Method of improving PHA synthesis yield of residual active sludge by native PHA synthesis bacteria refilling process

An activated sludge, native high-yield technology, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of restricting popularization and application, low yield, etc., and reduce production costs , increase yield, inhibit growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

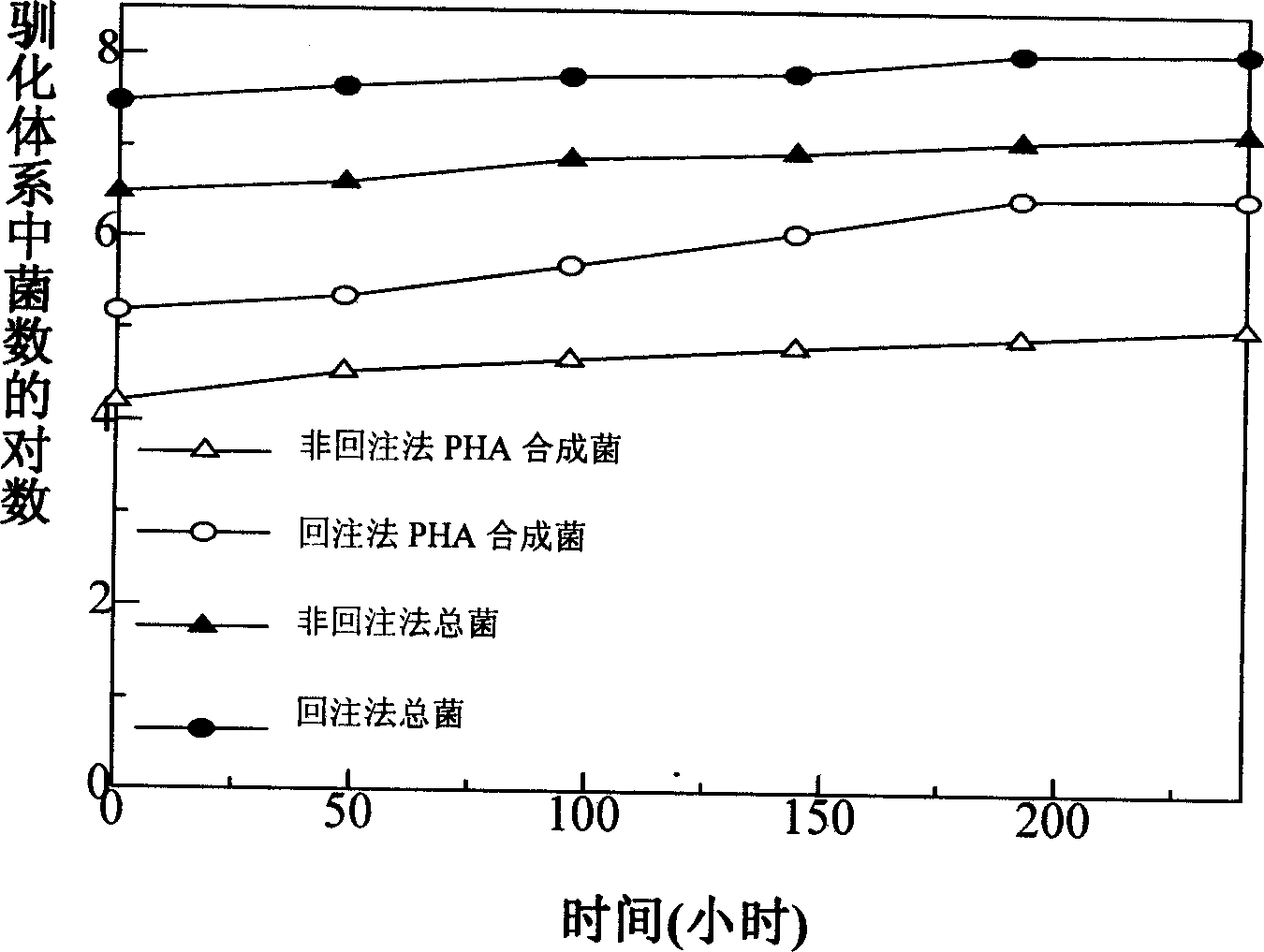

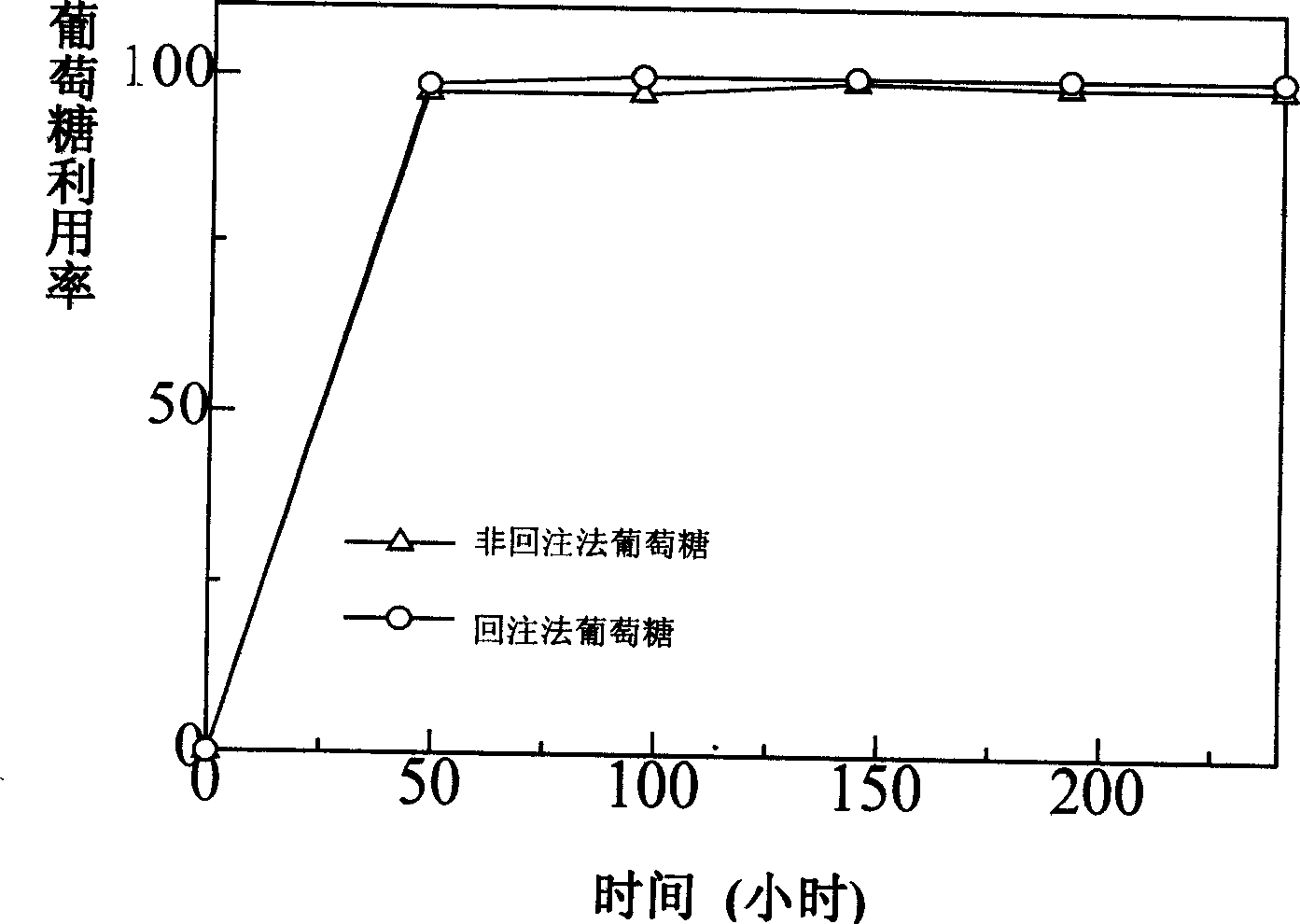

[0019] Using reinjection single high-yield native PHA synthetic bacteria to increase the yield of PHA synthesis in sludge (activated sludge in aerobic pool of domestic and a small amount of industrial wastewater treatment plant).

[0020] 1. Test equipment

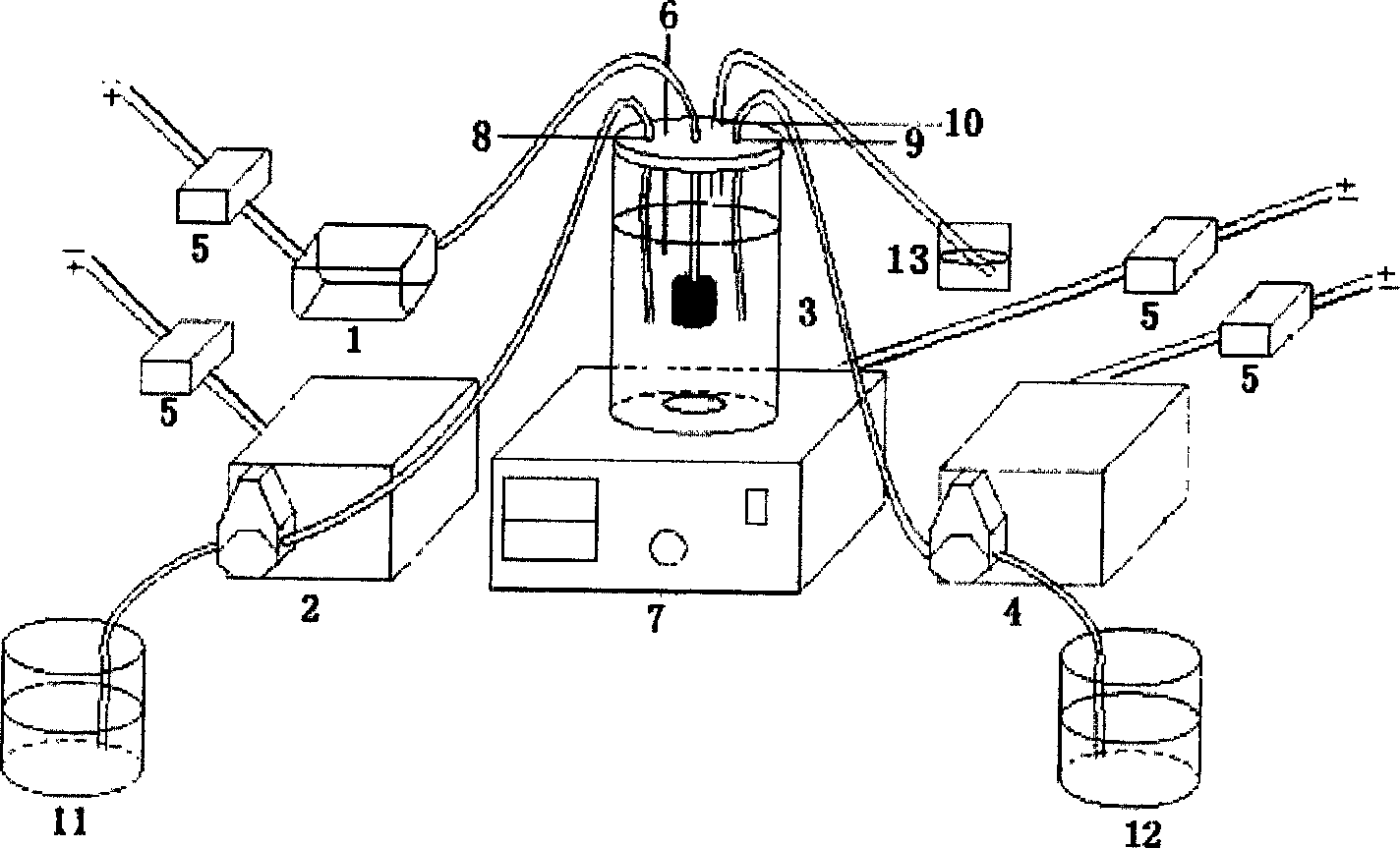

[0021] 1.1 Biological reaction tank

[0022] This test uses a 3-liter self-made reaction barrel as a biological reaction barrel. The top of the reaction barrel has a liquid inlet, a liquid outlet, an exhaust hole and a thermometer hole, and a built-in magnetic rotor. The biological reaction barrel is placed in a constant temperature water bath with magnetic stirring function. inside the device to ensure a constant temperature during the reaction.

[0023] 1.2 Gas supply system

[0024] The air pump used in this test can accurately control the amount passed into the reaction barrel to be 1.2L / min.

[0025] 1.3 Drainage and replenishment constant flow pump

[0026] The constant-flow pump can absorb liquid at a uniform sp...

Embodiment 2

[0065] Using reinjection mixed with high-yielding indigenous PHA synthetic flora to increase the yield of PHA synthesis in sludge (activated sludge in aerobic pools of domestic and industrial wastewater treatment plants).

[0066] 1. Test equipment

[0067] Same as Example 1

[0068] 2. Procedure

[0069] 2.1 The preparation of acclimatization liquid is the same as that in Example 1

[0070] 2.2 Fermentation broth preparation is the same as in Example 1

[0071] 2.3 PHA synthetic bacteria isolation and counting medium preparation is the same as in Example 1

[0072] 2.4 The preparation of the culture medium for counting the total number of bacteria is the same as in Example 1

[0073] 2.5 Adopt the Nile-Red method to isolate and obtain three strains of high-yielding indigenous PHA synthetic bacteria. The method is the same as in Example 1

[0074] 2.6 Identification of high-yielding indigenous PHA-synthesizing bacteria: the three isolates of high-yielding indigenous PHA-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com