Process of preparing active carbon with high specific surface area and process of making super capacitor

A high specific surface area, supercapacitor technology, applied in the direction of capacitors, electrolytic capacitors, fixed capacitor electrodes, etc., can solve the problems that ordinary activated carbon is not suitable, and achieve the effect of simple and fast charging and discharging, wide temperature range and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of preparation method of activated carbon with high specific surface area, the steps are:

[0031] (1) Take petroleum coke, dry it in an oven at 100°C-120°C, cool it naturally to normal temperature, and pulverize it to pass through a 100-mesh sieve;

[0032] (2) Take KOH and petroleum coke by weighing the mass ratio of KOH and petroleum coke powder as 5: 1, mix uniformly;

[0033] (3) The mixture is placed in a nickel crucible, heated to 850° C. in a protective atmosphere (nitrogen), and kept for 4 hours;

[0034] (4) Cool to normal temperature with the furnace, wash with deionized water to neutral after taking it out;

[0035] (5) drying, that is to say.

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of activated carbon of high specific surface area, the steps are:

[0037] (1) Take petroleum coke, dry it in an oven at 100°C-120°C, cool it naturally to normal temperature, and pulverize it to pass through a 100-mesh sieve;

[0038] (2) Take KOH and petroleum coke powder by weighing the mass ratio of KOH and petroleum coke powder as 2: 1, mix uniformly;

[0039] (3) Place the mixture in a nickel crucible, heat it to 950°C in a protective atmosphere (argon), and keep it warm for 2 hours;

[0040] (4) naturally cool to normal temperature with the furnace, wash with deionized water to neutrality after taking it out;

[0041] (5) drying, that is to say.

Embodiment 3

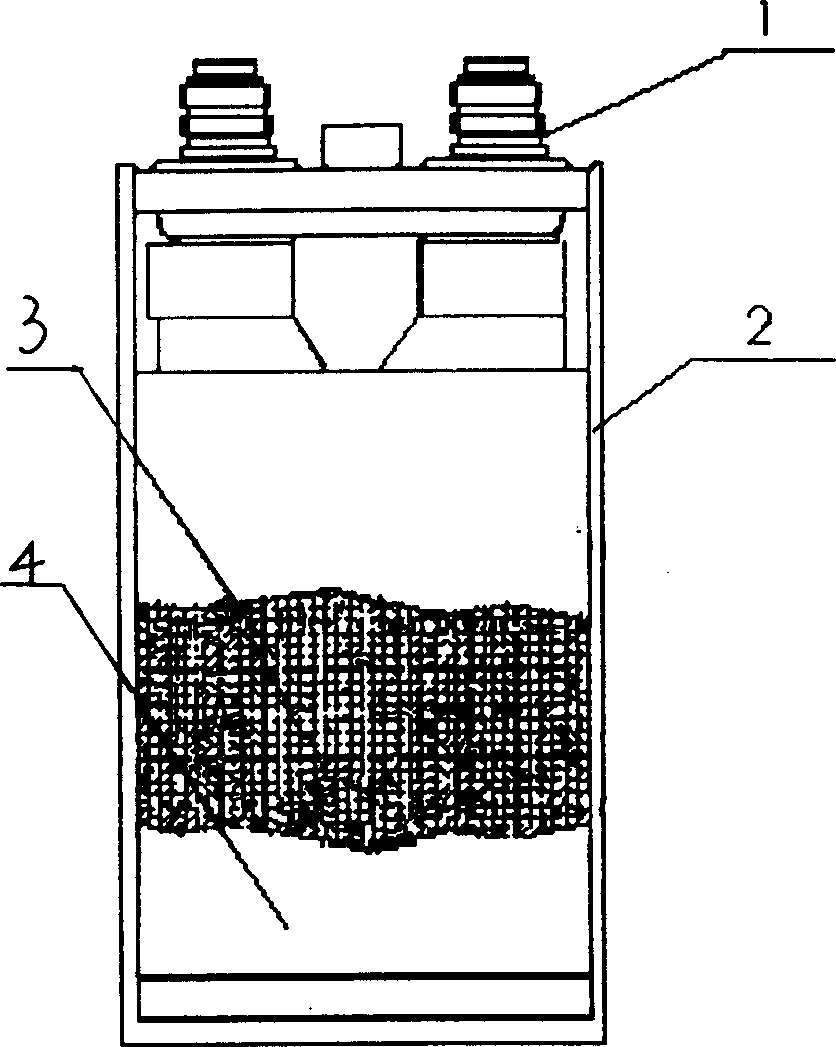

[0042] Embodiment 3: a kind of supercapacitor manufacturing method, its steps are:

[0043] (1) Preparation of activated carbon electrode:

[0044] a. Take the specific surface area as 2000-3000m 2 / g, high specific surface area activated carbon with mesoporosity ≥ 50%, ground to a particle size of less than 0.075mm;

[0045] b. Add 5% PTFE emulsion, 5% conductive graphite powder, and 0.5% CMC according to the mass ratio, and stir at a high speed to make it a uniformly mixed slurry;

[0046] c. coating the slurry on the nickel foam and drying;

[0047] d. Use a finish rolling mill to roll into electrode sheets with a thickness of 0.1-0.5mm;

[0048] (2) A modified non-woven fabric diaphragm is arranged between two adjacent electrode sheets;

[0049] (3) Several (such as 3-15, etc.) electrode sheets are connected in parallel, and the two poles of the electrode sheets are respectively welded on the two poles, and then put into the plastic shell;

[0050] (4) Pour KOH soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com