Bismuth oxide micro-powder and its preparation method

A bismuth oxide and micropowder technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve problems affecting product quality, bismuth oxide recovery loss, environmental pollution, etc., achieve stable and controllable dissolution process, and short dissolution rate , the effect of low residual acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

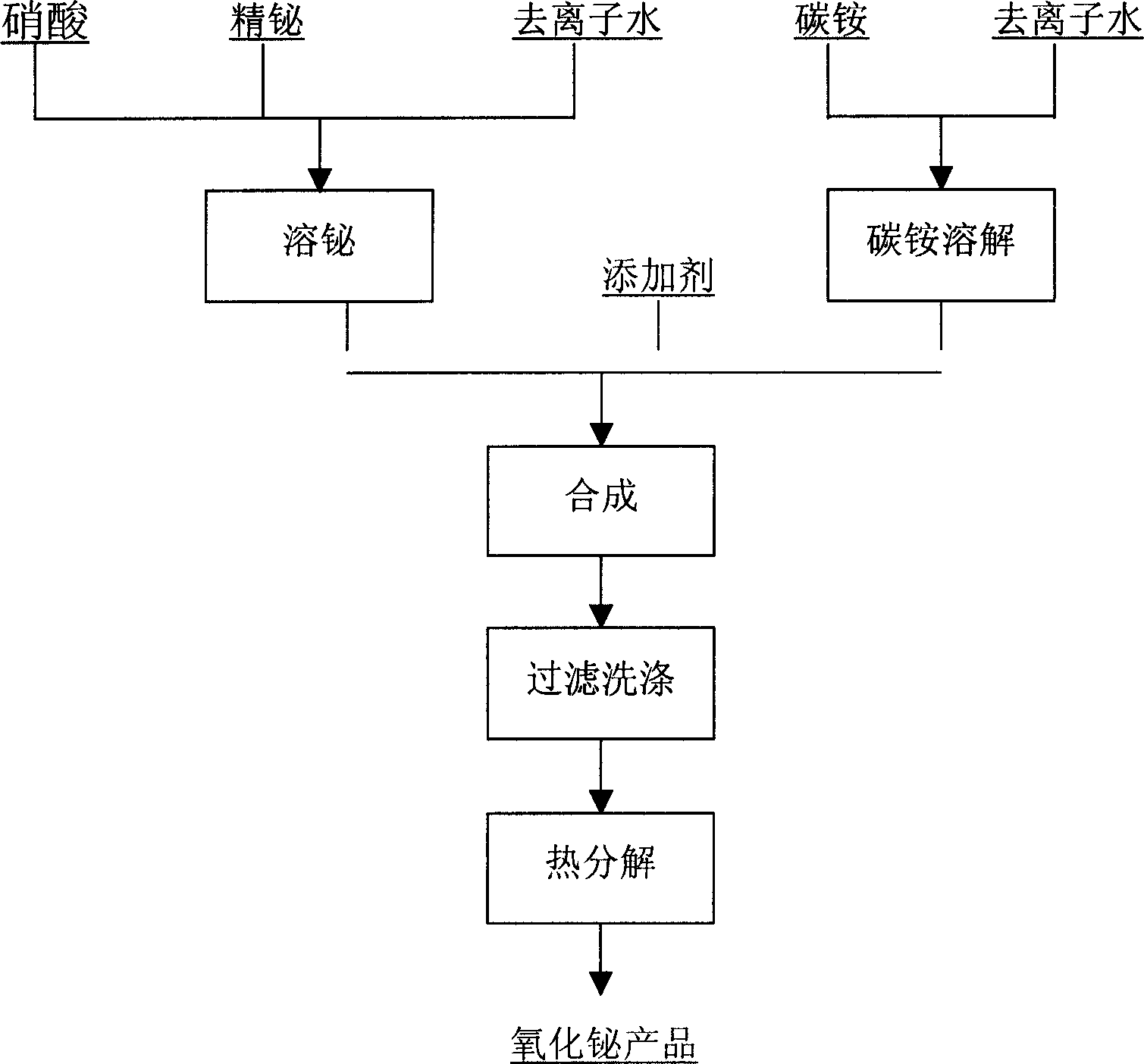

Method used

Image

Examples

Embodiment 1

[0040] Soak 300g of bismuth metal in 300mL of deionized water, slowly add 450mL of 65wt% nitric acid to dissolve under stirring; add 150g of ammonium bismuth into 600mL of deionized water to prepare a 20wt% solution;

[0041] Under room temperature and stirring, add 3mL isopropanol to the ammonium bicarbonate solution, then add bismuth nitrate solution at a rate of 300mL / min, the solution gradually turns into a milky white precipitate, and calcined at 600°C to obtain 1μm light yellow High-purity bismuth oxide powder. The technical indicators are shown in Table 1.

[0042] product name

Embodiment 2

[0044] Soak 300g of bismuth metal in 300mL of deionized water, slowly add 450mL of 65wt% nitric acid to dissolve under stirring; add 150g of ammonium bismuth into 600mL of deionized water to prepare a 20wt% solution;

[0045] Under room temperature and stirring, add bismuth nitrate solution to ammonium bicarbonate solution at a rate of 75mL / min, the solution gradually turns into a milky white precipitate, and calcined at 600°C to obtain 5 μm light yellow high-purity bismuth oxide powder. The technical indicators are shown in Table 2.

[0046] product name

Embodiment 3

[0048] Soak 300g of bismuth metal in 300mL of deionized water, slowly add 450mL of 65wt% nitric acid to dissolve under stirring; add 150g of ammonium bismuth into 600mL of deionized water to prepare a 20wt% solution;

[0049] Under room temperature and stirring, add bismuth nitrate solution to ammonium bicarbonate solution at a speed of 10mL / min, the solution gradually turns into a milky white precipitate, and calcined at 600°C to obtain 50μm light yellow high-purity bismuth oxide powder. The technical indicators are shown in Table 3.

[0050] product name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com