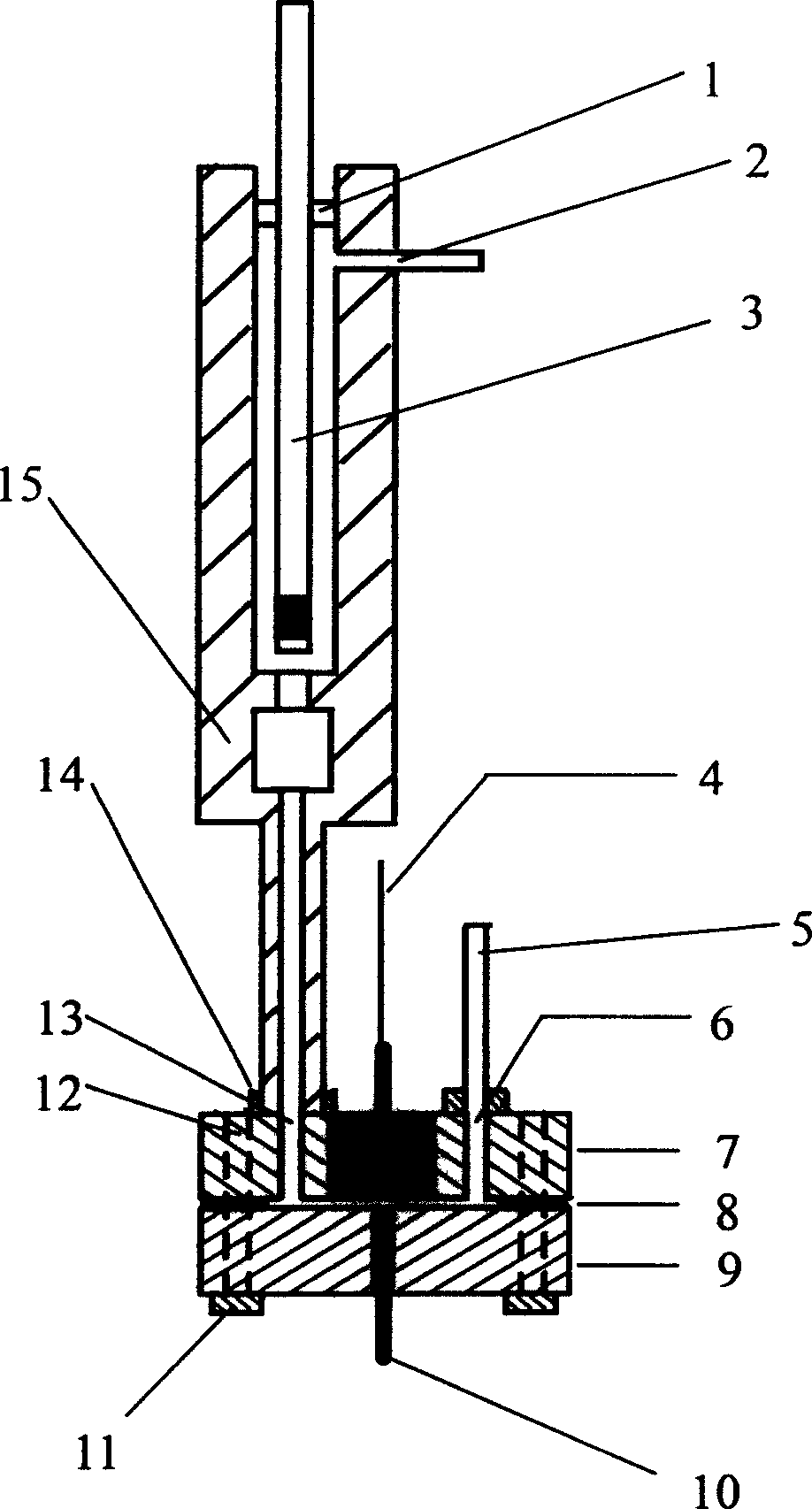

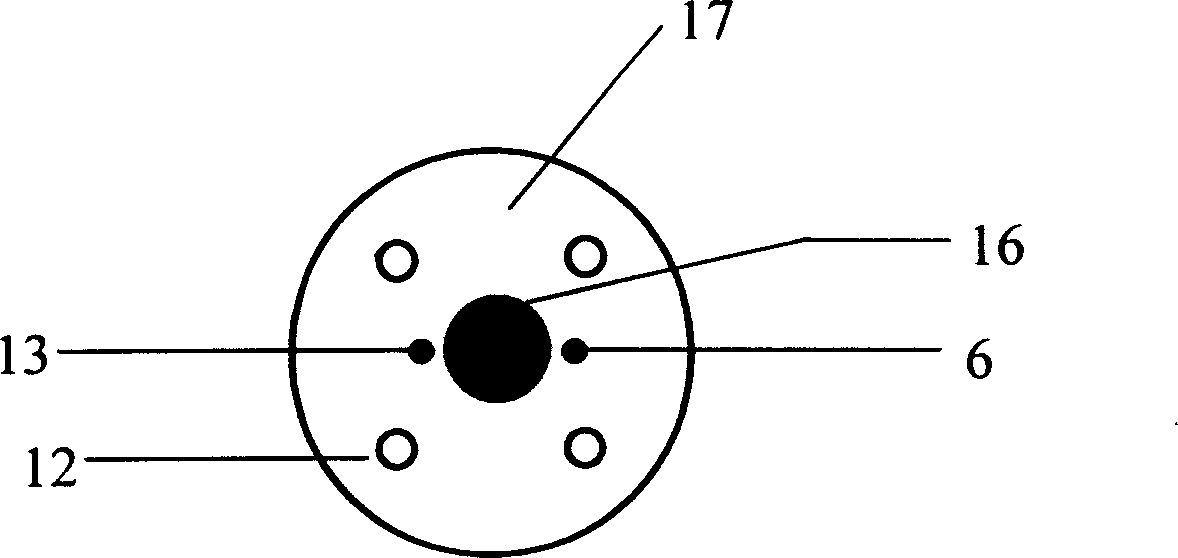

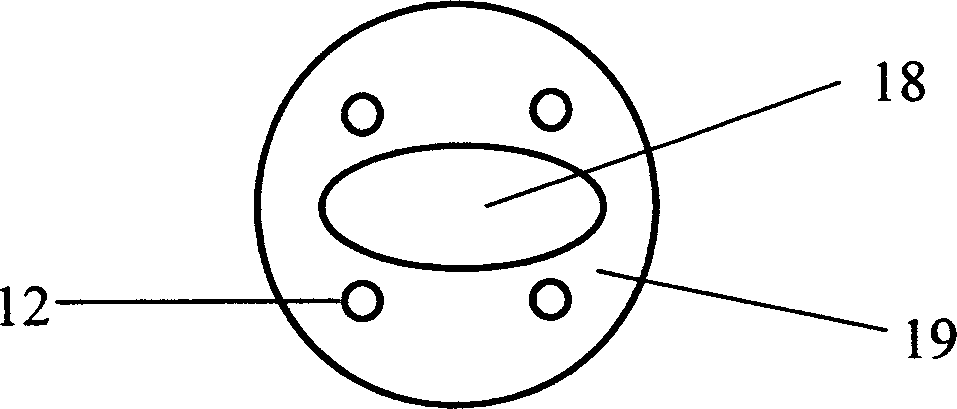

[0031] Example 1 Preparation method of the glucose sensor of the present invention for detecting glucose content.

[0032] First use the inverse microemulsion method, mix 7.5mL cyclohexane, 1.8mL n-hexanol and 1.77mL polyethylene glycol octylphenyl ether (OP) and stir for 30min, the surfactant OP can be replaced by TritonX-100, etc. The molar ratio of water to surfactant (W=10) was maintained. Then slowly add 400 μL 1×10 -2 mol L -1 The neutral red aqueous solution was uniformly stirred and reacted at room temperature for 30 minutes to form a stable water-in-oil system. Then slowly add 60-100 μL tetraethyl orthosilicate (TEOS) and 30-60 μL ammonia water (NH 3 ·H 2 O), at room temperature, continue to fully stir the reaction for 24h. The molar ratio of water to TEOS (W=10) was maintained. In the process of core-shell nanoparticles synthesized by water-in-oil microemulsion, under the catalysis of ammonia water, TEOS is gradually hydrolyzed and polycondensed to form a silic...

Embodiment 2

[0039] Example 2 The preparation method of the sensor for detecting lactic acid.

[0040] In the preparation of NR-SiO 2 For nanoparticles, change 1×10 -2 mol L -1 The amount of the neutral red aqueous solution is 300 μ L, and other preparation and treatment process are the same as embodiment 1. Characterized by TEM, the NR-SiO at this time 2 The particle size is 20±4nm (see Figure 5 ).

[0041] Bioactive enzymes and BSA and glutaraldehyde cross-linking method, except that 10 mg BSA and 0.4 mg LOD were dissolved in 100 μL of 0.1 mol L -1 (pH 6.9) in the phosphate buffered solution that is formulated as enzyme solution is different from embodiment 1, all the other preparation steps are identical with embodiment 1. The modification process is also the same as in Example 1.

[0042] After testing, the NR-SiO 2 The current response value of the nano-modified biosensor to lactic acid was 2.3 times that of the sensor prepared without nano-modification under the same conditi...

Embodiment 3

[0043] Example 3 Preparation of L-glutamic acid sensor

[0044] In the preparation of NR-SiO 2 For nanoparticles, the stirring reaction time was changed to 12h, and other preparation and treatment processes were the same as in Example 1. Characterized by TEM, the NR-SiO at this time 2 The particle size is 40±5nm.

[0045] Bioactive enzymes and BSA and glutaraldehyde cross-linking process, except that 10mg BSA and 0.2mg L-GOD were dissolved in 100μL 0.1mol L -1 (pH 6.9) in the phosphate buffer solution, is mixed with enzyme solution, is different from embodiment 1, and all the other processes are all the same as embodiment 1. After testing, the NR-SiO 2 The current response value of the nano-modified bioarray sensor to glutamate was 8.3 times that of the sensor prepared without nano-modification under the same conditions. After testing, the linear range of the sensor is 5.0×10 -7 ~1.0×10 -2 mol L -1 , the lowest detection limit of 2.0×10 -7 mol L -1 , and the correlat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com