Synthesis of TiO2 nanometer particles and bars

A synthesis method and nanoparticle technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of difficulty in obtaining high crystallinity, uniform size, inability to further assemble, industrial application limitations, etc. The effect of cheap raw materials and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

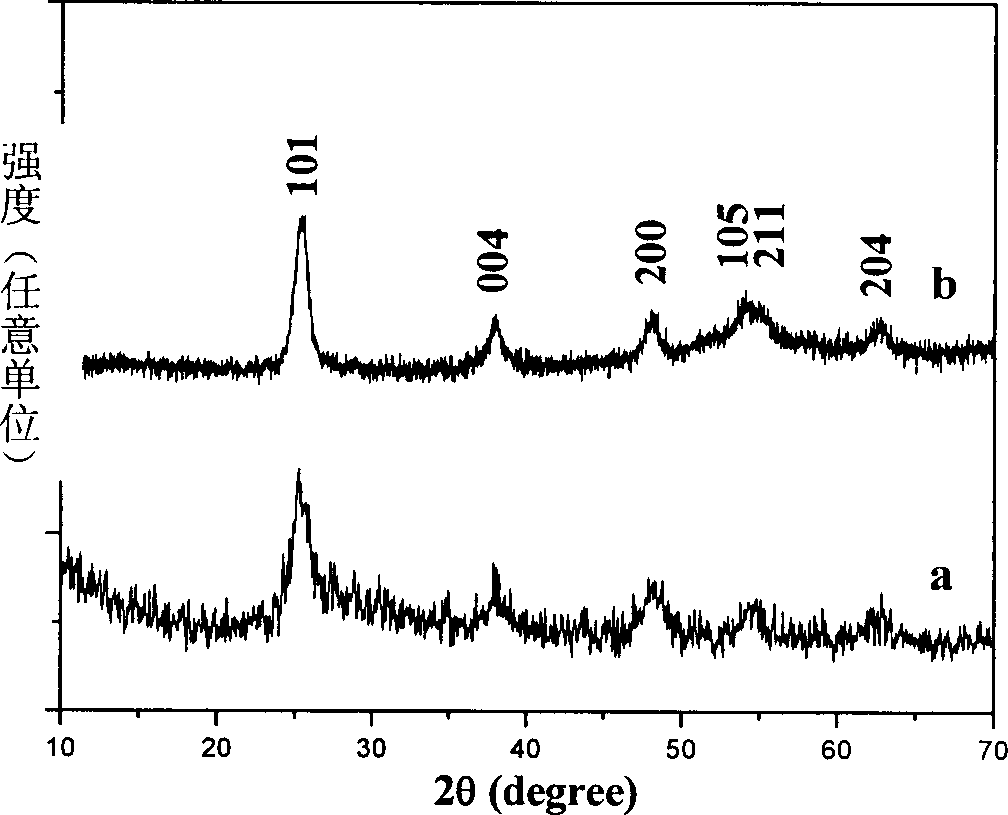

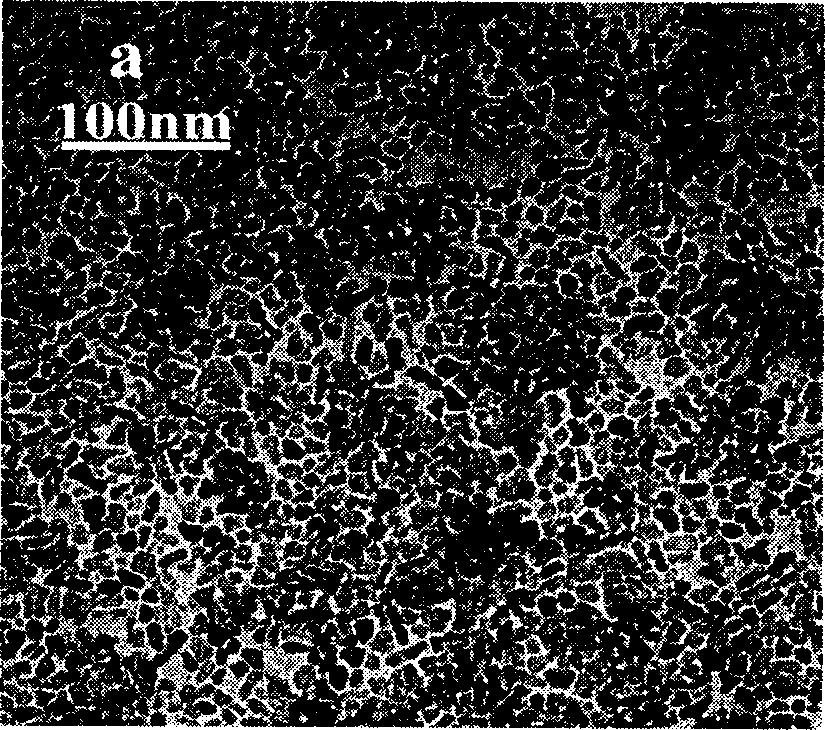

[0031] In typical TiO 2 During the synthesis of nanoparticles, the NH 4 HCO 3 (1g), linoleic acid (LA, about 25mL), triethylamine (5mL) and cyclohexane (5mL) were mixed uniformly with electromagnetic stirring at room temperature, and then the Ti(OBu) 4 (1 mL) was slowly added dropwise to the solution. Stir further at room temperature to make the system evenly mixed, then transfer the solution to a stainless steel hydrothermal kettle with a Teflon (Teflon) liner and react for several hours at 150°C to obtain high crystallinity, uniform size, and organic solvent redispersible TiO 2 nanoparticles.

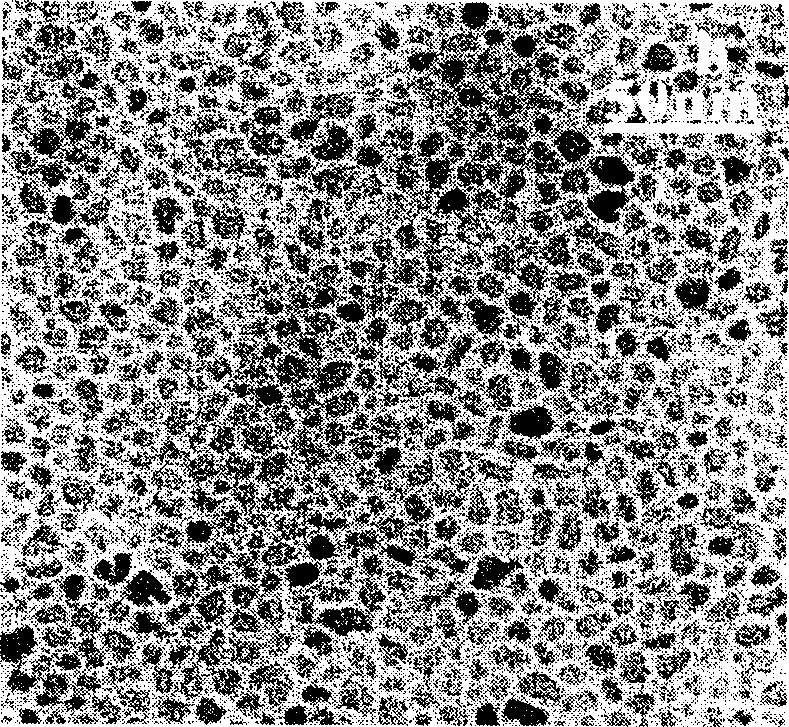

[0032] In typical TiO 2 During the synthesis of nanorods, linoleic acid (LA, about 7mL), triethylamine (5mL) and cyclohexane (15mL) were mixed uniformly with electromagnetic stirring at room temperature, and the Ti(OBu) 4 (1 mL) was slowly added dropwise to the solution. At room temperature, electromagnetically stir further to make the system evenly mixed, then transfer the solut...

Embodiment 2

[0035] In typical TiO 2 During the synthesis of nanoparticles, the NH 4 HCO 3 (0.5g), linoleic acid (LA, about 10mL), triethylamine (1mL) and cyclohexane (10mL) were mixed uniformly with electromagnetic stirring at room temperature. 2% SnCl 4 ·5H 2 O was added to the reaction system. Then Ti(OBu) 4 (2 mL) was slowly added dropwise to the solution. Stir further at room temperature to make the system evenly mixed, then transfer the solution to a stainless steel hydrothermal kettle with a Teflon (Teflon) liner and react at 180° C. for several hours. Under the same conditions, replace tetrabutyl titanate with organic titanates such as tetraisopropyl titanate, replace linoleic acid with long-chain organic acids such as dodecanoic acid and capric acid, and replace triethylamine with Replaced with organic amines such as dodecylamine, replaced cyclohexane with low-boiling organic solvents such as hexane, controlled the reaction temperature at 100, 150, and 200°C, and controlled...

Embodiment 3

[0037] In typical TiO 2 During the synthesis of nanoparticles, the NH 4 HCO 3 (2 g), linoleic acid (LA, about 5 mL), triethylamine (3 mL) and cyclohexane (5 mL) were mixed uniformly at room temperature with electromagnetic stirring. 1% FeCl 3 added to the reaction system. Then Ti(OBu) 4 (5mL) was slowly added dropwise to the solution. Stir further at room temperature to make the system evenly mixed, and then transfer the solution to a stainless steel hydrothermal kettle with a Teflon liner and react at 100°C for several hours.

[0038] Under the same conditions, replace tetrabutyl titanate with organic titanates such as tetraisopropyl titanate, replace linoleic acid with long-chain organic acids such as dodecanoic acid and capric acid, and replace triethylamine with Replaced with organic amines such as dodecylamine, replaced cyclohexane with low-boiling organic solvents such as hexane, controlled the reaction temperature at 100, 150, and 200°C, and controlled the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com