Titanium anode coated with iridium possessing high cerium content and high oxygen separated activity

A technology of titanium anode and oxygen evolution, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., to achieve the effect of low oxygen evolution potential of electrodes, fine structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

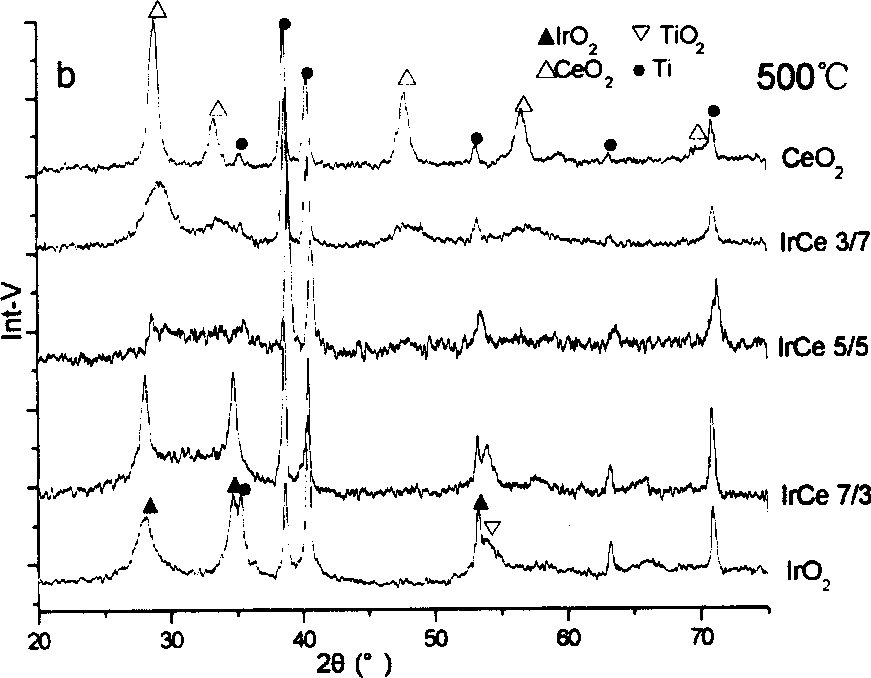

Embodiment 1

[0022] After degreasing the 20mm×40mm titanium plate (Ta1) with alkaline washing powder, put it in a 10% (mass fraction) oxalic acid solution, boil it for 2 hours, take it out, rinse it with distilled water, dry it, and put it in an ethanol solution for later use. Weigh cerium nitrate (Ce(NO) according to Table 1 3 ) 3 ·6H 2 O) and chloroiridic acid (H 2 IrCl 6 ) was dissolved in an appropriate amount of n-butanol, and then the two solutions were mixed with each other. The above coating solutions with different ratios were evenly coated on the spare titanium plate, then dried, sintered at 500° C. for 10 minutes, and then taken out and cooled to room temperature. Recoat, sinter, and cool until all solution is applied. Finally, after annealing at 500 °C for 1 h, different molar contents of IrO can be obtained. 2 -CeO 2 Oxide coated anode. Its oxygen evolution potential is shown in Table 1. It can be seen that when the coating contains CeO 2 , the oxygen evolution poten...

Embodiment 2

[0025] After degreasing the 20mm×40mm titanium plate (Ta1) with alkaline washing powder, put it in a 10% (mass fraction) oxalic acid solution, boil it for 2 hours, take it out, rinse it with distilled water, dry it, and put it in an ethanol solution for later use. Weigh cerium nitrate (Ce(NO) according to Table 2 3 ) 3 ·6H 2 O), chloroiridic acid (H 2 IrCl 6 ) and SnCl 2 ·2H 2O is dissolved in an appropriate amount of n-butanol, and then mixed with each other. The above-mentioned coating solution was evenly coated on a spare titanium plate, dried, and sintered at 500° C. for 10 minutes, then taken out and cooled to room temperature. Recoat, sinter, and cool until all solution is applied. Finally, CeO can be obtained by annealing at 500 °C for 1 h. 2 -IrO 2 -SnO 2 Oxide coated anode. The oxygen evolution potential of the obtained titanium anode is shown in Table 2. It can be seen that the oxygen evolution potential ratio is completely determined by the IrO 2 The ox...

Embodiment 3

[0028] After degreasing the 20mm×40mm titanium plate (Ta1) with alkaline washing powder, put it in a 10% (mass fraction) oxalic acid solution, boil it for 2 hours, take it out, rinse it with distilled water, dry it, and put it in an ethanol solution for later use. Weigh cerium nitrate (Ce(NO) according to Table 2 3 ) 3 ·6H 2 O), chloroiridic acid (H 2 IrCl 6 ) was dissolved in an appropriate amount of n-butanol, and then mixed with each other. Weigh a certain amount of ruthenium chloride, tantalum pentachloride, butyl titanate (Ti(C 4 H 9 O) 4 ), stannous chloride, antimony nitrate, manganese chloride, cobalt chloride, nickel nitrate and other salts are respectively dissolved in dehydrated alcohol (components are shown in Table 3) successively, and citric acid and ethylene glycol are added dropwise dropwise respectively The mixed solution, after fully stirring, was prepared to form RuO 2 , Ta 2 O 5 , TiO 2 , SnO 2 , Sb 2 O 3 , MnO 2 , Co 3 O 4 and NiO 2 etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com