Circulation desulfurization technology by ammonia-soda process

A desulfurization process, the technology of ammonia-soda method, applied in the field of ammonia-soda cycle desulfurization process, can solve the problems of increased operating costs, long chemical reaction time, high operating costs, etc., achieve fast replacement reaction speed, considerable economic benefits, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

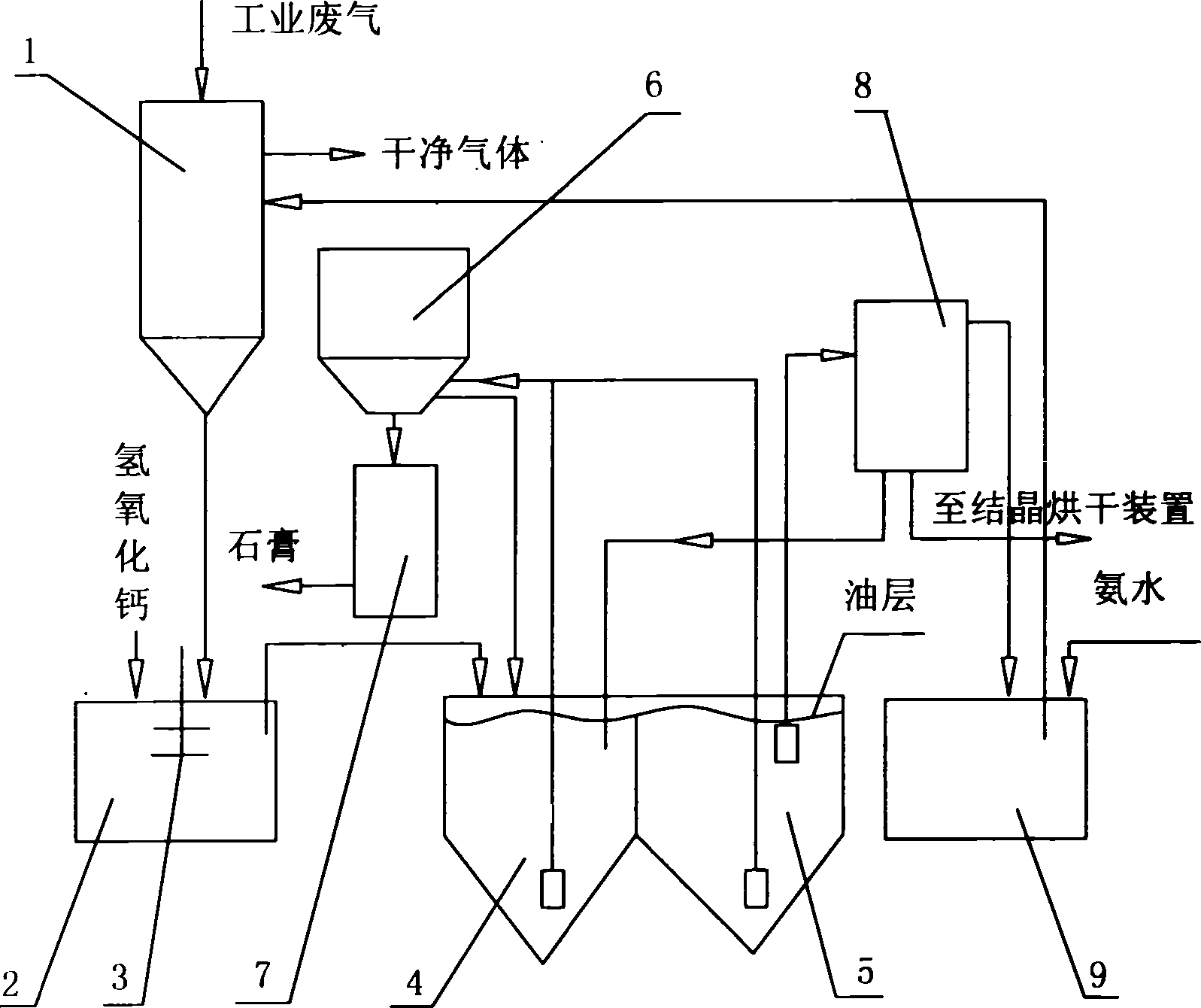

[0071] to combine figure 1 , an ammonia-alkali circulation desulfurization process, comprising the steps of:

[0072] (1), in absorber 1, ammoniacal liquor absorbs the sulfur dioxide in industrial waste gas, obtains ammonium sulfate solution under the presence of oxygen;

[0073] (2), above-mentioned gained ammonium sulfate solution enters displacement tank 2, reacts with calcium hydroxide solution, obtains calcium sulfate dihydrate and ammoniacal liquor. A stirring device 3 is installed in the replacement pool 2 .

[0074] The reaction liquid in step (2) enters the precipitation device for solid-liquid separation. The sedimentation device includes a thickening tank 4 and a transition tank 5, the thickening tank 4 is connected to the upper part of the transition tank 5; the reaction liquid in step (2) firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com