Production of oxide copper nanometer tube array

A technology of nanotube array and copper oxide, which is applied in the direction of nanostructure manufacturing, copper oxide/copper hydroxide, nanotechnology, etc., can solve the problems that nanotube arrays are easily damaged and application limitations, and meet the requirements and are easy to achieve, methods Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of copper hydroxide nanotube arrays at low temperature

[0029] Follow the steps below:

[0030] 1. Prepare a copper foil with a size of 1.5-1.0×1.5-0.3×0.3 cubic centimeters, and clean it in an ultrasonic cleaner with acetone or dilute nitric acid to remove impurities on the surface of the copper foil;

[0031] 2. Prepare a sodium hydroxide solution with a concentration of 2.0-3.0 mol / liter and an ammonium persulfate solution with a concentration of 1 mol / liter;

[0032] 3. Take 20-30 ml of the prepared sodium hydroxide solution, put the prepared copper foil into it, and then inject 2.0-4.0 ml of the prepared ammonium persulfate solution, so that the molar ratio of the sodium hydroxide solution and the ammonium persulfate solution The ratio is 20-30:1;

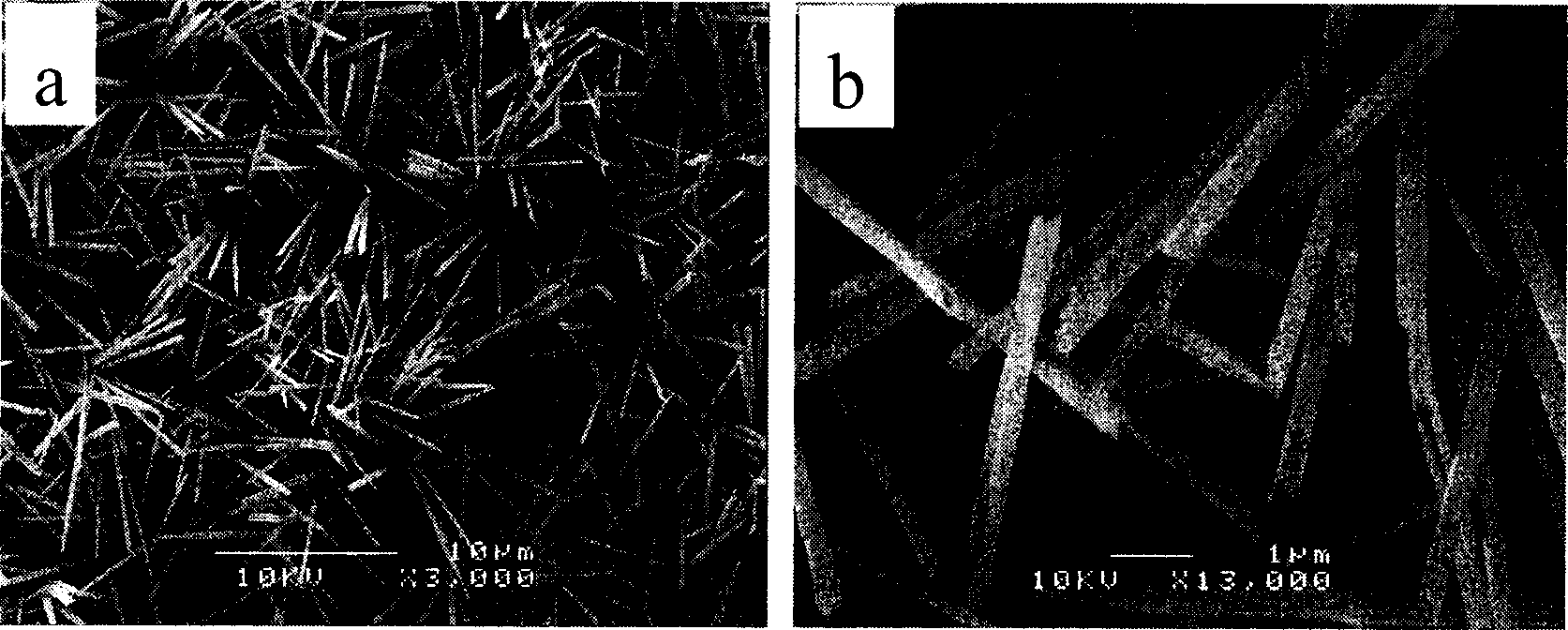

[0033] 4. React at a temperature of 0-5°C, and after 5-25 hours, obtain copper foil-based growth with Cu(OH) 2 products of nanotube arrays;

[0034] 5. Wash the obtained product with distille...

Embodiment 2

[0036] Example 2: Preparation of copper hydroxide nanotube arrays at room temperature

[0037] Follow the steps below:

[0038] 1, with step 1 in embodiment 1;

[0039] 2, with step 2 in embodiment 1;

[0040] 3, with step 3 in embodiment 1;

[0041] 4. React at room temperature, after 0.5-5.0 hours, obtain copper foil as the substrate with growth of Cu(OH) 2 products of nanotube arrays;

[0042] 5. Same as step 5 in Example 1.

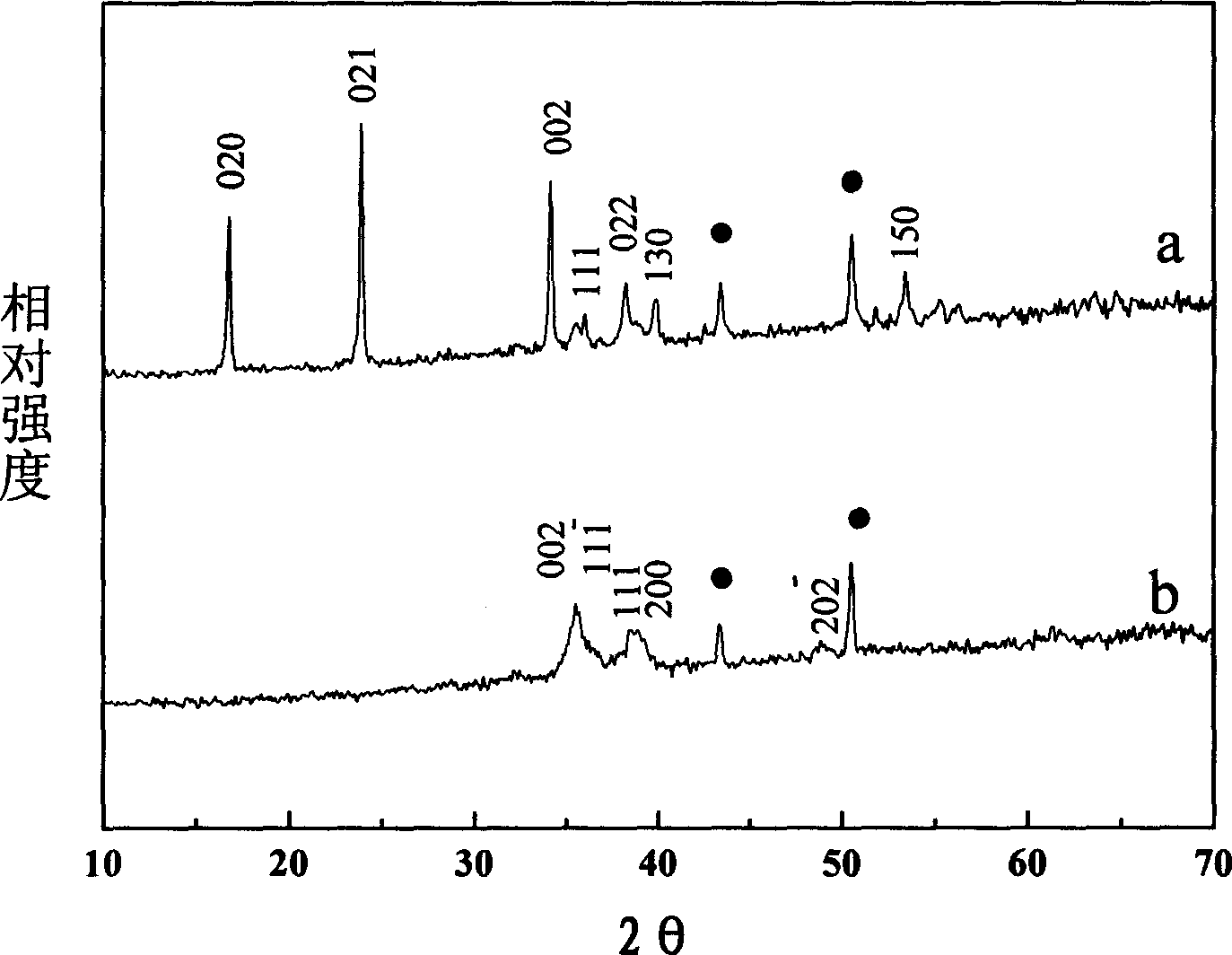

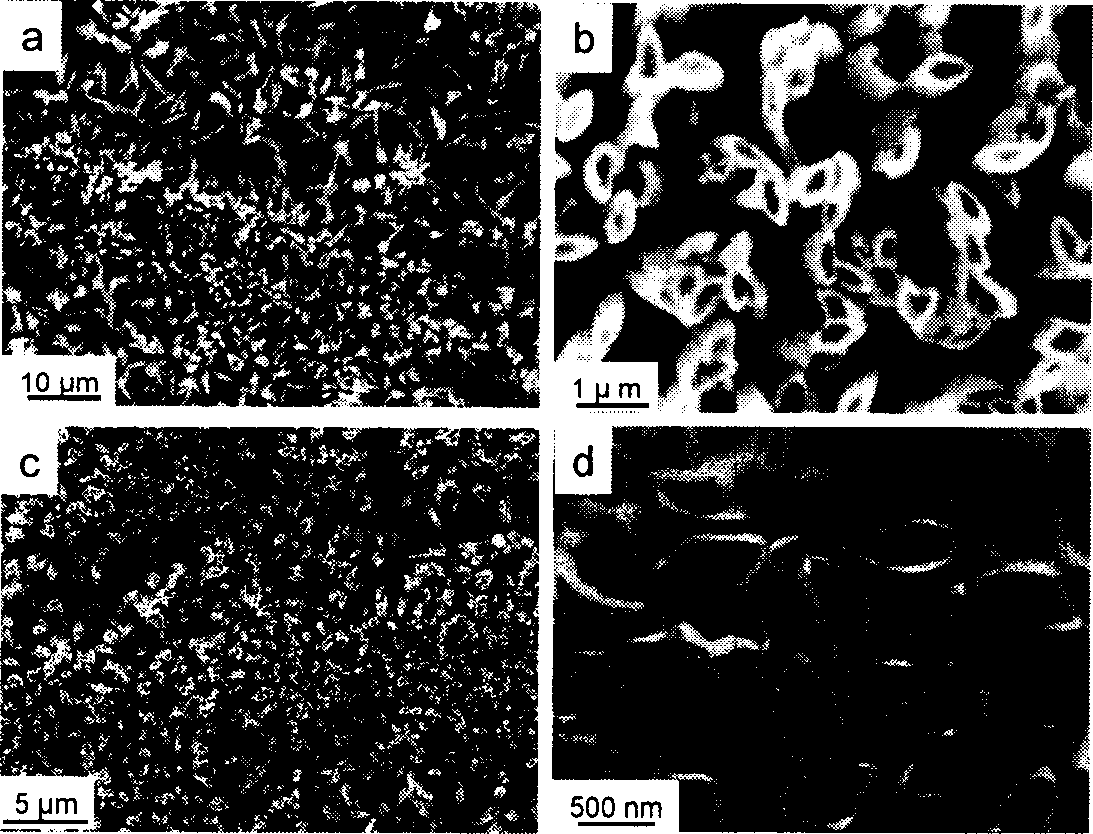

[0043] The difference from Example 1 is that in step 4 of this example, normal temperature is used as the reaction condition, and the product obtained from the normal temperature reaction is also orthorhombic Cu(OH) 2 , verified by X-ray diffraction XRD analysis. image 3 Middle a (low magnification) and b (high magnification) are scanning electron microscope SEM images, analysis shows that Cu(OH) produced under normal temperature conditions 2The length of the nanotubes is mostly about 5-10 microns, the diameter of the tubes is between 50-500nm...

Embodiment 3

[0044] Embodiment 3: Preparation of copper oxide nanotube array

[0045] The copper hydroxide nanotube array prepared in Example 1 is placed in a tube furnace. Since the array is grown on the copper foil substrate, in order to avoid the oxidation of the substrate, the array grown on it needs to be processed under a protective atmosphere. Transformation by heating. The specific operation is to inject 0.02m 3 Slowly feed nitrogen at a flow rate of about 15-30 minutes, remove the air in the tube furnace and heat at 60°C for 2 hours to preheat to avoid the temperature rising too fast and breaking the nanotube wall; then rise Heating to 120°C for 4 hours to complete Cu(OH) 2 The transformation of nanotube arrays to CuO nanotube arrays, and then kept at 180 ° C for 6 hours to enhance the crystallinity of CuO nanotubes, then stopped heating, cooled to room temperature in a natural state, and turned off the nitrogen source to obtain CuO nanotubes array.

[0046] X-ray diffraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com