Method for preparing visible light catalyst of Nano crystal BiVO4 in high activity through ultrasound chemistry

A photocatalyst and ultrasonic chemistry technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of uneven microstructure, complex process, and energy consumption Time and other problems, to achieve the effect of short cycle, simple preparation process and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

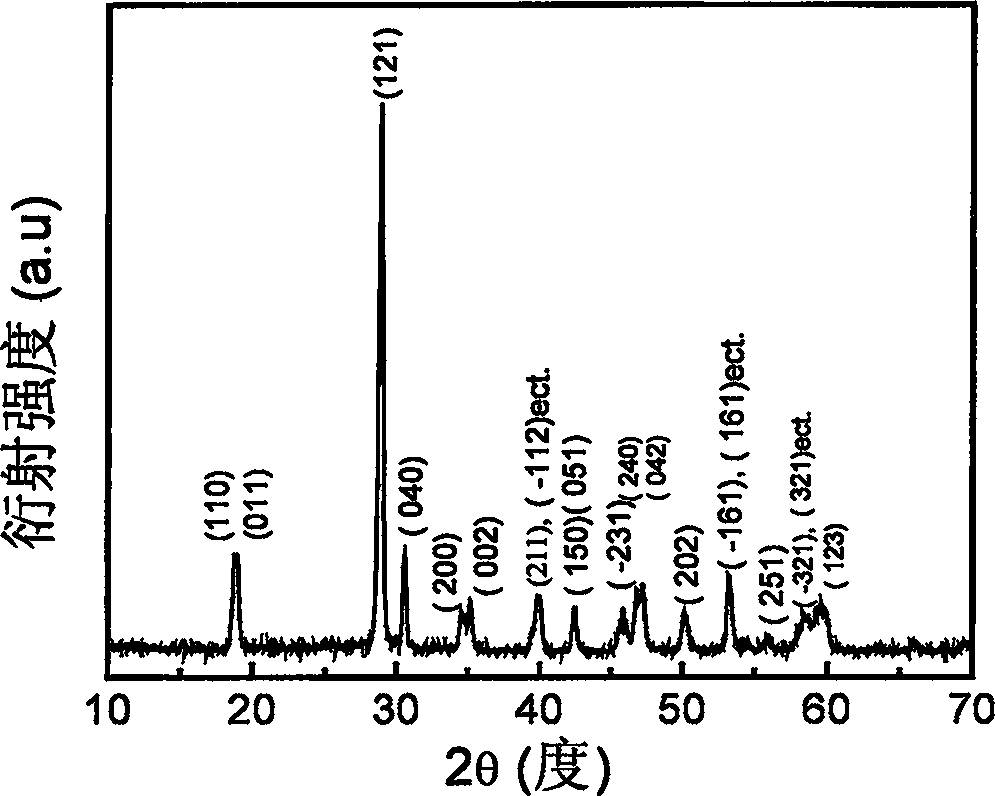

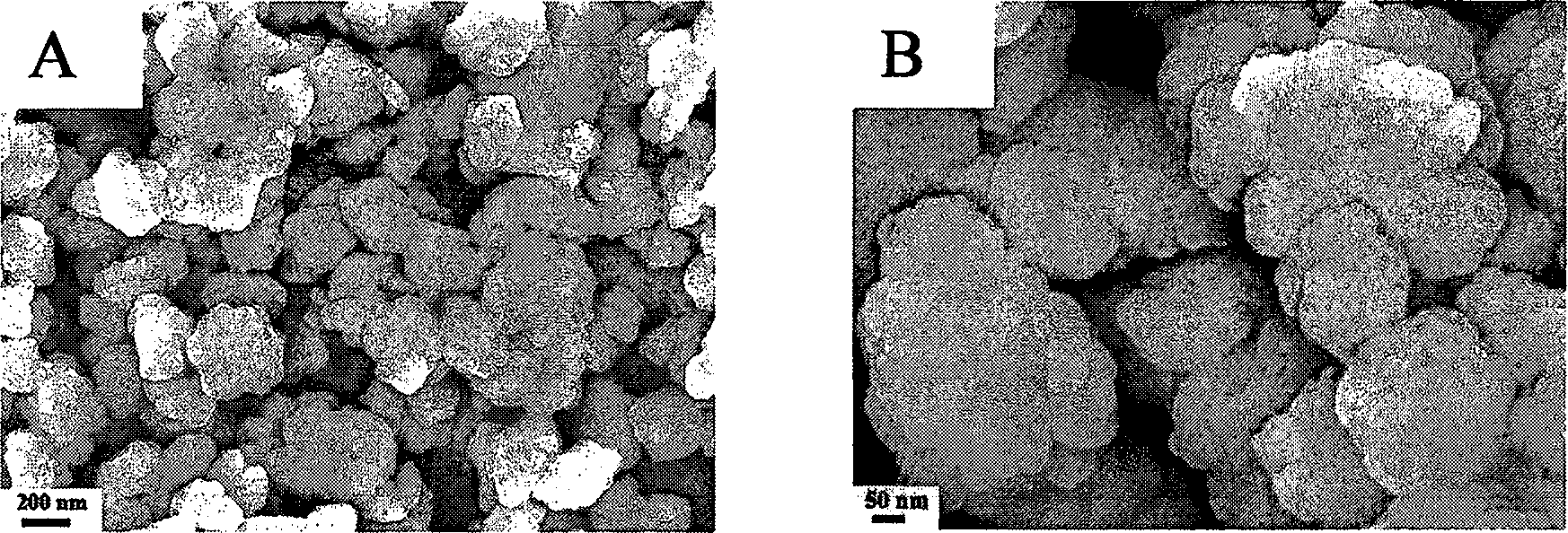

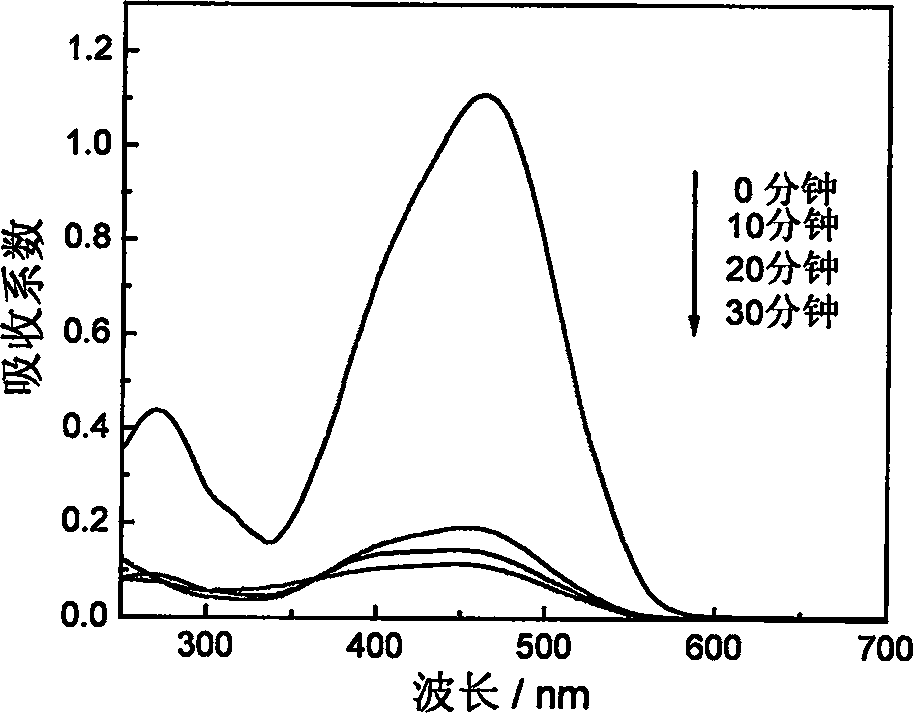

[0028] BiVO 4 Using Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 (Analytical pure) is synthesized as raw material, according to stoichiometric ratio, weighs 0.97g Bi(NO 3 ) 3 ·5H 2 O (analytical grade) was dissolved in 70 mL of water, and then 0.234 g of NH 4 VO 3 (analytical pure), stirring to form a yellow suspension precursor. Then immerse the ultrasonic probe in it for ultrasonic treatment. After comparative experiments, the diameter of the titanium alloy working probe is selected to be 0.6cm, the power of the ultrasonic wave is 500W, and the reaction time is 1h. After the reaction, the obtained yellow precipitate was filtered, washed three times with deionized water and absolute ethanol, and then dried at 80°C. like figure 1 , by XRD component analysis and Debye Scherer formula calculation, the monoclinic phase BiVO of about 50nm was obtained 4 Nanocrystalline. figure 2 Among them, A and B are typical scanning electron micrographs of different magnifications of samples...

Embodiment 2

[0032] BiVO 4 Use BiCl 3 and NH 4 VO 3 Synthesize as raw material, according to stoichiometric ratio, weigh 0.631g BiCl 3 (analytical pure) was dissolved in 70mL water, then added 0.2g polyethylene glycol (PEG20000), stirred for 30 minutes, then added 0.234g NH 4 VO 3 (analytical pure), stirring to form a yellow suspension precursor. Then immerse the ultrasonic probe in it for ultrasonic treatment, the ultrasonic power is 600W, and the reaction time is 1h. After the reaction, the obtained yellow precipitate was filtered, washed three times with deionized water and absolute ethanol, and then dried at 80°C. The product was determined to be monoclinic phase BiVO by XRD component analysis 4 , the particle size observed by an electron microscope is about 200nm, and the visible light degradation experiment result of wavelength λ>400nm is slightly lower than that of Example 1, and the degradation rate is 70%.

Embodiment 3

[0034] BiVO 4 Use BiCl 3 and NH 4 VO 3 Synthesize as raw material, according to stoichiometric ratio, weigh 0.631g BiCl 3 (analytical pure) was dissolved in 70mL of water, then added 0.2g cetyltrimethylammonium bromide (CTAB), stirred for 30 minutes, then added 0.234g NH 4 VO 3 (analytical pure), stirring to form a yellow suspension precursor. Then immerse the ultrasonic probe in it for ultrasonic treatment, the ultrasonic power is 600W, and the reaction time is 1h. After the reaction, the obtained yellow precipitate was filtered, washed three times with deionized water and absolute ethanol, and then dried at 60°C. XRD component analysis showed that the product was monoclinic phase BiVO 4 , the particle size of the product is about 500nm according to scanning electron microscope analysis. The visible light degradation experiment of methyl orange with wavelength λ>400nm shows that the visible light photocatalytic performance of the product prepared by using CTAB as surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com