High-density bacterium culturing method and its biological reactor

A technology of cell culture and bioreactor, which is applied in the field of cell high-density circulation or continuous culture method and its bioreactor device, which can solve the problem of difficult to eliminate bacteria pollution, difficult circulation or continuous high-density culture, etc. problems, to achieve the effect of improving equipment utilization, shortening production cycle, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

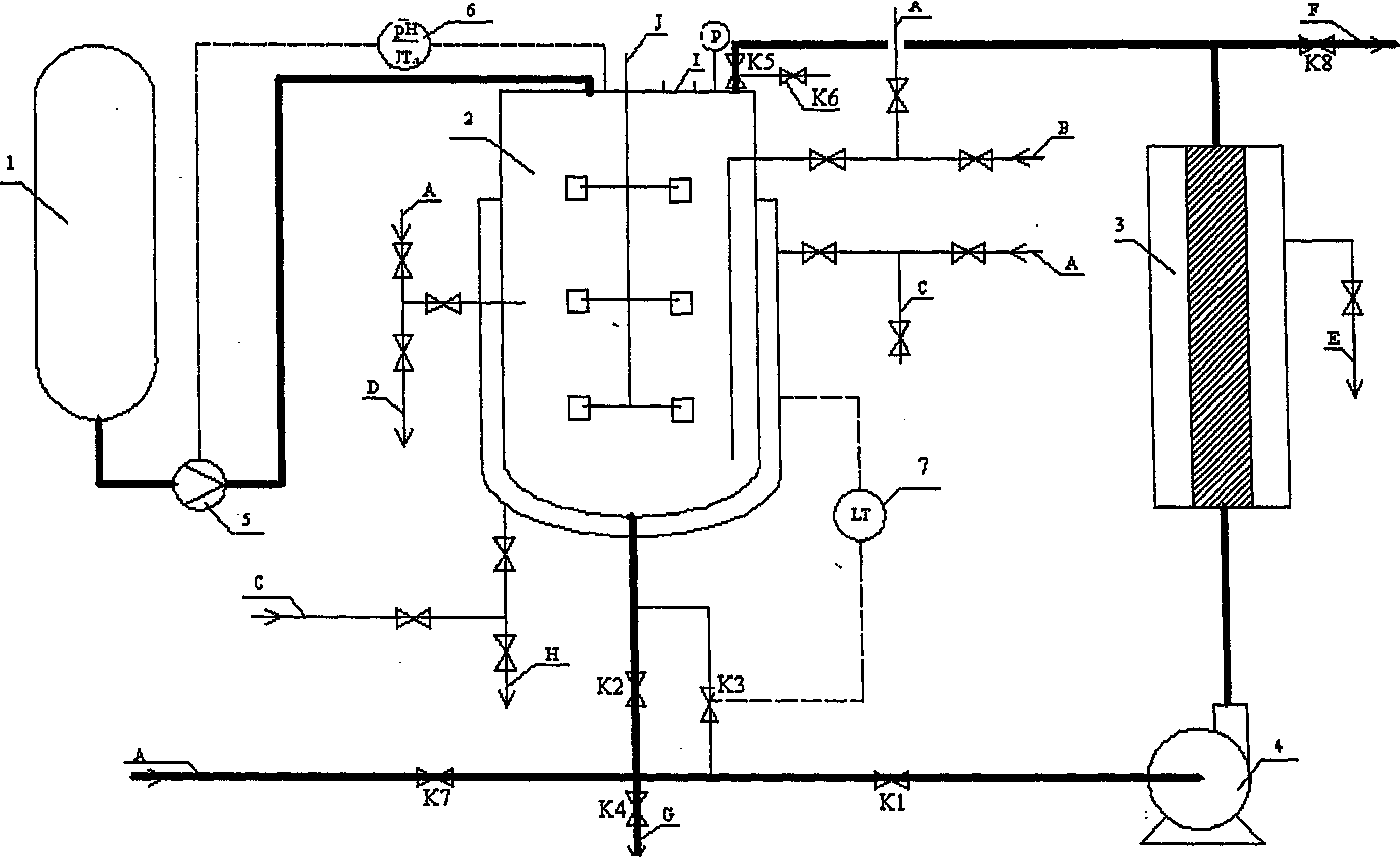

[0024] High-density culture of lactic acid bacteria circulation

[0025] First, add beef extract 1%, peptone 1%, yeast extract 1%, glucose 15%, Tween 80 0.05% pH6.5 medium in the cleaned bioreactor, and bioreactor 2 and tank with the conventional method The pipelines connected to the body are heat sterilized, and the seeds can be inserted into the seed solution after being cooled by the jacket cooling water and cultivated at 30 °C. Before the end of the cultivation, when K2K3K4 is closed, open K1K6K8 and use steam to sterilize the inorganic membrane module, pump 4 and the pipeline connected to it, then close K6K7K8 and cool down to room temperature properly. When the concentration of lactic acid bacteria in the bioreactor reaches 10 5 cfu / ml-10 8 When cfu / ml, turn on K2K1K5, turn on pump 4, circulate and filter through the membrane tube, discard the clear liquid through the clear liquid outlet, and return the concentrated bacterial liquid to the bioreactor. After circulating...

Embodiment 2

[0027] Continuous high-density culture of Escherichia coli

[0028] First, add lactose 0.5%, tryptone 2%, potassium dihydrogen phosphate 0.275%, dipotassium hydrogen phosphate 0.275%, NaCl 0.5%, sodium lauryl sulfate 0.05% pH6.6- 7.0 culture medium, heat-sterilize the bioreactor 2 and the pipeline connected with the tank according to the conventional method, and after cooling through the jacket cooling water, it can be connected to the seed liquid for cultivation under certain conditions. Before the end of the cultivation, when K2K3K4 is closed, open K1K6K8 and use steam to sterilize the inorganic membrane module, pump 4 and the pipeline connected to it, then close K6K7K8 and cool it down properly. When the concentration of E. coli in the bioreactor reaches 10 5 cfu / ml-10 8 When cfu / ml, turn on K2K1K5, turn on pump 4, circulate and filter through the membrane tube, discard the clear liquid through the clear liquid outlet, and return the concentrated bacterial liquid to the bi...

Embodiment 3

[0030] Continuous High Density Culture of Yeast

[0031] First, add wort juice (2%-12%) in the cleaned bioreactor, carry out thermal sterilization to bioreactor 2 and the pipeline that communicates with the tank body according to the conventional method, after cooling by jacket cooling water, It can be cultivated under certain conditions by accessing the seed solution. Before the end of the cultivation, when K2K3K4 is closed, open K1K6K8 and use steam to sterilize the inorganic membrane module, pump 4 and the pipeline connected to it, then close K6K7K8 and cool it properly. When the yeast concentration in the bioreactor reaches 10 5 cfu / ml-10 8 When cfu / ml, turn on K2K1K5, turn on pump 4, circulate and filter through the membrane tube, discard the clear liquid through the clear liquid outlet, and return the concentrated bacterial liquid to the bioreactor. After circulating and filtering, the bacterial cells in the bioreactor After the concentration is increased by 5-10 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com