Process of preparing ZSM-5 molecular sieve of nano size and containing hetero atom

A nano-sized, ZSM-5 technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of high toxicity of template agents, non-nano-sized, single synthesis conditions, etc. , to achieve the effect of controllable grain size, large crystallinity and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

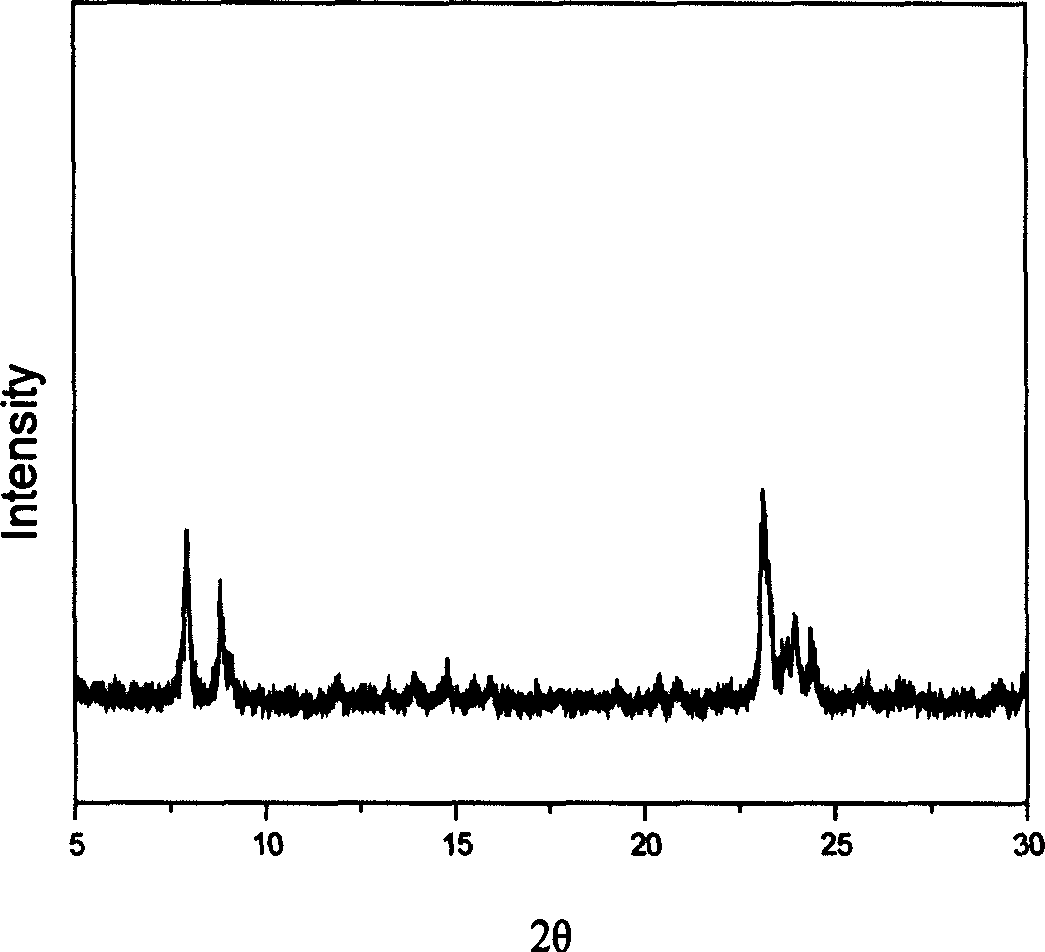

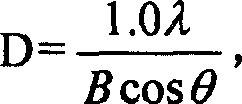

Embodiment 1

[0014] Mix the required amount of sodium hydroxide, sodium chloride, distilled water, aluminum sulfate and 22% tetrapropylammonium hydroxide solution evenly at room temperature, stir for 15 minutes and the mixed solution becomes clear, then add the required amount of concentration Add 25% silica sol dropwise to the above solution, stir for 30 minutes, put the above solution into a stainless steel reaction kettle, seal it and move it into an oven for static crystallization for 6 days, the crystallization temperature is 120°C. The relative molar content of each component in the reaction gel is: SiO 2 / Al 2 o 3 =65, NaOH / Al 2 o 3 =14, NaCl / Al 2 o 3 =130,H 2 O / Al 2 o 3 =2000,TPAOH / Al 2 o 3 =6, the product was suction filtered, washed, and dried at 120°C to obtain nanometer-sized ZSM-5 molecular sieves. The product is determined by XRD diffraction to be an MFI molecular sieve with a relative crystallinity of 90%, an average grain size of 40nm, and a specific surface area...

Embodiment 2

[0016] Mix the required amount of sodium hydroxide, sodium citrate, distilled water, sodium metaaluminate and 22% tetrapropylammonium hydroxide solution evenly at room temperature, stir for 15 minutes and the mixed solution becomes clear, then add the required amount Add white carbon black with a concentration of 85% dropwise to the above solution, stir for 30 minutes, put the above solution into a stainless steel reaction kettle, seal it and move it into an oven for static crystallization for 10 days, the crystallization temperature is 80°C . The relative molar content of each component in the reaction gel is: SiO 2 / Al 2 o 3 =85, NaOH / Al 2 o 3 =24, Na 3 C 6 h 5 o 7 / Al 2 o 3 =40,H 2 O / Al 2 o 3 =4000,TPAOH / Al 2 o 3 =15, the product was suction filtered, washed, and dried at 120°C to obtain nanometer-sized ZSM-5 molecular sieves. The product is determined by XRD diffraction to be an MFI structure molecular sieve, with a relative crystallinity of 90%, an average...

Embodiment 3

[0018] Mix the required amount of sodium hydroxide, sodium carbonate, distilled water, aluminum sulfate and tetrapropylammonium bromide uniformly at room temperature, and after stirring for 15 minutes, the mixed solution becomes clear, and then add the required amount of white carbon black with a concentration of 25%. Add it dropwise to the above solution, stir for 30 minutes, then put the above solution into a stainless steel stirring reaction kettle, seal it, stir and crystallize for 3 days, and the crystallization temperature is 110°C. The relative molar content of each component in the reaction gel is: SiO 2 / Al 2 o 3 =85, NaOH / Al 2 o 3 = 4, Na 2 CO 3 / Al 2 o 3 =55,H 2 O / Al 2 o 3 =10000, TPABr / Al 2 o 3 =20, the product was suction filtered, washed, and dried at 120°C to obtain nanometer-sized ZSM-5 molecular sieves. The product is determined by XRD diffraction to be an MFI molecular sieve with a relative crystallinity of 97%, an average grain size of 60nm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com