Production of high-quality ZnO nanometer capsule with semiconductive luminescent materials

A technology of luminescent materials and semiconductors, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of harsh process conditions, high reaction temperature and energy consumption, expensive production equipment, etc., and achieves wide range of process conditions and reaction temperature. and the effect of low energy consumption and excellent photoluminescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Choose 1 gram of zinc acetate (Zn(AC) 2 2H 2 O) powder, added to the concentration of 3% hydrogen peroxide (H 2 o 2 ) solution and fully stirred and dissolved; after the dissolution was complete, adjust its pH value to 10 with ammonia water, then put it into a closed high-pressure reactor, and carry out a hydrothermal reaction at 200°C and its own pressure for 12 hours; suction filter the solid product out, washed with distilled water, and dried to obtain the desired product ZnO nanocapsules.

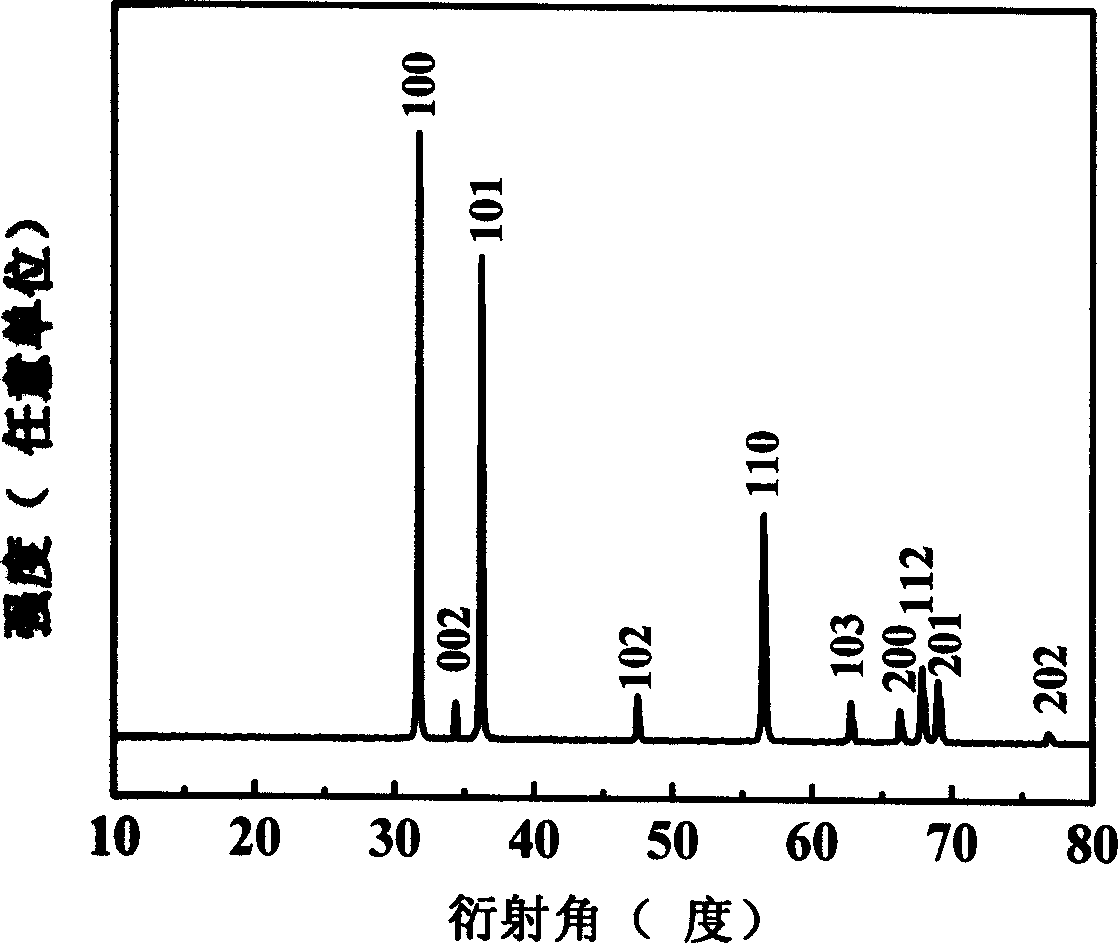

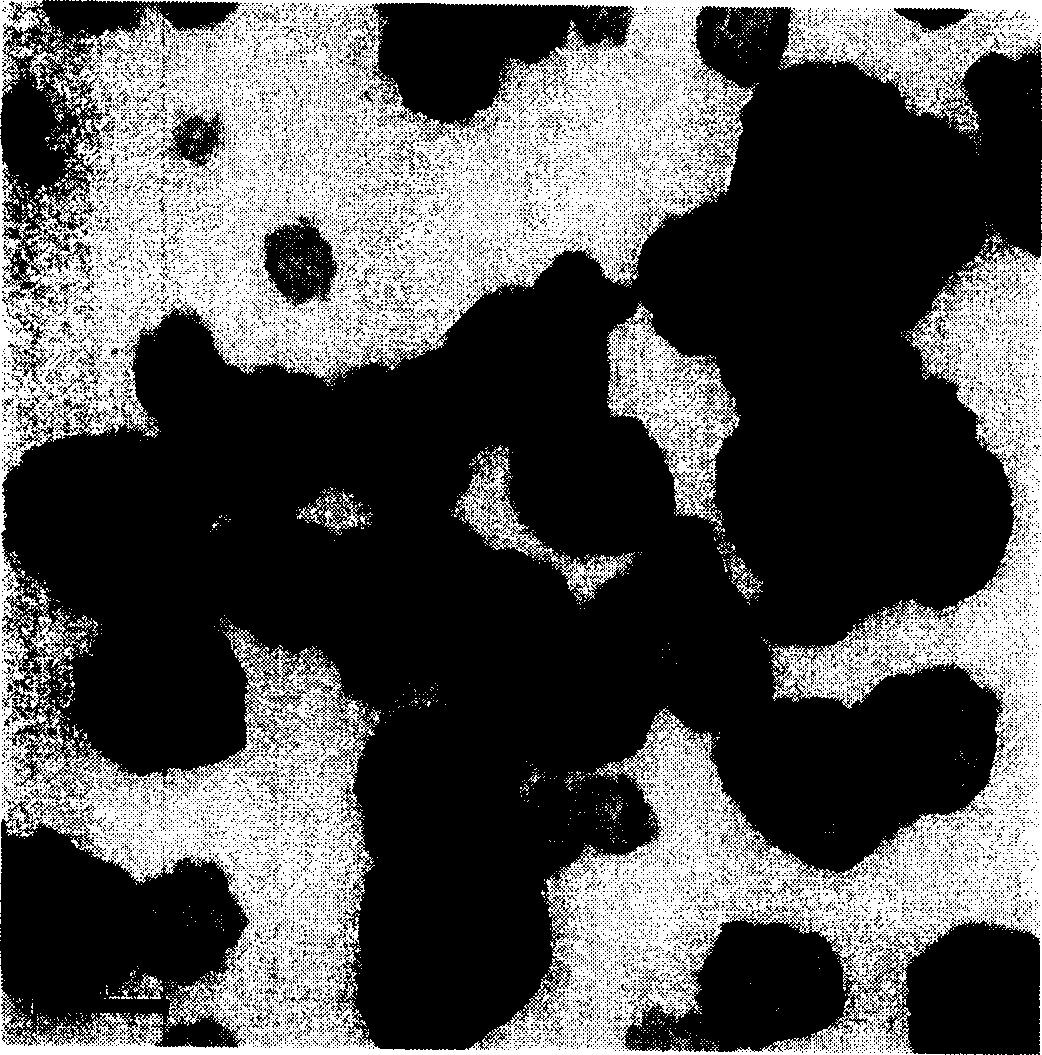

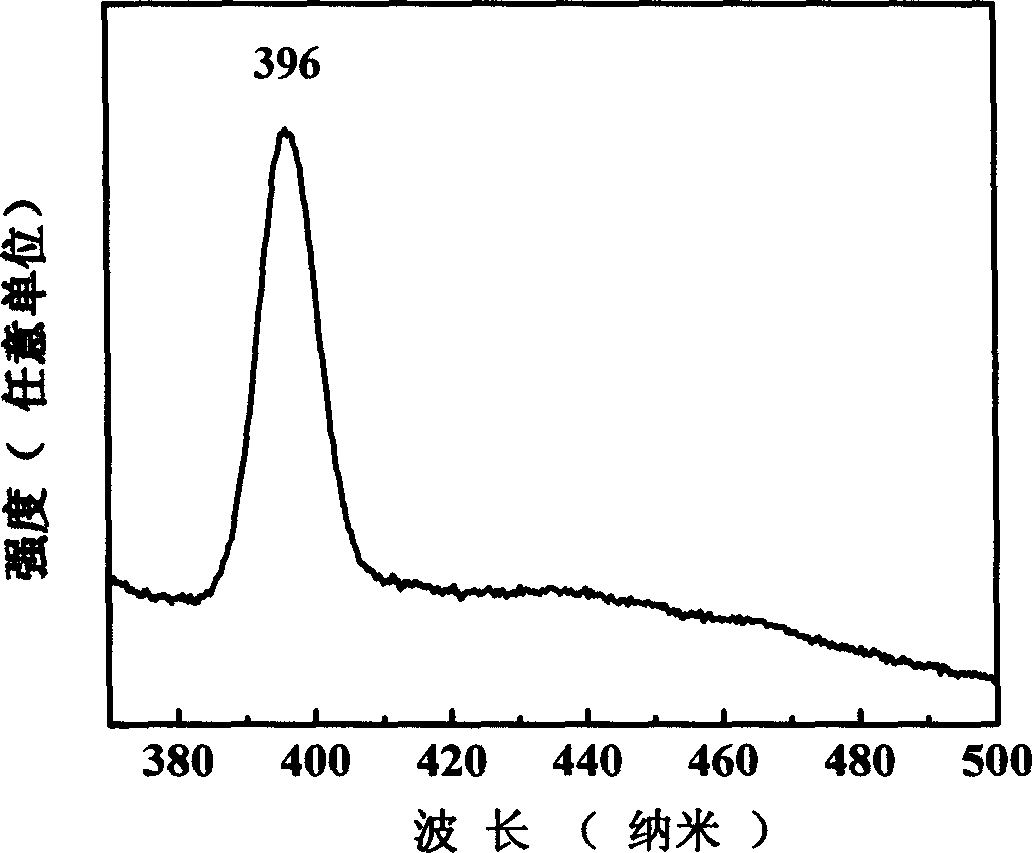

[0025] Such as figure 1 , figure 2 , image 3 As shown, adopt Japan Rigaku D / Max-3C X-ray powder diffractometer (Cu Kα radiation, λ=1.5406 ) to measure the crystal structure of prepared material; The morphology and size of the product were observed; the luminescence performance of the product was tested by a Japanese Hitachi F-4500 fluorescence spectrometer, and an Xe lamp was selected as the excitation light source at room temperature, and the excitation wavelength was 3...

Embodiment 2

[0031] Choose 1 gram of zinc acetate (Zn(AC) 2 2H 2 O) powder, added to the concentration of 30% hydrogen peroxide (H 2 o 2 ) solution and fully stirred and dissolved; after the dissolution was complete, adjust its pH value to 8 with ammonia water, then put it into a closed high-pressure reactor, and carry out a hydrothermal reaction at 200 ° C and its own pressure for 12 hours; the solid product was suction filtered out, washed with distilled water, and dried to obtain the desired product ZnO nanocapsules.

[0032] Such as Figure 4 , Figure 5 , Figure 6 As shown, adopt Japan Rigaku D / Max-3C X-ray powder diffractometer (Cu Kα radiation, λ=1.5406 ) to measure the crystal structure of prepared material; The shape and size of the product were observed. A Japanese Hitachi F-4500 fluorescence spectrometer was used to test the luminescence performance of the product, and an Xe lamp was selected as the excitation light source at room temperature, and the excitation wavelen...

Embodiment 3

[0038] Choose 1 gram of zinc acetate (Zn(AC) 2 2H 2 O) powder, added to the concentration of 3% hydrogen peroxide (H 2 o 2 ) solution and fully stirred and dissolved; after the dissolution was complete, adjust its pH value to 9 with ammonia water, then put it into a closed high-pressure reactor, and perform a hydrothermal reaction at 190°C and its own pressure for 18 hours; suction filter the solid product out, washed with distilled water, and dried to obtain the desired product ZnO nanocapsules.

[0039] Such as Figure 7 , Figure 8 , Figure 9As shown, adopt Japan Rigaku D / Max-3C X-ray powder diffractometer (Cu Kα radiation, λ=1.5406 ) to measure the crystal structure of prepared material; The morphology and size of the product were observed; the luminescence performance of the product was tested by a Japanese Hitachi F-4500 fluorescence spectrometer, and an Xe lamp was selected as the excitation light source at room temperature, and the excitation wavelength was 325...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com