Preparation method of silane coupled nanometer magnetic composite ferroferric oxide material

A technology of ferroferric oxide and nano-magnetism, which is applied in the field of nano-material manufacturing to achieve the effects of simple operation steps, uniform particle size distribution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

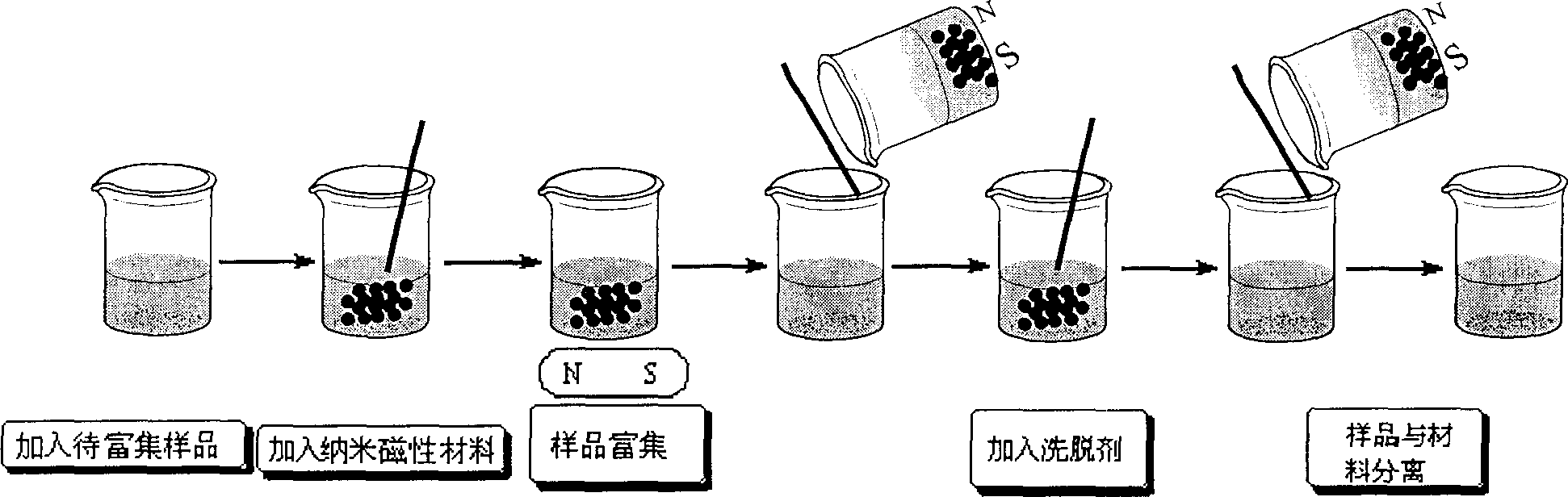

[0022] Weigh a certain amount of prepared nano-Fe 3 o 4 Particles are added with a dispersing solvent, ultrasonically washed, and magnetically separated to remove impurities. The dispersion solvent is added again. Under the protection of inert gas, slowly add a certain amount of silane coupling reagent. Under the condition of heating and constant temperature, the reaction was vigorously stirred. After the reaction is over, the product is washed and magnetically separated. Vacuum-dried to obtain a silanized nano-magnetic composite material.

[0023] The dispersing solvent is a hydrocarbon or alcohol solvent, and the best dispersing solvent is a saturated hydrocarbon, substituted benzene or saturated fatty alcohol solvent; the dispersing solvent is the best after dewatering; the ultrasonic treatment time is 0.5 -5 hours, the best time is 1-1.5 hours; the inert gas is nitrogen or argon, nitrogen is the best; the silane coupling reagent is saturated carbon chain trichlorosila...

Embodiment 1

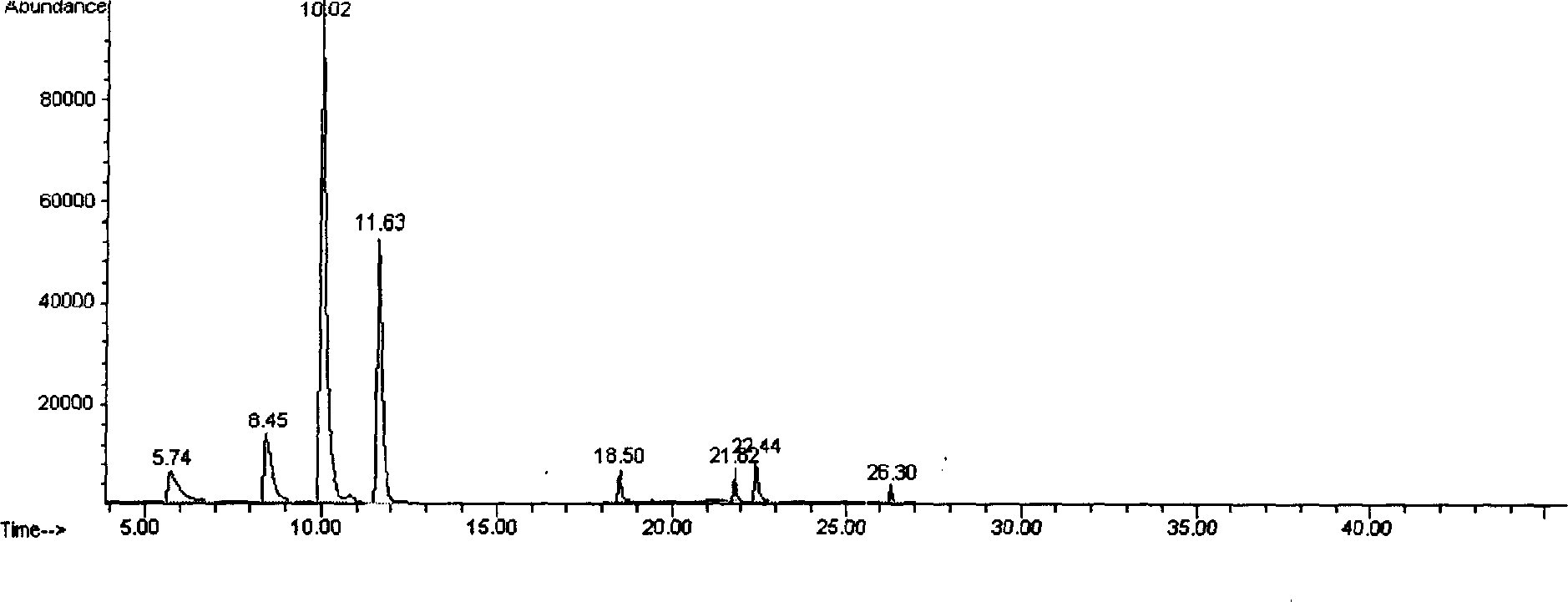

[0034] Application of silanized nano-magnetic composite materials to enrich trace plasticizers in plastic products for food packaging, and determine trace plasticizers in plastic products for food packaging by GC-MS

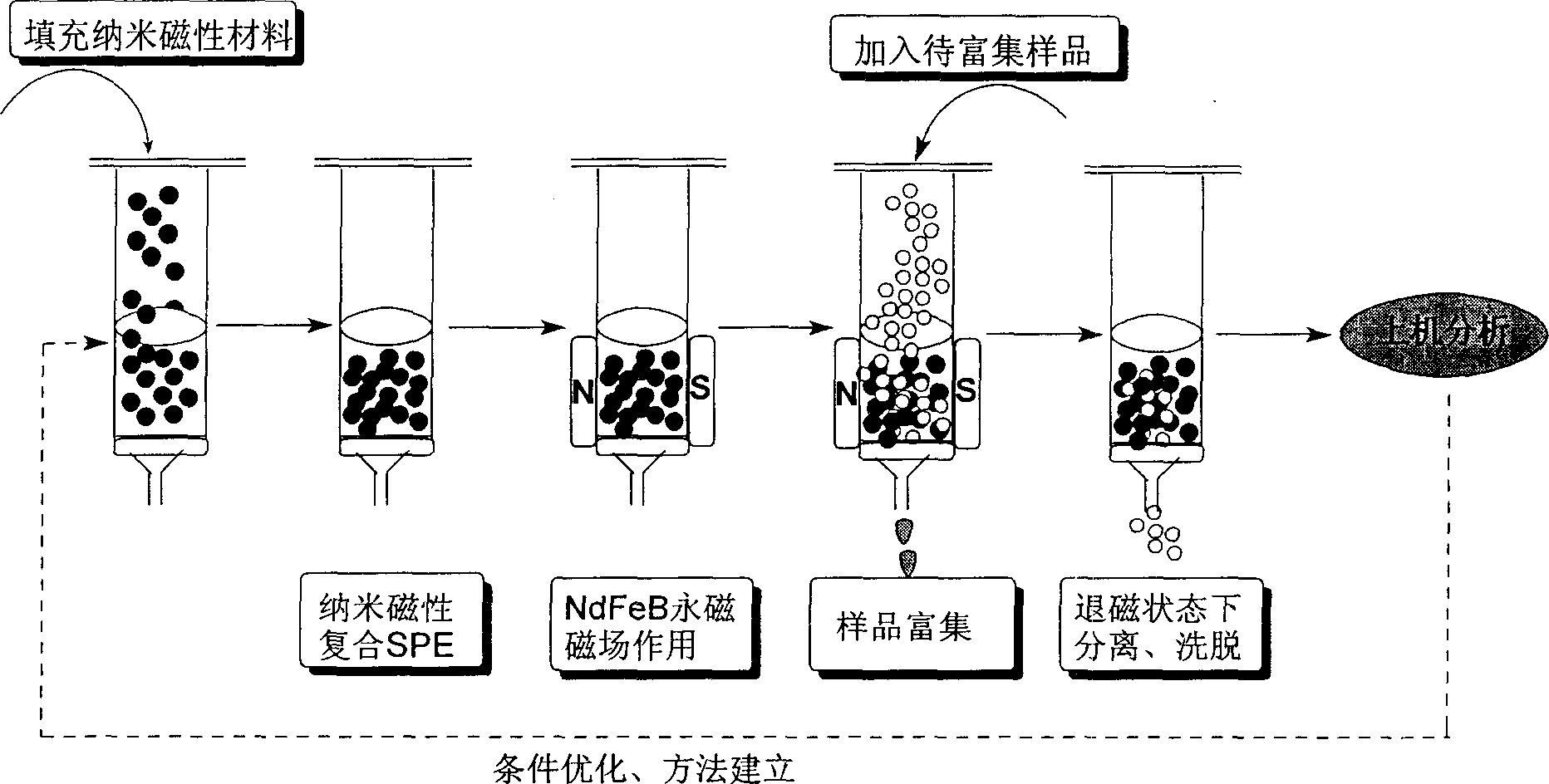

[0035] Accurately weigh about 1g of plastic products for food packaging into a 10mL graduated test tube, add standards containing eight kinds of plasticizers, namely: ethyl phthalate (DEP), propyl phthalate (DPP), phthalate Butyl formate (DBP), ethylphenyl phthalate (BBP), cyclohexyl phthalate (DCHP), ethylheptyl phthalate (DEHP), octyl phthalate (DOP) standard solution, add 10mL of n-hexane, ultrasonically extract for 30min, transfer the extract to another dry graduated test tube, blow it with nitrogen until it is nearly dry, and wait for the solid phase extraction column to be further purified. Add 3g of silanized nano-magnetic composite material to a 5mL syringe cushioned with glass wool, and fill it up under vacuum to make a small column for solid phase extra...

Embodiment 2

[0037] Application of silanized nano-magnetic composite materials to enrich various organophosphorus pesticides in food (including vegetables, fruits, poultry meat, aquatic products, dry goods, etc.), and gas chromatography (nitrogen and phosphorus detector) to simultaneously determine various organophosphorus pesticides in food

[0038] Accurately weigh about 5g of food samples into a 50mL centrifuge tube, add 20mL of acetone, ultrasonically extract for 10min, and centrifuge at a centrifugal speed of 5000r / min. Separate 10mL of the extract into another dry graduated test tube. Add 3 g of silanized nano-magnetic composite material to the extract, and stir for about 5 minutes, so that the silanized nano-magnetic composite material and the extract are fully contacted and magnetically separated. Solvent was discarded. The adsorption components of the silanized nano-magnetic composite material were washed with 5 mL of 50% acetone-ethyl acetate solution, magnetically separated aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com