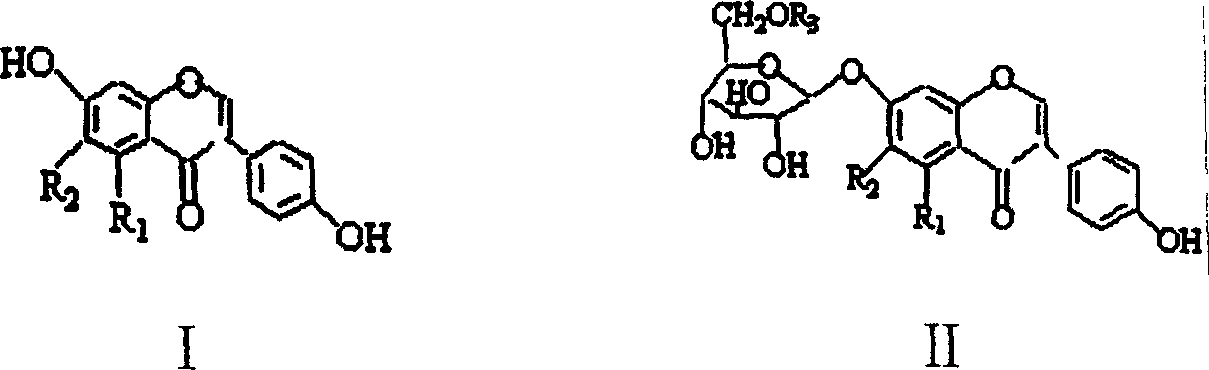

Method for preparing flavone aglycone micro capsule

A technology of flavone aglycone and microcapsules, which is applied in the field of preparation of flavone aglycone microcapsules, can solve the problems of losing physiological functions, limiting the scope of application, reducing biological activity, etc., achieving easy separation and purification, widening the scope of application, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 6.0g of soybean isoflavone aglycone obtained after acid hydrolysis, and dissolve it in 100ml of absolute ethanol; weigh 12g of gelatin and dissolve it in 100ml of water, weigh 42g of maltodextrin and dissolve it in 200ml of water, and weigh 0.2g of sodium alginate Dissolve in 5ml of water. After all the materials are dissolved, use a magnetic stirrer to fully mix the gelatin solution and maltodextrin solution, and then slowly add the soybean isoflavone aglycon ethanol solution dropwise into the mixed solution of gelatin and maltodextrin , the dropping rate is controlled at 5ml / min. After all the solutions are mixed, disperse for 15 minutes using a powerful disperser. Then homogenize under the pressure of 20MPa, spray dry after homogenization, the inlet air temperature is 180°C, and the outlet air temperature is 80°C. The product is stored in a sealed sample bag.

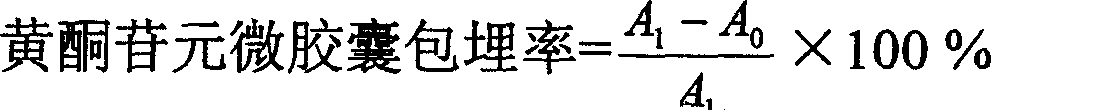

[0025] Weigh two products of about 70 mg, one of which is dissolved in absolute ethanol to determin...

Embodiment 2

[0027] Weigh 9g of ginkgo flavonoid aglycone obtained after acid hydrolysis, and dissolve it in 100ml of 95% ethanol; weigh 13.5g of soybean protein isolate and dissolve it in 100ml of 50°C water, weigh 37.5g of maltodextrin and dissolve it in 200ml of water, and weigh 0.1g Sodium alginate was dissolved in 5ml of water, and 0.3g of monoglyceride was weighed and dissolved in 5ml of water. After all the materials are dissolved, first use a magnetic stirrer to fully mix the soybean protein isolate solution and maltodextrin solution, and then slowly add the acid-decomposed ginkgo leaf flavonoid ethanol solution dropwise to the soybean protein isolate and maltodextrin In the mixed solution, the dropping rate is controlled at 7ml / min. After all the solutions are mixed, use a powerful disperser to disperse for 10 minutes. Then homogenize under the pressure of 30MPa, spray dry after homogenization, the inlet air temperature is 200°C, and the outlet air temperature is 90°C. The produc...

Embodiment 3

[0030] Weigh 12.0g of soybean isoflavone aglycone obtained after enzymatic hydrolysis, and dissolve it in 100ml of 95% ethanol; weigh 15g of whey protein and dissolve it in 100ml of 45°C water, weigh 33g of maltodextrin and dissolve it in 200ml of water, and weigh 0.3 Dissolve g sodium alginate in 5ml water, weigh 0.1g monoglyceride and dissolve it in 5ml water. After all the materials are dissolved, use a magnetic stirrer to fully mix the lactoprotein solution and the maltodextrin solution, and then slowly add the enzymatic soy isoflavone ethanol solution to the whey protein and maltodextrin In the mixed solution, the dropping speed is controlled at 10ml / min. After all the solutions are mixed, disperse for 10min with a powerful disperser. Then homogenize under the pressure of 40MPa, spray dry after homogenization, the inlet air temperature is 220°C, and the outlet air temperature is 100°C. The product is stored in a sealed sample bag.

[0031] Weigh two products of about 70 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com