Luetcium aluminum garnet -base transparent ceramic and process for preparing same

A lutetium-aluminum garnet and transparent ceramic technology is applied in the field of fine ceramic preparation of rare earth oxide-containing transparent products, can solve problems such as restricting practical application prospects, and achieve the effects of low porosity, narrow grain distribution, and high ray absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

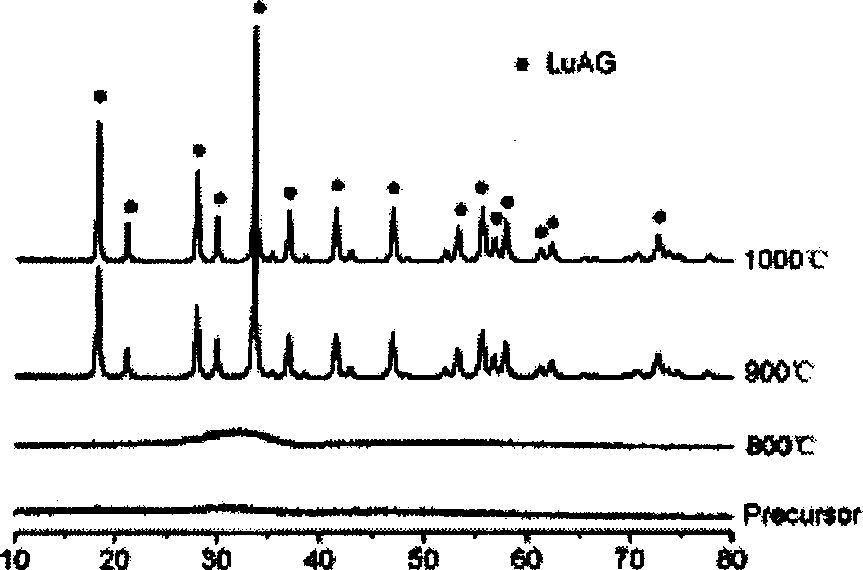

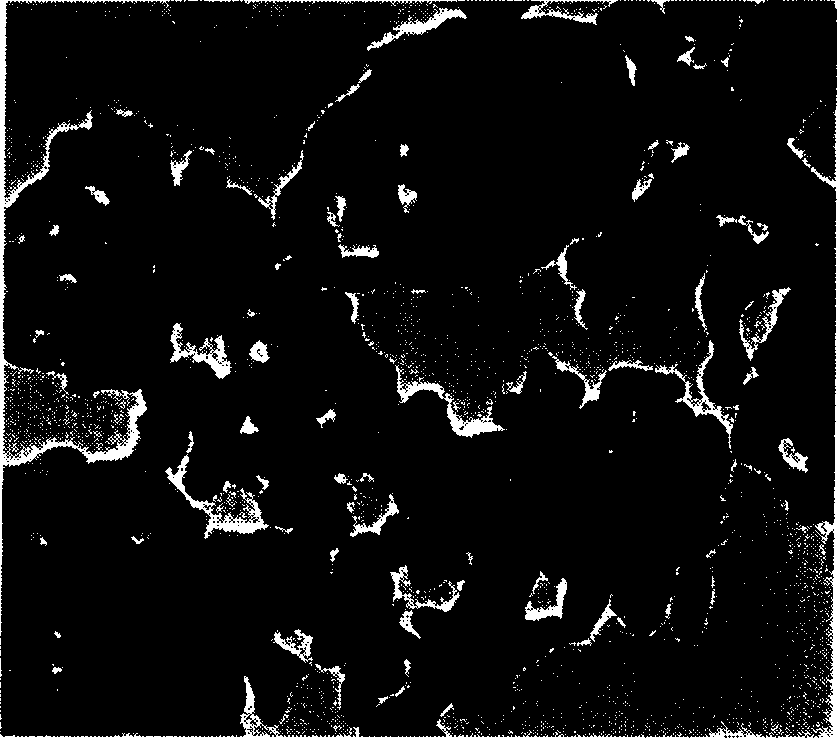

[0032] High-purity lutetium oxide (4N), cerium oxide (4N) and analytically pure aluminum nitrate are formulated according to the strict ratio of atomic ratio Lu: Ce: Al = 2.985: 0.015: 5, respectively dissolved in high-grade pure nitric acid and double distilled water Preparation of Al from lutetium oxide, ceria and aluminum nitrate 3+ Mixed salt solution with a concentration of 0.1-0.3M, and then dissolve an appropriate amount of analytically pure urea in the mixed salt solution to obtain an aqueous urea solution with a concentration of 1-3M; heat the mixed solution prepared above slowly while stirring, and after about 1 hour, water The temperature rises to 90-95°C, heat preservation and stirring for 2-3 hours, then stop heating, continue stirring for 5-10 hours, filter the precipitate, and then wash the filter cake with distilled water and absolute ethanol for 2-3 times, and put the filter cake at 120°C Dry it for 24 hours, then place it in a muffle furnace for calcination a...

Embodiment 2

[0034]With high-purity lutetium oxide (4N), praseodymium oxide (4N) and analytical pure aluminum nitrate by atomic ratio Lu: Pr: Al=2.976: 0.024: 5 strict ratio batching, then according to the test method described in embodiment 1, A LuAG:Pr (Pr doping concentration of 0.8at.%) transparent ceramic with a relative density of 99.9% is obtained. The transmittance of the transparent ceramic with a thickness of 1.0 mm is close to 70% in the visible light region.

Embodiment 3

[0036] High-purity lutetium oxide (4N), cerium oxide (4N) and analytically pure aluminum nitrate are formulated according to the strict ratio of atomic ratio Lu: Ce: Al = 2.985: 0.015: 5, respectively dissolved in high-grade pure nitric acid and double distilled water Preparation of Al from Lutetium Oxide, Ceria and Aluminum Nitrate 3+ A mixed salt solution with a concentration of 0.2-0.3M. Dissolve an appropriate amount of analytically pure glycine in the mixed salt solution according to the molar ratio of nitrate:glycine=3:5, and stir to form a uniform solution. The beaker containing the solution was placed on a magnetic stirrer, heated to 60°C and kept stirring, and a sol was formed after several hours. Raise the temperature to 80°C and continue stirring to form a yellow transparent gel. Put the gel into a box furnace preheated to 150 °C, and burn it to form light yellow-green loose precursor powder. The precursor powder was heat-treated at 1000 °C for 2 h in the air atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com