Bioactive glass nano powder and its biomimetic synthesis method

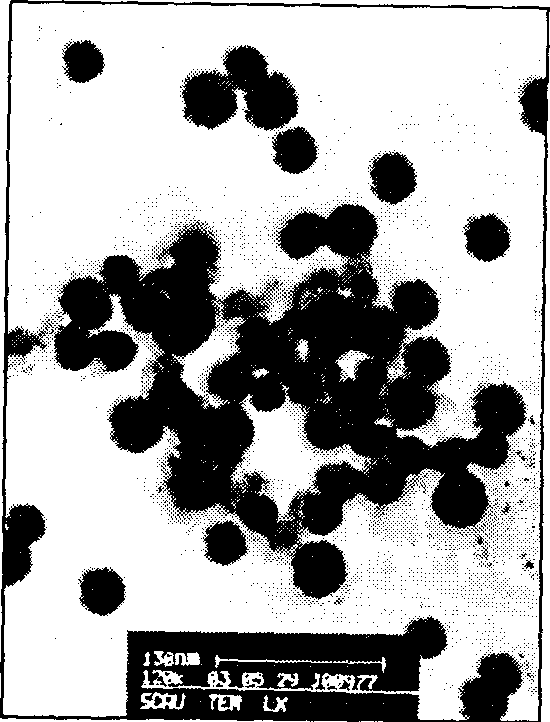

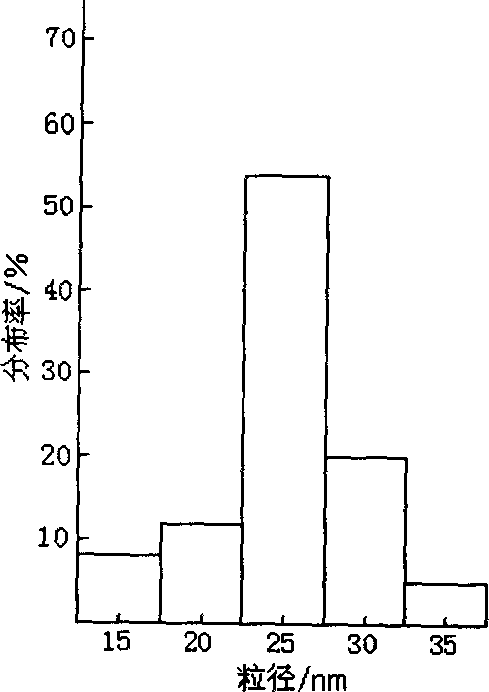

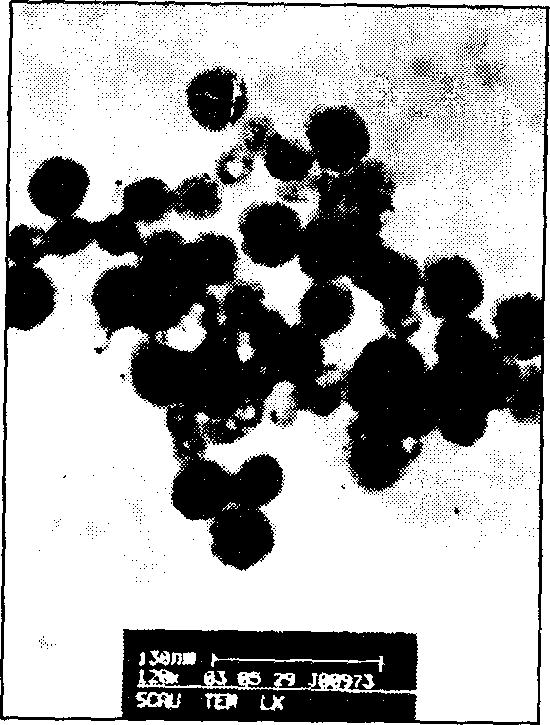

A technology of bioactive glass and nano-powder, which is applied in the field of biomimetic synthesis of bio-active glass nano-powder, can solve the problems of easy to form agglomeration, difficult to control powder particle size, wide particle distribution range, etc. The effect of small particle size and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of microemulsion organic template: add octylphenol-based polyoxyethylene ether (TritonX-100), co-surfactant and ammonium hydroxide aqueous solution (concentration 12.5%) or calcium nitrate aqueous solution (concentration 12.5%) in cyclohexane 0.6M), prepare the microemulsion of ammonium hydroxide solution and the microemulsion of calcium nitrate solution;

[0030] (2) Hydrolysis: adding tetraethyl orthosilicate (TEOS) and triethyl phosphate (TEP) to the microemulsion of ammonium hydroxide solution, a hydrolysis reaction occurs, and the hydrolysis reaction time is 30 to 60 minutes. (TEOS): triethyl phosphate (TEP): the weight ratio of ammonium hydroxide aqueous solution is 9: 1: 50;

[0031] (3) mixing: the microemulsion of the calcium nitrate solution configured in step (1) is added in the microemulsion obtained in step (2) by volume ratio 1: 1, and stirred for 60 minutes to obtain a mixed solution;

[0032] (4) aging: place the above mixed solution at ...

Embodiment 2

[0039] (1) Preparation of microemulsion organic template: add octylphenol-based polyoxyethylene ether (TritonX-100), co-surfactant and ammonium hydroxide aqueous solution (concentration 12.5%) or calcium nitrate aqueous solution (concentration 12.5%) in cyclohexane 0.6M), prepare the microemulsion of ammonium hydroxide solution and the microemulsion of calcium nitrate solution;

[0040] (2) Hydrolysis: adding tetraethyl orthosilicate (TEOS) and triethyl phosphate (TEP) to the microemulsion of ammonium hydroxide solution, a hydrolysis reaction occurs, and the hydrolysis reaction time is 30 minutes. ): triethyl phosphate (TEP): the weight ratio of ammonium hydroxide aqueous solution is 13: 1: 100;

[0041] (3) mixing: the microemulsion of the calcium nitrate solution configured in step (1) is added in the microemulsion obtained in step (2) by volume ratio 1: 1, and stirred for 80 minutes to obtain a mixed solution;

[0042] (4) aging: place the above mixed solution at room temp...

Embodiment 3

[0049] (1) Preparation of microemulsion organic template: add octylphenol-based polyoxyethylene ether (TritonX-100), co-surfactant and ammonium hydroxide aqueous solution (concentration 12.5%) or calcium nitrate aqueous solution (concentration 12.5%) in cyclohexane 0.6M), prepare the microemulsion of ammonium hydroxide solution and the microemulsion of calcium nitrate solution;

[0050] (2) Hydrolysis: adding tetraethyl orthosilicate (TEOS) and triethyl phosphate (TEP) to the microemulsion of ammonium hydroxide solution, a hydrolysis reaction occurs, and the hydrolysis reaction time is 30 minutes. ): triethyl phosphate (TEP): the weight ratio of ammonium hydroxide aqueous solution is 9: 1: 50;

[0051] (3) mixing: the microemulsion of the calcium nitrate solution configured in step (1) is added in the microemulsion obtained in step (2) by volume ratio 1: 1, and stirred for 60 minutes to obtain a mixed solution;

[0052] (4) aging: place the above mixed solution at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com