Glyconitroso ferrohemoglobin pigment, it preparation and application

A technology for sylation of nitroso-hemoglobin, applied in the field of glycosylated nitroso-hemoglobin pigment and its preparation and application, to achieve the effects of improved storage stability, good dispersibility, and light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Collect fresh pig blood qualified for quarantine, add 0.5% sodium citrate for anticoagulation, centrifuge at 3000r / min for 15min, discard the upper serum, add an equal volume of normal saline (0.9%NaCL) to wash the red blood cells, and centrifuge again at the same speed After 15 minutes, red blood cells were collected. Add an equal volume or three times the volume of distilled water, stir for 30 minutes, and then swell and break the wall to release hemoglobin.

[0031] Add 0.1% sodium erythorbate and 0.05% sodium nitrite to the hemoglobin solution, adjust the pH to 5.9, and marinate at 4°C for 24 hours to obtain a nitrosohemoglobin solution.

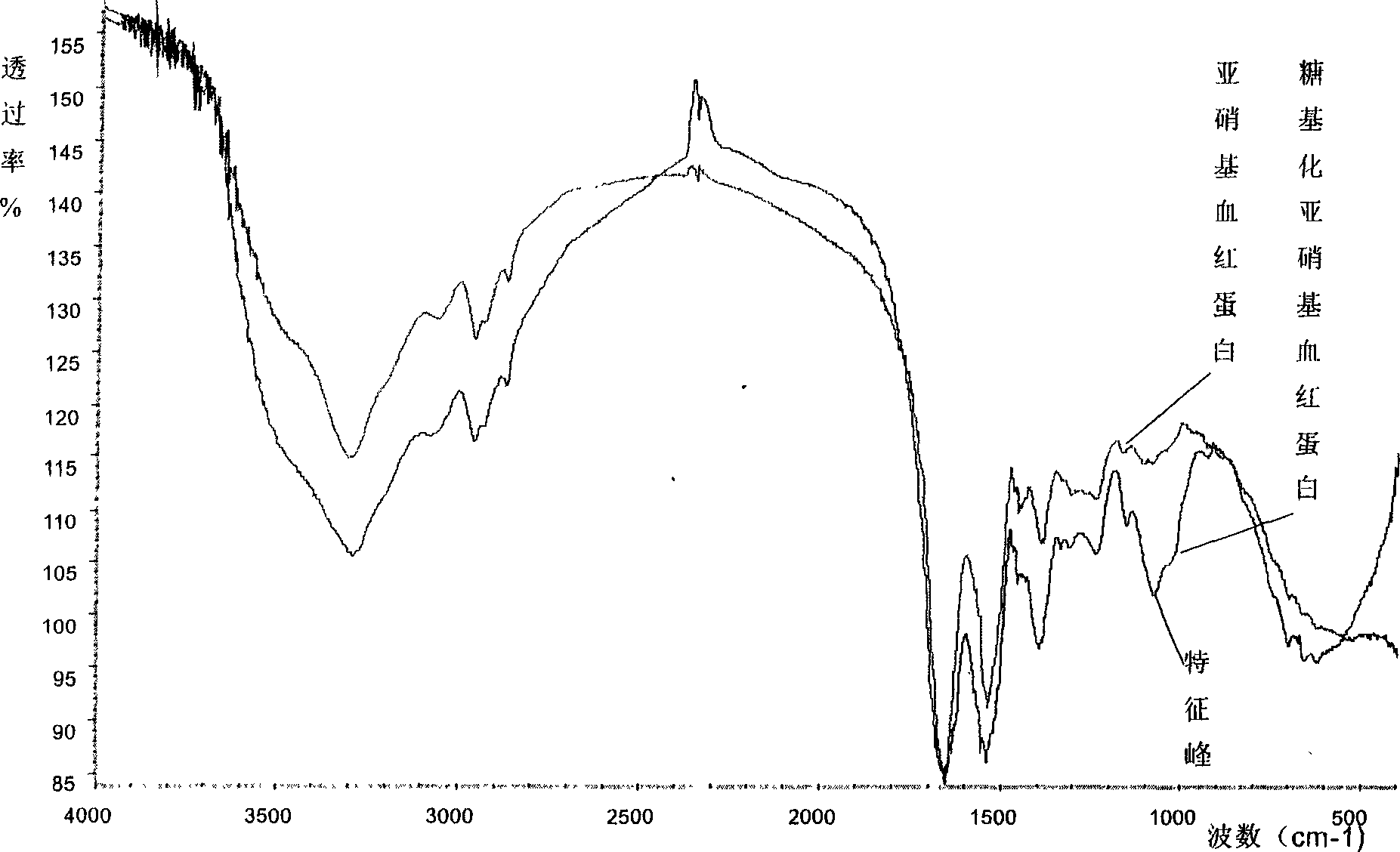

[0032] Nitrosohemoglobin is mixed with 1% chitosan solution (dissolved in 1% acetic acid solution) of equal volume, the concentration of nitrosohemoglobin in the reaction solution is 5%, the concentration of sugar is 0.5%, and the pH adjustment is 4.5, Then heated at 50°C for 20 minutes, and filtered to obtain glycosylated nitros...

Embodiment 2

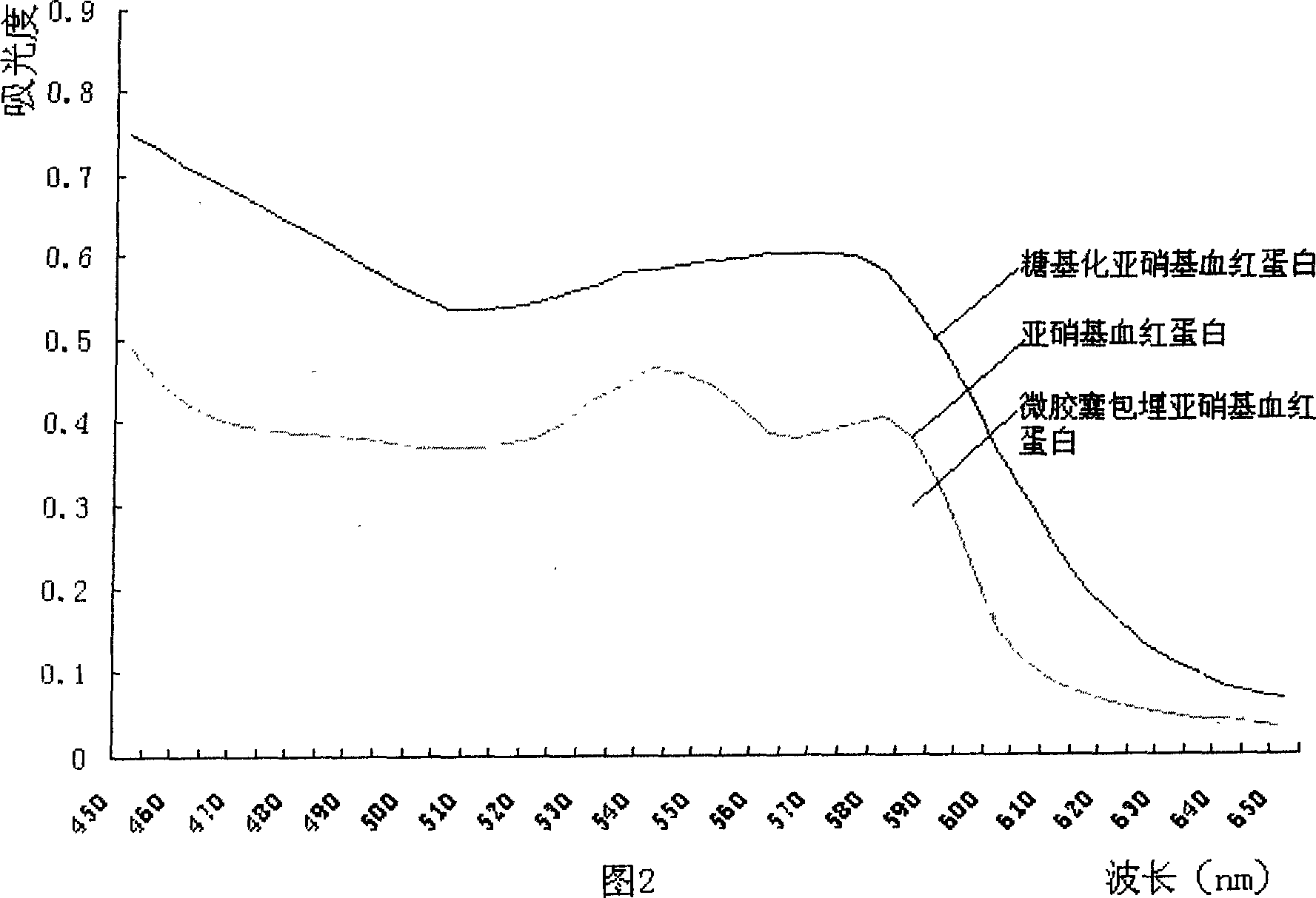

[0035] The sugar solution used is an equal-volume mixed solution of 2% chitosan (dissolved in 1% acetic acid) and 2% glucose, the nitrosohemoglobin is mixed with the mixed sugar solution in equal volume, and the concentration of the nitrosohemoglobin in the reaction solution is 6%, the concentration of sugar is 1%, adjust the pH to be 6.0, heat 5min at 70°C, all the other operating conditions are the same as in Example 1, the sugar content in the obtained powdery pigment is 18%; its ultraviolet absorption is different from that of microcapsules Buried nitrosohemoglobin, a mixture of nitrosohemoglobin and carbohydrates. After heating at 85°C for 10 minutes, the glycosylated nitrosohemoglobin pigment solution is still a red liquid, while the microcapsule-embedded pigment has denatured and precipitated. Experiments show that the thermal stability of the glycosylated pigment is significantly improved.

Embodiment 3

[0037] Mix 2 volumes of hemoglobin solution with 1 volume of 2% chitosan solution, so that the concentration of nitrosohemoglobin in the reaction solution is 8%, the content of sugar is 0.7%, adjust the pH to 7.5, and heat at 40°C for 50min. All the other operating conditions are the same as in Example 1, and the sugar content in the obtained powdery pigment is 8%, which is lower than the product embedded in microcapsules.

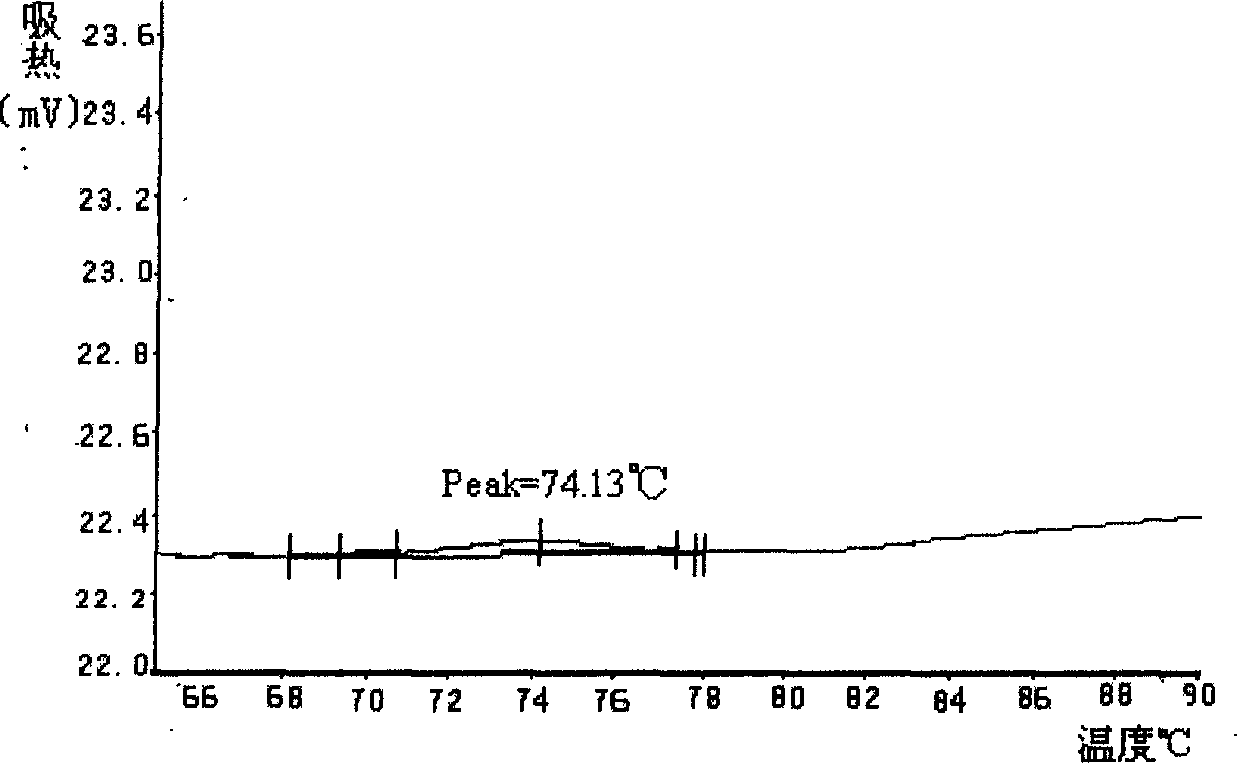

[0038] Measured by differential scanning calorimetry (DSC), the thermal denaturation temperature of nitrosohemoglobin is 74.13°C, and the thermal denaturation temperature of glycosylated nitrosohemoglobin increases from 74.13°C to 97.69°C through glycosylation treatment of proteins. However, the thermal denaturation temperature of the nitrosohemoglobin pigment embedded in microcapsules was 79.19°C, indicating that the thermal stability of the glycosylated nitrosohemoglobin pigment was significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com