Dynamic and complete analysis system for dynamic electric current

A full analysis, current technology, applied in the field of flow analysis technology and full analysis system, can solve the problems of unsuitability for portability, field and process analysis, manufacturing and supporting micro-analytical systems, and large supporting instruments and detectors. The effect of no pulsation, low driving power and high working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

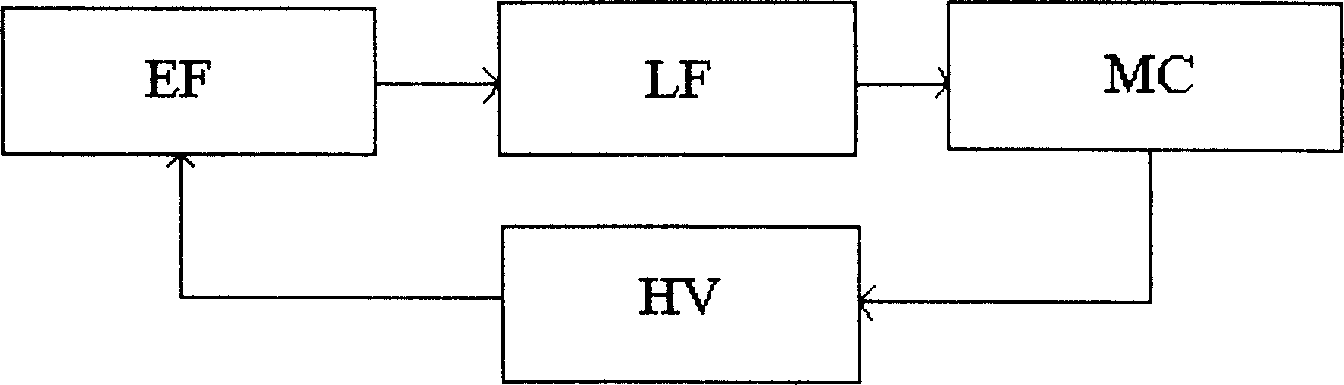

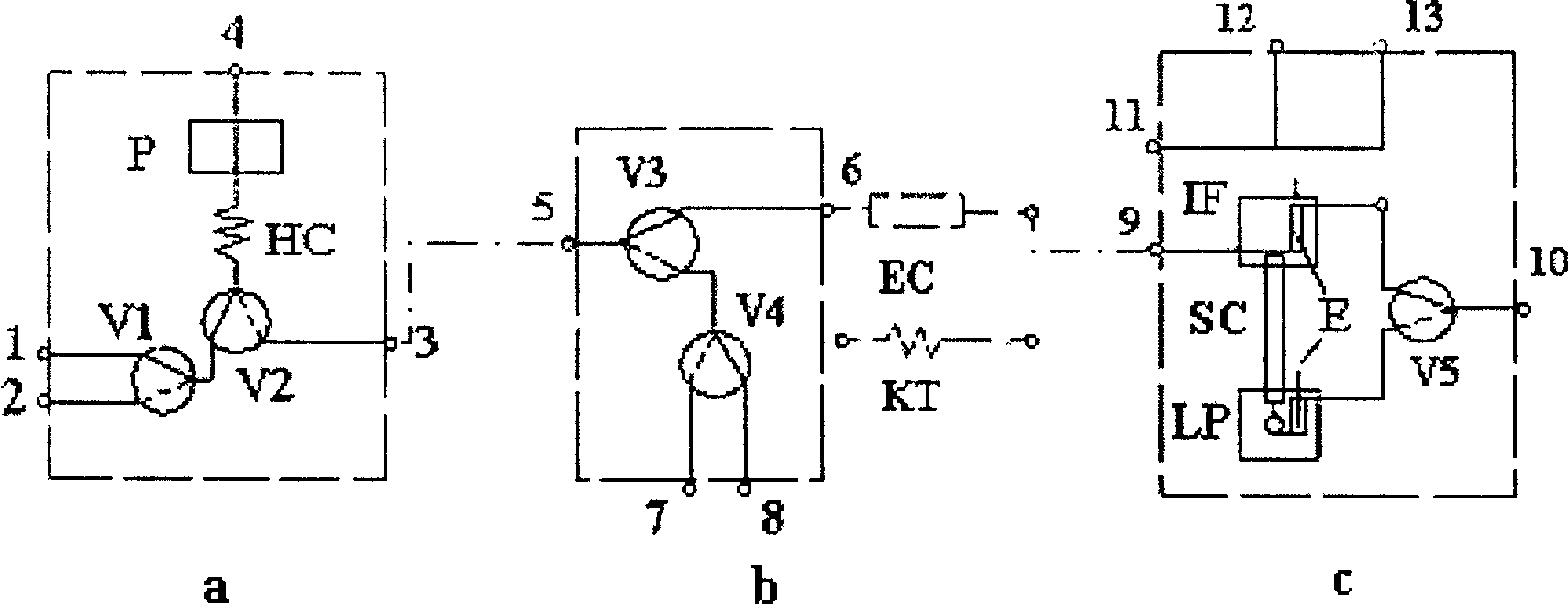

[0037] The electrogalvanic full analysis system consists of three basic analysis units combined with EF connections, including the electroosmotic pump injection reaction unit (see figure 2 a), enrichment functional unit (see figure 2 b), and the micro-column separation detection unit (see figure 2 c). exist figure 2 In , parts a, b and c in dotted boxes respectively show the schematic diagrams of the analysis flow paths of the three analysis units.

[0038] Electroosmotic pump injection reaction unit a is composed of an electroosmotic pump P, a solution storage ring HC and two electromagnetic switching valves V1 and V2, see figure 2 part a of Its analysis functions include sample and reagent solution injection, reaction and temporary storage in the storage ring HC, and transport of the reaction solution to the lower analysis unit. The electroosmotic pump P consists of a side-closed porous glass sand core column placed in the middle of the pump body, pump chambers at ...

Embodiment 2

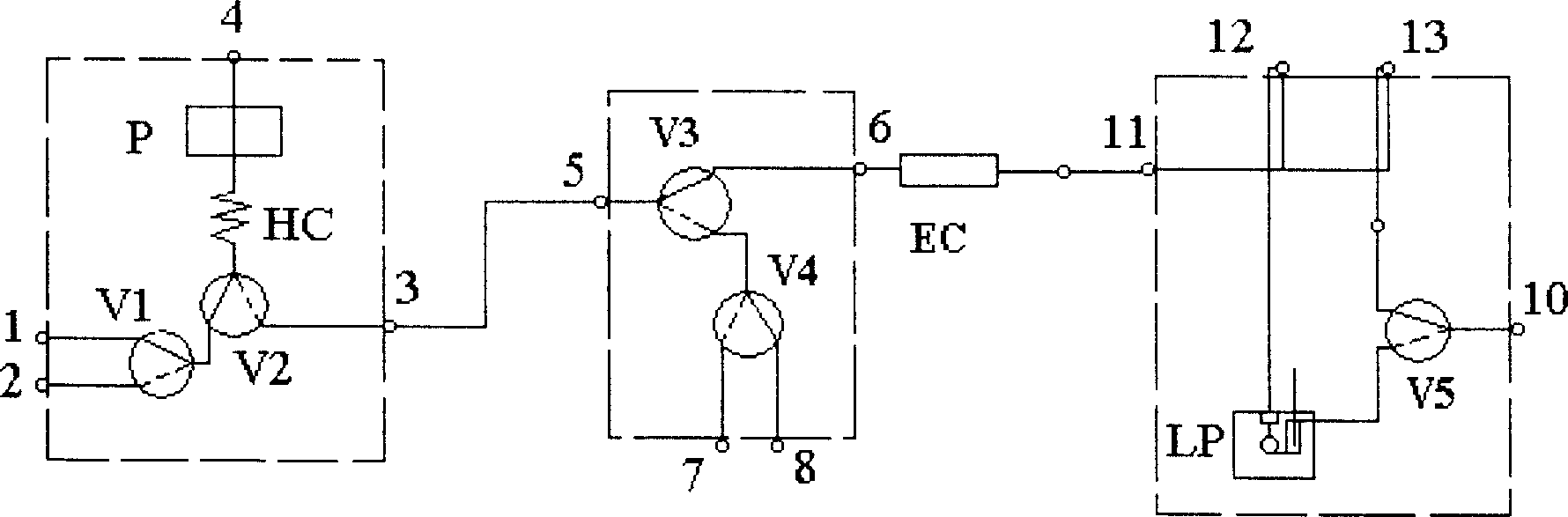

[0050] The injection, reaction, enrichment and detection analysis system is composed of an electroosmotic pump injection reaction unit a, an enrichment functional unit b, and a microcolumn separation detection unit c, the flow path of which is shown in image 3 . The electroosmotic pump P used in this example is the same as that of Example 1, and the size of the solid-phase extraction microcolumn EC used is the same as that of Example 1, filled with 60-100 mesh carboxylic acid-type cation exchange resin for enriching cationic drug propranolol and metoprolol. The analysis process is as follows: connect the output terminal 3 of the electroosmotic pump into the reaction unit a to the input terminal 5 of the enrichment functional unit b, connect the terminal 6 of the enrichment functional unit b to the solid phase extraction microcolumn EC, and connect the output terminal of the EC to the microcolumn EC. The 11th end of the base tee of the column separation detection unit c, the ...

Embodiment 3

[0052] The injection, reaction, separation and detection and analysis system is combined and connected by an electroosmotic pump injection reaction unit a and a microcolumn separation detection unit c, and its flow path is shown in Figure 4 . In this example, electroosmotic pump P pressure and electrokinetic action are combined to drive the analysis solution and mobile phase to realize micro-column electrochromatographic separation. Due to the high porosity (50-60%) and low back pressure (0.1-0.4 MPa) of the high specific surface area monolithic column, the pressure provided by the electroosmotic pump P can meet the separation requirements of the electrochromatographic microcolumn. The inner diameter of the quartz tube electrochromatographic separation micro-column SC is 1-3 mm, and the column length is 10 cm. The integral column bed is synthesized by tetraethyl orthosilicate-hydrochloric acid-polyethylene glycol sol-gel method and fine quartz sand. Chromatographic Separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com