Preparation of natural-nanometer fiber-base tissue engineering cell stand

A nanofiber and tissue engineering technology, applied in medical science, prosthesis, etc., can solve the problems of complex process and high energy consumption, and achieve the effect of simple process, low energy consumption and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

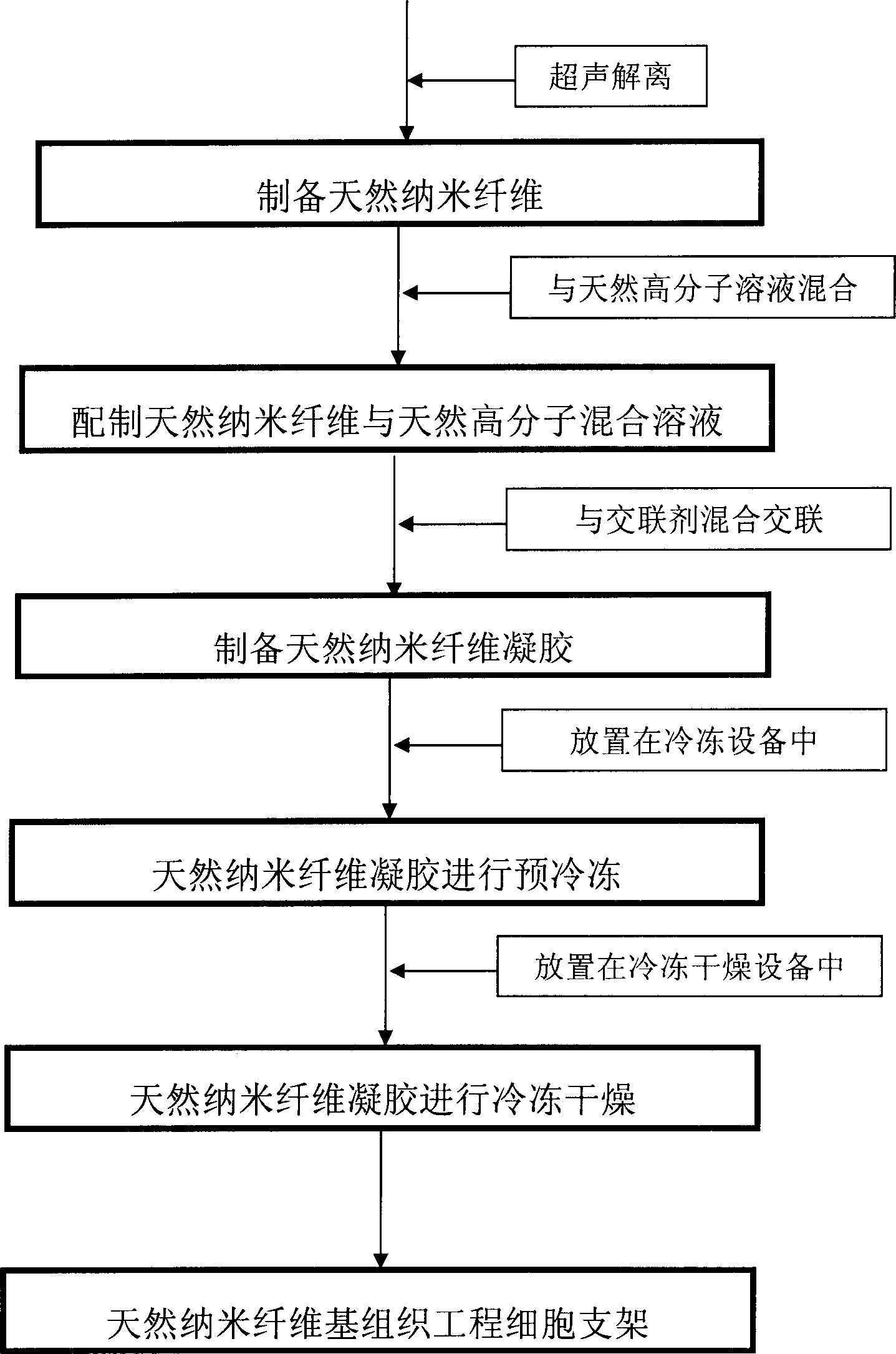

[0039] use as figure 1 and figure 2 device shown, follow the image 3 Preparation of natural spider silk nanofiber-based tissue engineering cell scaffolds using natural nanofibers: soak the spider silk in a beaker filled with ultrapure water; the power of the ultrasonic wave is 600 watts, the frequency is 20 kHz, and the probe of the ultrasonic generator Go deep into the beaker, ultrasonically dissociate for 2.5 hours to prepare natural spider silk nanofibers with a weight content of 60% of the gelatin solution and the gelatin solution, and add 10% by weight of the mixed solution. % glutaraldehyde is cross-linked to form natural spider silk nanofiber gel, which is left to stand at room temperature for 24 hours, then put into 10mol / liter glycine aqueous solution and left to stand at room temperature for 24 hours, and then the glycine-reacted gel is placed in Pre-freeze at -20°C for 4 hours, and then freeze-dry for 4 hours in a freeze dryer. The freeze-drying power is 3500 watt...

Embodiment 2

[0041] use as figure 1 and figure 2 device shown, follow the image 3 The process of preparing natural chitin nanofiber-based tissue engineering cell scaffold natural nanofibers: soak the natural chitin fibers in a beaker filled with ultrapure water; The probe goes deep into the beaker, ultrasonically dissociates for 2.5 hours, and prepares natural chitin nanofibers of 30 to 120 nanometers. The natural nanofibers with a weight content of 20% of the gelatin solution are mixed with the gelatin solution. 5% formaldehyde is cross-linked to form natural chitin nanofiber gel, which is left to stand at room temperature for 12 hours, then placed in a 5mol / liter glycine aqueous solution and left to stand at room temperature for 12 hours, and then the glycine-reacted gel is placed in- Pre-freezing at 20°C for 14 hours, and then freeze-drying in a freeze dryer for 14 hours. The freeze-drying power is 3500 watts, and the condenser temperature is -85°C. The natural chitin nanofiber-base...

Embodiment 3

[0043] use as figure 1 and figure 2 device shown, follow the image 3 The process of preparing natural silk nanofiber-based tissue engineering cell scaffold natural nanofibers: soak the silk reeled from silkworm cocoons in a beaker filled with ultrapure water; the power of the ultrasonic wave is 600 watts, the frequency is 20 kHz, The probe of the ultrasonic generator goes deep into the beaker, and ultrasonic cavitation is performed for 1.5 hours to prepare natural silk nanofibers with a weight content of 10% of the chitosan solution and the chitosan solution. , add the carbodiimide that weight content is 2% of mixed solution to carry out cross-linking and form natural silk nanofiber gel, stand still at room temperature for 12 hours, put into 2mol / liter aqueous solution of glycine subsequently and stand at room temperature for 1 hour, then The gel after glycine reaction was pre-frozen at -20°C for 10 hours, and then freeze-dried in a freeze dryer for 10 hours. The freeze-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com