Hemostatic material of new type pore-borne molecular sieve and preparation method

A technology of mesoporous molecular sieves and hemostatic materials, applied in the field of mesoporous molecular sieve hemostatic materials and their preparation, to achieve the effects of cheap and easy-to-obtain raw materials, mild reaction conditions, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

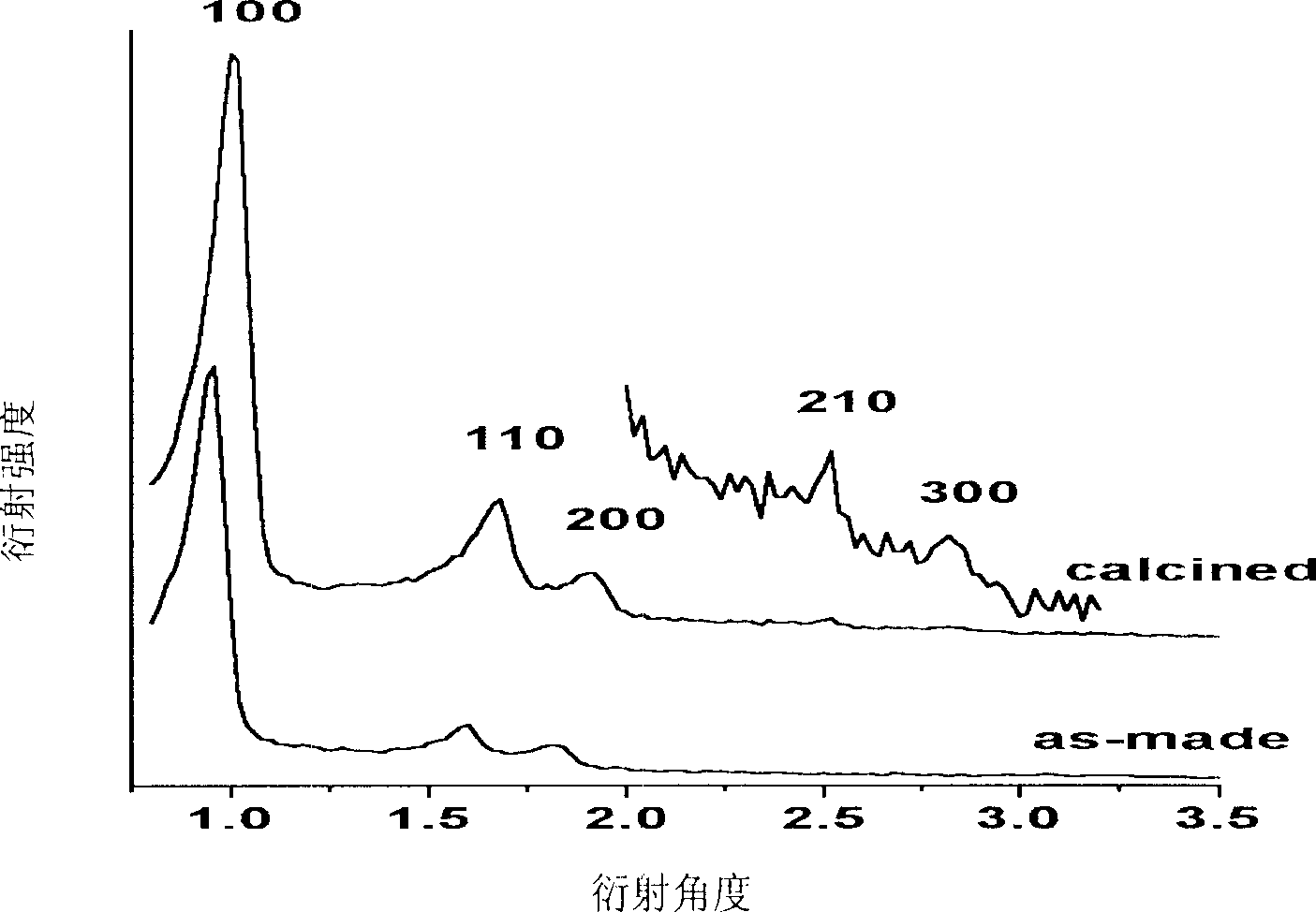

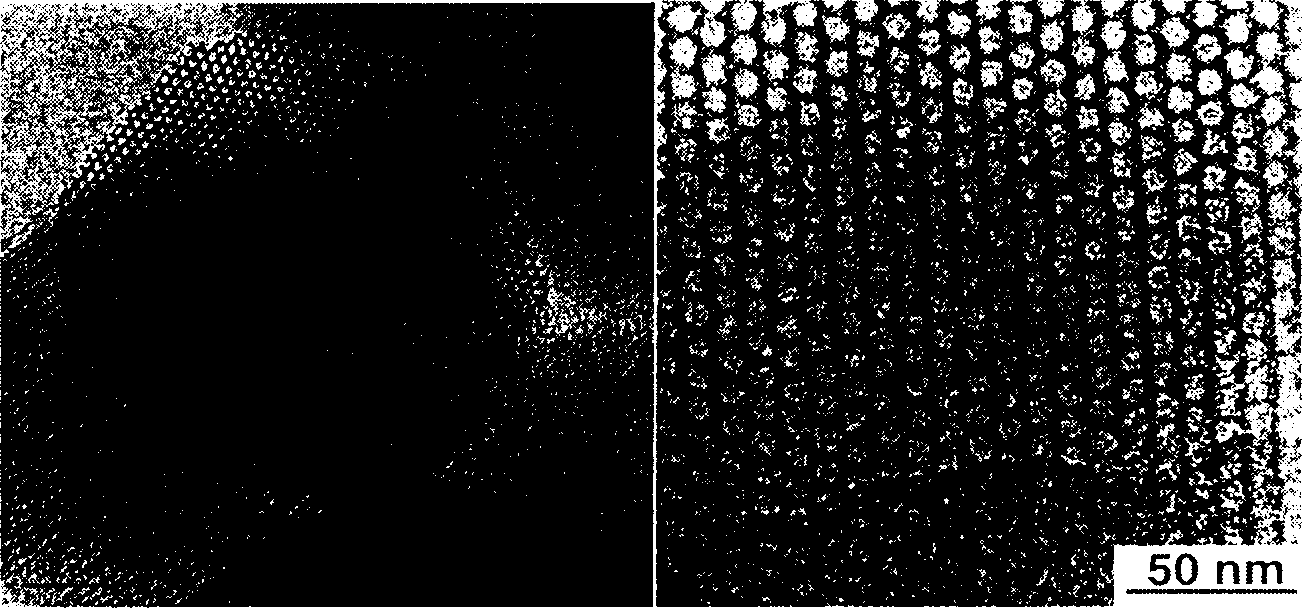

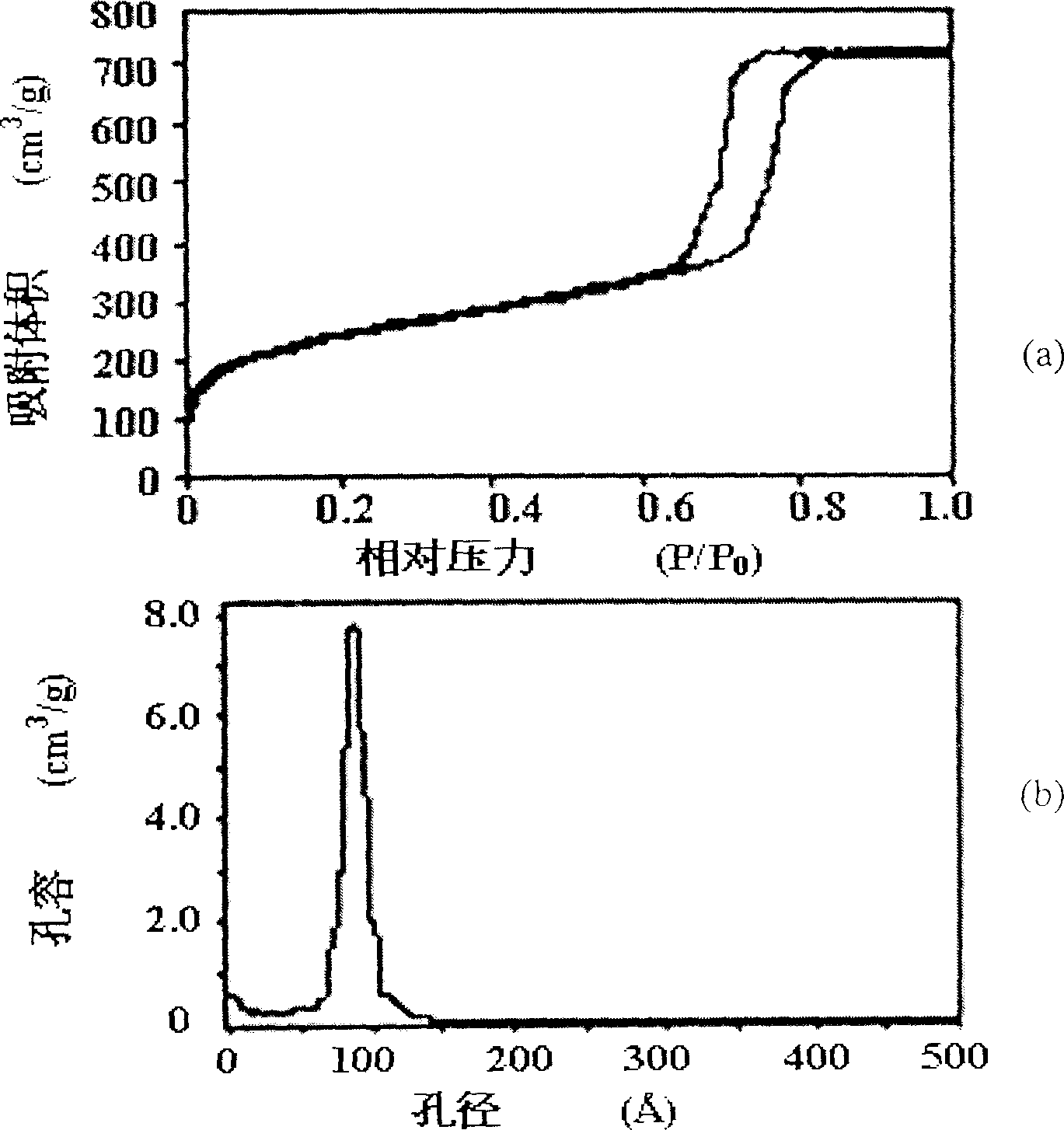

Embodiment 1

[0037] 2.08g (10mmol) TEOS was dissolved in 10g ethanol, 0.5g water and 0.4g 0.1M HCl were added to the solution, stirred at room temperature for 1 hour, mixed evenly and then mixed with 0.9g triblock copolymer surfactant P123 (EO 20 PO 70 EO 20 ), stirred at room temperature for 1 hour and mixed with ethanol solution. Transfer the above-mentioned clear solution to a large petri dish, and remove the solution ethanol by natural volatilization (complete drying, generally takes 1 day), and a colorless, transparent and soft thick film is obtained. After the film was separated from the bottom of the petri dish, put it into a 100ml polytetrafluoroethylene bottle, add about 70ml of water, and conduct a hydrothermal treatment in an oven at 100°C for 72 hours. A white opaque thick film was obtained, separated by suction filtration, dried at room temperature and calcined at 500°C for 6 hours to remove the surfactant, and a two-dimensional hexagonal phase (p6mm structure) pure silica ...

Embodiment 2

[0039] 0.40g EO at room temperature 39 BO 47 EO 39 (B50-6600) was dissolved in 30g of 0.5mol / L HCl solution, and 2.08g of TEOS was added to the resulting clear solution. The molar ratio of each reactant was TEOS / EO 39 BO 47 EO 39 / HCl / H 2 O=1:0.0074:6:166. After the reactant was stirred at room temperature for one day, it was hydrothermally heated at 100° C. for one day. The resulting white precipitate was filtered, washed three times with deionized water, and dried at room temperature. Baking at 550° C. in an air atmosphere for 6 hours to remove the template agent, the heating rate was controlled at 2° C. / min, and finally a three-dimensional cubic phase (Im3m structure) pure silica mesoporous molecular sieve powder material was obtained. Its coagulation effect is good.

Embodiment 3

[0041] 4.0g nonionic surfactant EO 20 PO 70 EO 20 (P123), 1.4g calcium nitrate (Ca(NO 3 ) 4 4H 2 O), 6.7g tetraethyl orthosilicate (TEOS) was dissolved in 60g ethanol, then added 1.0g 0.5M hydrochloric acid solution, stirred at room temperature for 24h, poured into a petri dish, and aged for about 72h to make the hydrolysis-polycondensation reaction fully Proceed to form a gel and place the gel in a desiccator. The gel block obtained after drying is calcined at 700° C. for 5 hours in a muffle furnace to obtain a two-dimensional hexagonal phase (p6mm structure) silicon oxide mesoporous molecular sieve material containing calcium oxide. Its coagulation effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com