Method for preparing novel B level high speed polyurethane enamelled wire paint

A technology of polyurethane varnish and wire varnish, which is applied in polyurea/polyurethane coating, cable/conductor manufacturing, electrical components, etc., and can solve problems such as uneven enameled wire surface and poor thermal shock performance, unstable batch quality of enameled wire varnish, enameled wire Avoid problems such as poor storage stability of paint, achieve the effect of promoting the reaction to proceed smoothly, stabilizing product quality, and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

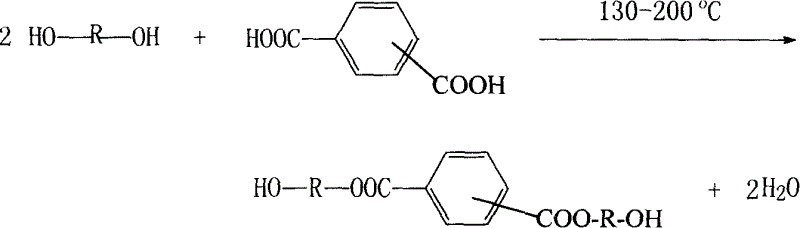

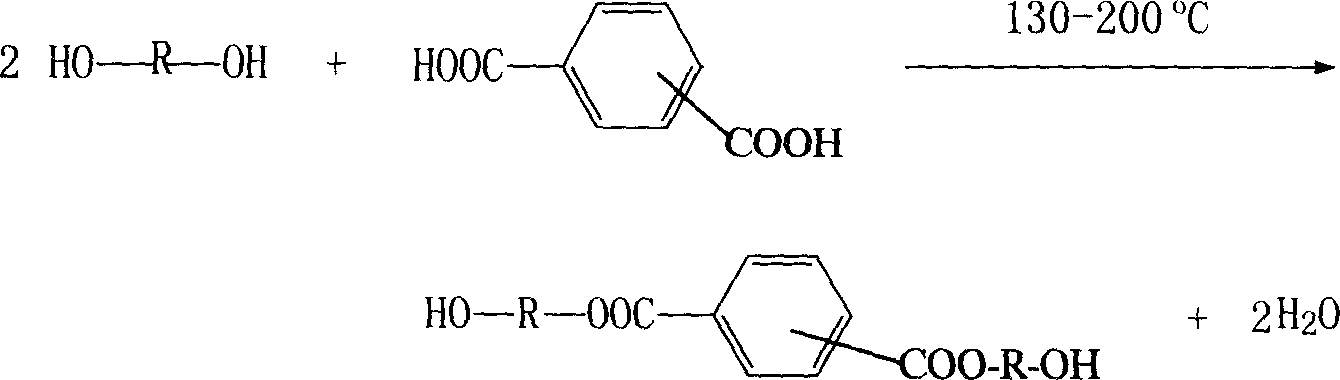

[0068] Step 1, the preparation of disubstituted aromatic dihydric alcohols:

[0069] 34 kg of terephthalic acid, 69 kg of neopentyl glycol, and 0.16 kg of organic titanium-antimony composite catalyst are reacted at 130°C-150°C for about 3 hours to produce 92-95 kg of disubstituted aromatic diols. Aromatic dihydric alcohol is a colorless transparent solution above the melting point, its melting point is 45°C-50°C, its hydroxyl value is 550, and its acid value is 2.7.

[0070] Step 2, the synthesis of hydroxyl component:

[0071] Add 47 kg of disubstituted aromatic diols, 94 kg of phthalic anhydride, 25 kg of adipic acid, 50 kg of glycerin, 150 kg of neopentyl glycol, 0.6 kg of organic titanium-antimony composite catalyst and 10 kg of xylene into the reactor. Start the heating device, react at 140°C to 180°C for 2 hours; then raise the temperature to 190°C and maintain it for 2 hours; then react at 195°C-200°C for 1 hour; start vacuuming, maintain 190°C, 0.05MPa~ 0.1MPa, unti...

Embodiment 2

[0077] Step 1, preparation of disubstituted aromatic dihydric alcohols

[0078]22 kg of terephthalic acid, 99 kg of neopentyl glycol, and 0.24 kg of organotitanium-antimony composite catalyst are reacted at 130°C-150°C for about 3 hours to produce 114-115 kg of disubstituted aromatic diols. Aromatic dihydric alcohol is a colorless transparent solution above the melting point, its melting point is 42°C-46°C, its hydroxyl value is 750, and its acid value is 1.6.

[0079] Step 2, the synthesis of hydroxyl components

[0080] Mix 50 kg of disubstituted aromatic diols, 250 kg of phthalic anhydride, 70 kg of adipic acid, 150 kg of 1,1,1-trimethylolpropane, 200 kg of neopentyl glycol, and compound organic titanium-antimony Catalyst 4 kilograms and 60 kilograms of xylenes are added in the reactor successively. Start the heating device, react at 140°C to 180°C for 2 hours; then raise the temperature to 190°C and maintain it for 2 hours; then react at 195°C-200°C for 1 hour; start vac...

Embodiment 3

[0086] Step 1, preparation of disubstituted aromatic dihydric alcohols

[0087] 10 kg of terephthalic acid, 45 kg of 2-methyl-1, 3-propanediol, and 0.15 kg of organic titanium-antimony composite catalyst are reacted at 130°C-150°C for about 3 hours to produce disubstituted aromatic diol 47 ~48 kg, the disubstituted aromatic dihydric alcohol is a colorless transparent solution above the melting point, the melting point is 40°C-45°C, the hydroxyl value is 760, and the acid value is 1.7.

[0088] Step 2, the synthesis of hydroxyl components

[0089] 40 kg of disubstituted aromatic diols, 160 kg of phthalic anhydride, 40 kg of adipic acid, 80 kg of 1,1,1-trimethylolpropane, 160 kg of 2-methyl-1,3-propanediol 1.5 kg of organotitanium-antimony composite catalyst and 35 kg of xylene were added to the reaction kettle in sequence. Start the heating device, react at 140°C to 180°C for 2 hours; then raise the temperature to 190°C and maintain it for 2 hours; then react at 195°C-200°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com