Method for lixiviating effective components from biomass material

A technology for biomass materials and active ingredients, applied in the field of extracting their active ingredients, can solve the problems of loss of volatile components, long extraction time, and high energy consumption, and achieve the effects of improving extraction rate, short extraction time, and small temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

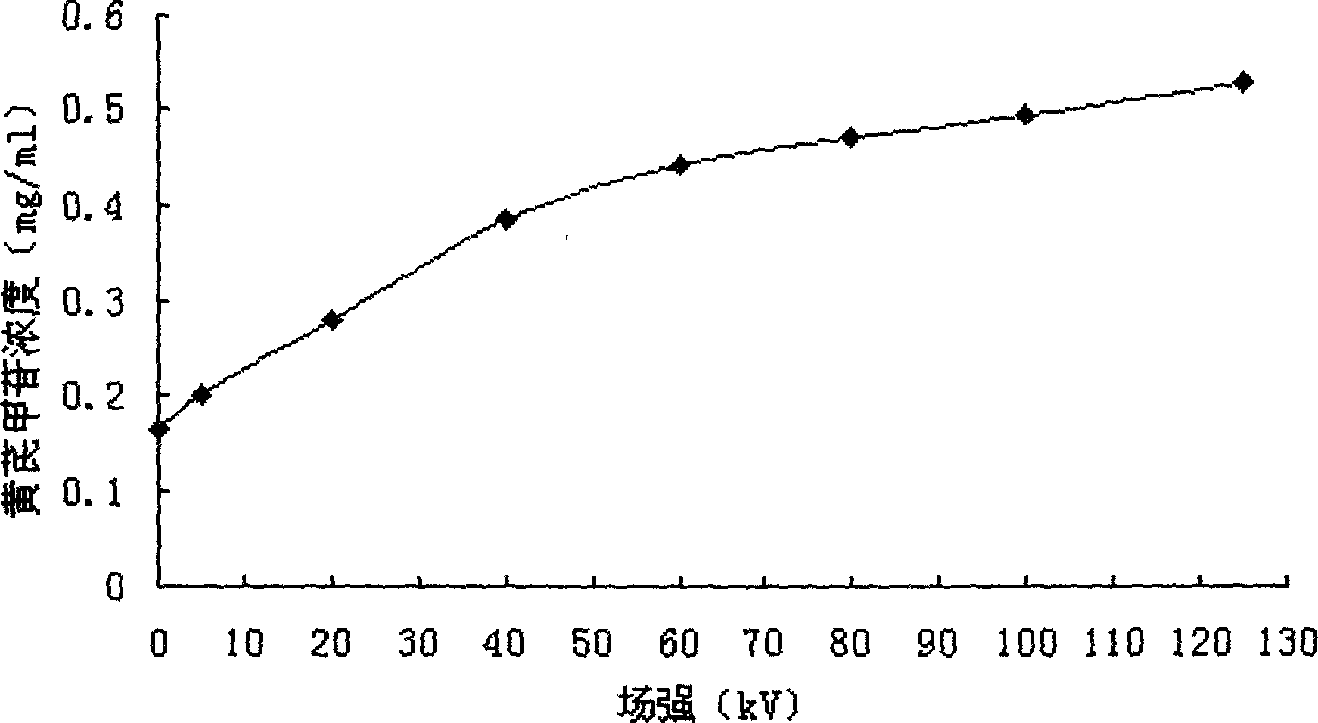

[0021] Taking the extraction of astragaloside IV as an example, the influence of the field strength of the high-voltage pulsed electric field on the extraction is described in detail.

[0022] After astragalus is crushed, it is added into 50% ethanol solution to form a mixed solution with a ratio of solid to liquid of 1:200. Divide this test into 8 groups, and the test labels are A1, A2, A3, A4, A5, A6, A7, A8. The above 8 groups of samples except No. A1 sample were leached according to the current conventional process, and the other 7 groups of samples were respectively treated by high-voltage pulse electric field. The treatment conditions are as follows:

[0023] A2: Field strength 5kV / cm, 1 pulse; A3: Field strength 20kV / cm, 1 pulse; A4: Field strength 40kV / cm, 1 pulse; A5: Field strength 60kV / cm, 1 pulse; A6: Field strength 80kV / cm, 1 pulse; A7: field strength 100kV / cm, 1 pulse; A8: field strength 125kV / cm, 1 pulse.

[0024] Centrifuge the material treated by the high-vo...

Embodiment 2

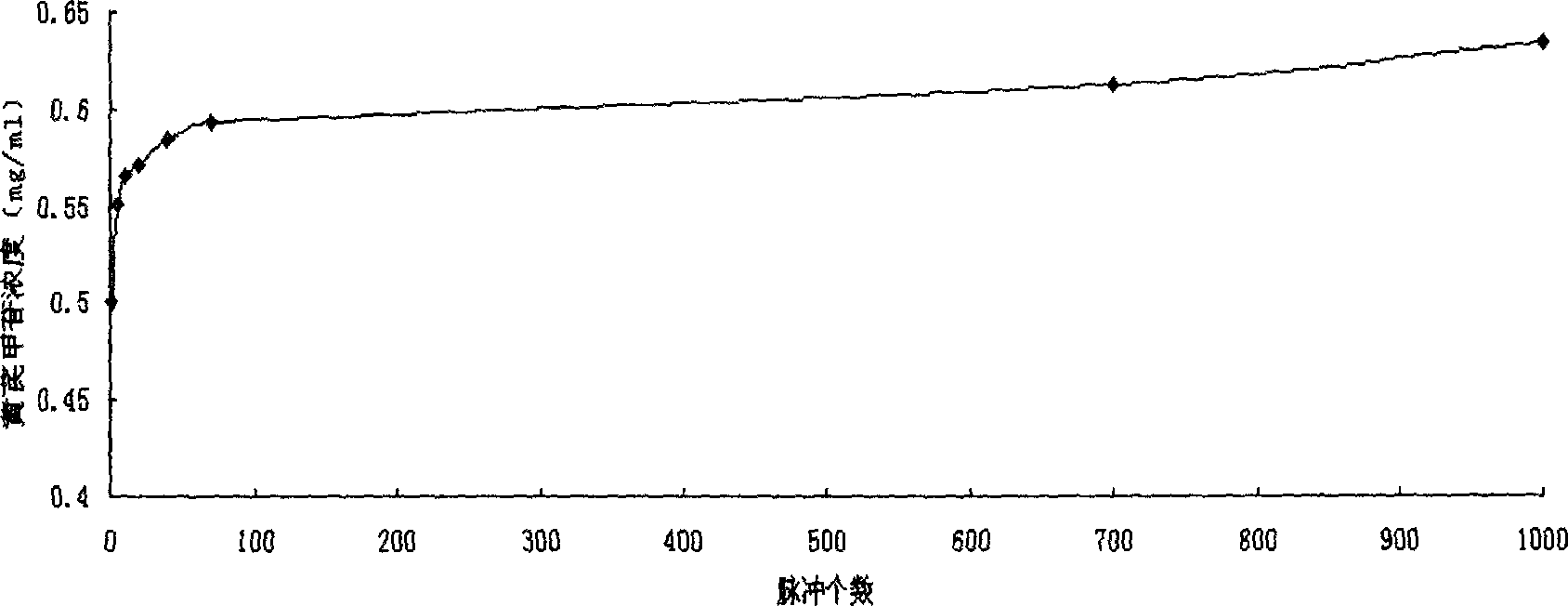

[0027] Taking the extraction of astragaloside IV as an example, the influence of the number of high-voltage pulsed electric field pulses on the extraction is described in detail.

[0028] After astragalus is crushed, it is added into 50% ethanol solution to form a mixed solution with a ratio of solid to liquid of 1:200. Divide this test into 8 groups, the test labels are B1, B2, B3, B4, B5, B6, B7, B8. The above 8 samples were respectively treated by high-voltage pulsed electric field, and the treatment conditions were as follows:

[0029] B1: 1 pulse, field strength 80kV / cm; B2: 5 pulses, field strength 80kV / cm; B3: 10 pulses, field strength 80kV / cm; B4: 20 pulses, field strength 80kV / cm; B5: 40 pulses, field strength 80kV / cm; B6: 70 pulses, field strength 80kV / cm; B7: 700 pulses, field strength 80kV / cm; B8: 1000 pulses, field strength 80kV / cm.

[0030] Centrifuge the material treated by the high-voltage pulse electric field, take the supernatant, and detect the content of ...

Embodiment 3

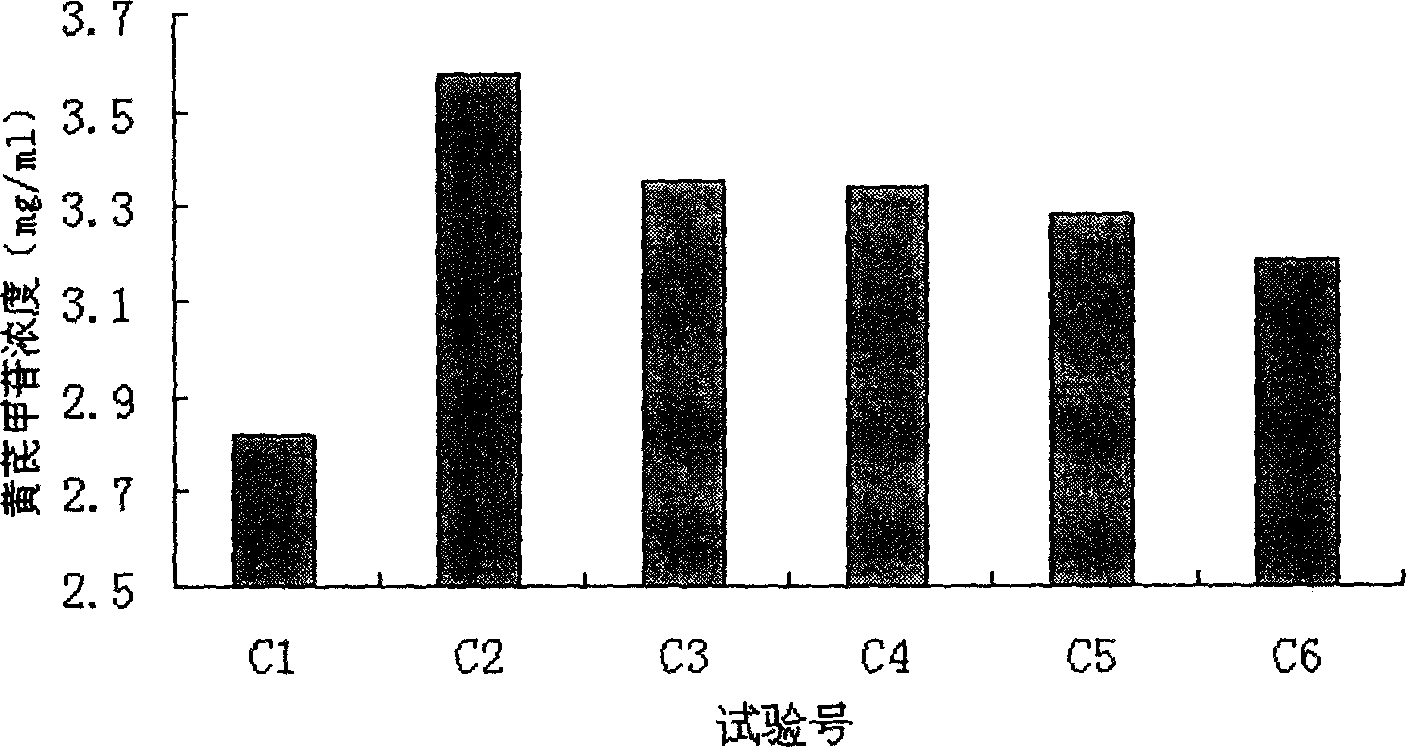

[0033] Taking the extraction of astragaloside IV as an example, the influence of different solvents on the extraction of high-voltage pulsed electric field is described in detail.

[0034] After astragalus is crushed, it is added to different solvents to prepare a solution with a solid-liquid ratio of 1:200. This test is divided into 6 groups, and the test labels are respectively C1, C2, C3, C4, C5 and C6. The above sample test conditions are as follows:

[0035] C1: solvent (distilled water), high voltage pulse electric field (100kV / cm, 10 pulses);

[0036] C2: solvent (sodium hydroxide solution with pH=14), high-voltage pulsed electric field (25kV / cm, 5 pulses);

[0037] C3: solvent (citric acid solution with pH=1), high-voltage pulsed electric field (25kV / cm, 5 pulses);

[0038] C4: solvent (50% ethanol aqueous solution), high voltage pulsed electric field (100 kV / cm, 10 pulses).

[0039] C5: solvent (50% methanol aqueous solution), high voltage pulse electric field (10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com