Method for fabricating transistor of aluminum-gallium-nitrogen/gallium nitride with high electron mobility

A technology with high electron mobility and fabrication method, which is applied in the fabrication field of aluminum gallium nitride/gallium nitride high electron mobility transistors, and can solve the problem of less two-dimensional electron gas in the channel and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

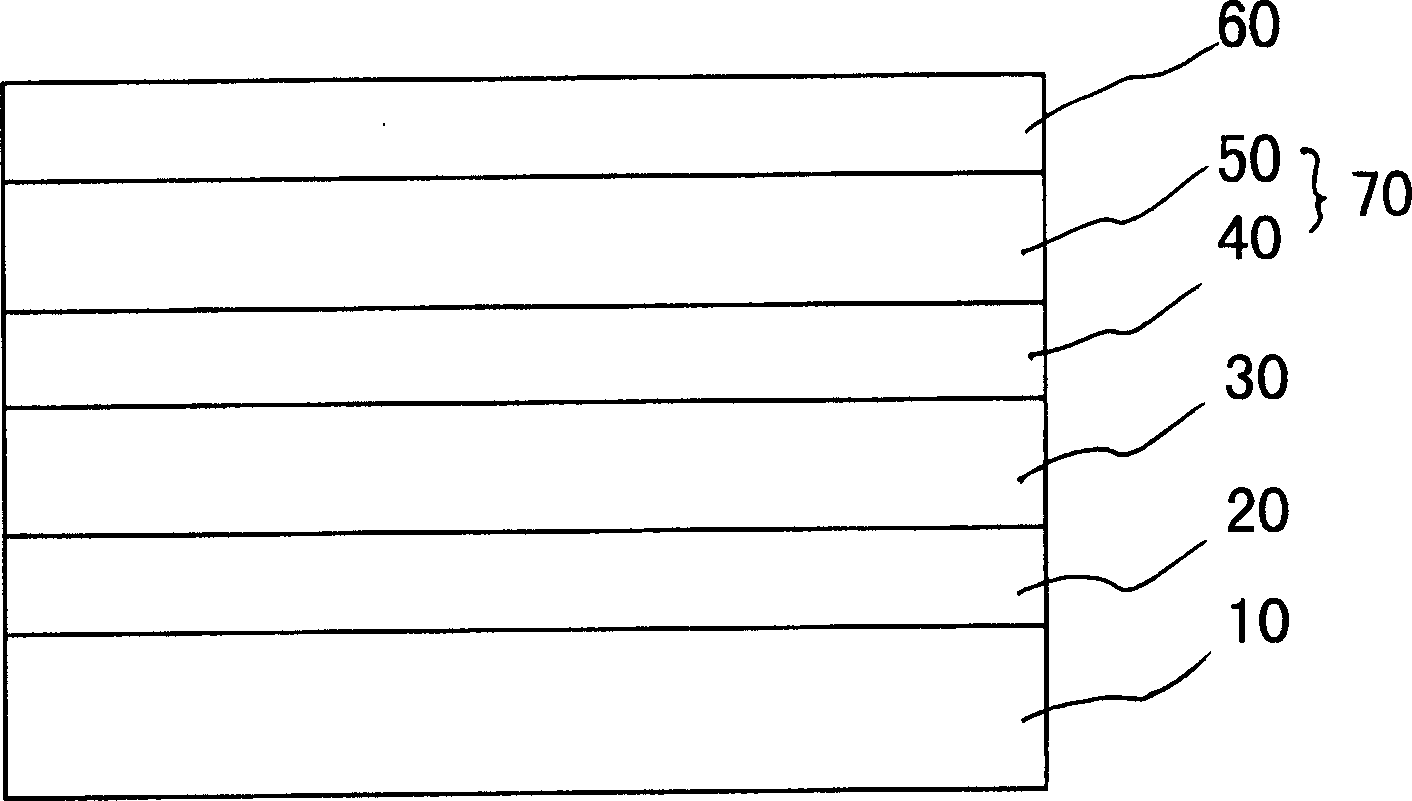

[0027] see again figure 1 Firstly, a layer of aluminum nitride nucleation layer 20 is grown on the substrate sapphire (0001) 10 crystal surface by molecular beam epitaxy technology, the substrate temperature is about 600-700° C., and the growth thickness is about 0.2 nm.

[0028] A thick non-intentionally doped semi-insulating GaN buffer layer 30 was grown on the AlN nucleation layer 20 at a substrate temperature of about 800° C., a nitrogen flow rate of 1.2 sccm, an RF power of 400 W, and a growth thickness of 2 μm.

[0029] A barrier layer 70 with high Al content is grown on the gallium nitride buffer layer 30, including an unintentionally doped space isolation layer 40 and an n-type doped carrier supply layer 50, and the growth thicknesses are 3nm and 21nm respectively, Al The content of Si is 43.2%, and the doping concentration of Si in the carrier supply layer is 2×10 -18 cm -3 .

[0030] Finally, a GaN capping layer 60 is grown with a thickness of 1 nm.

[0031] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com