Composite stand materials of polylactic acid base/nano-hydroxy-apatite and its production

A nano-hydroxyapatite, polylactic acid-based technology, used in medical science, prostheses, bone implants, etc., can solve the problems of simple chemical structure and uneven dispersion of nano-hydroxyapatite, and achieve good compatibility. The effect of stability and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

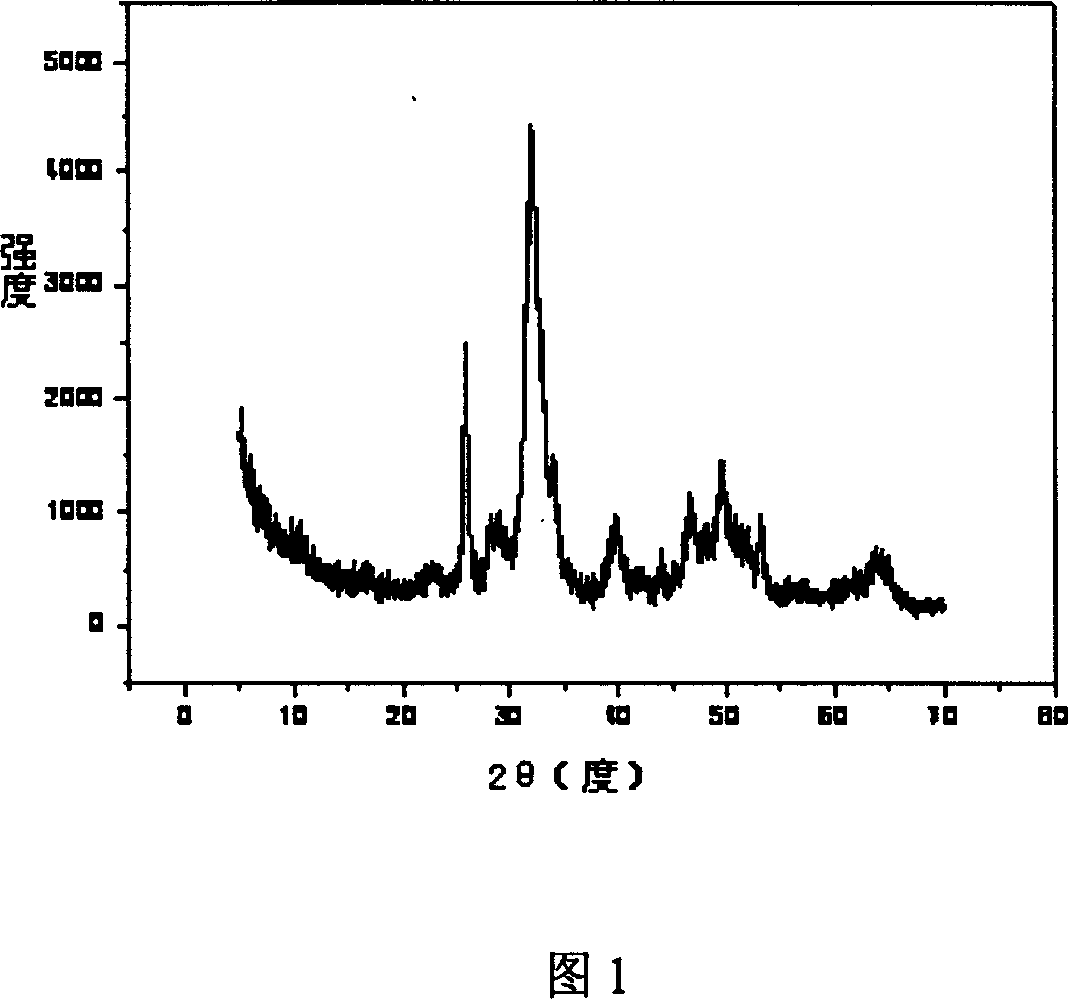

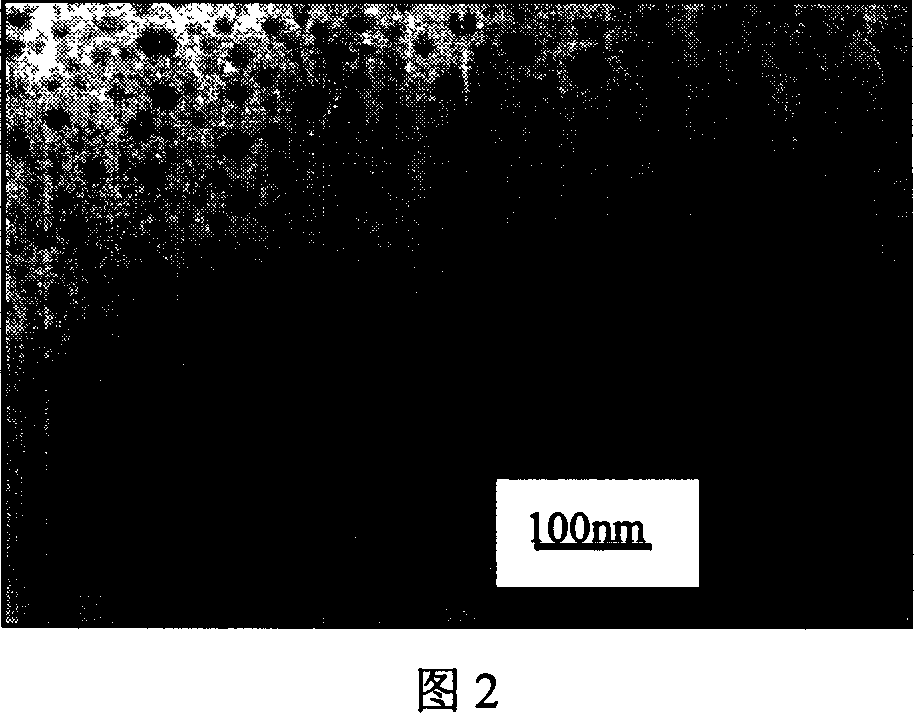

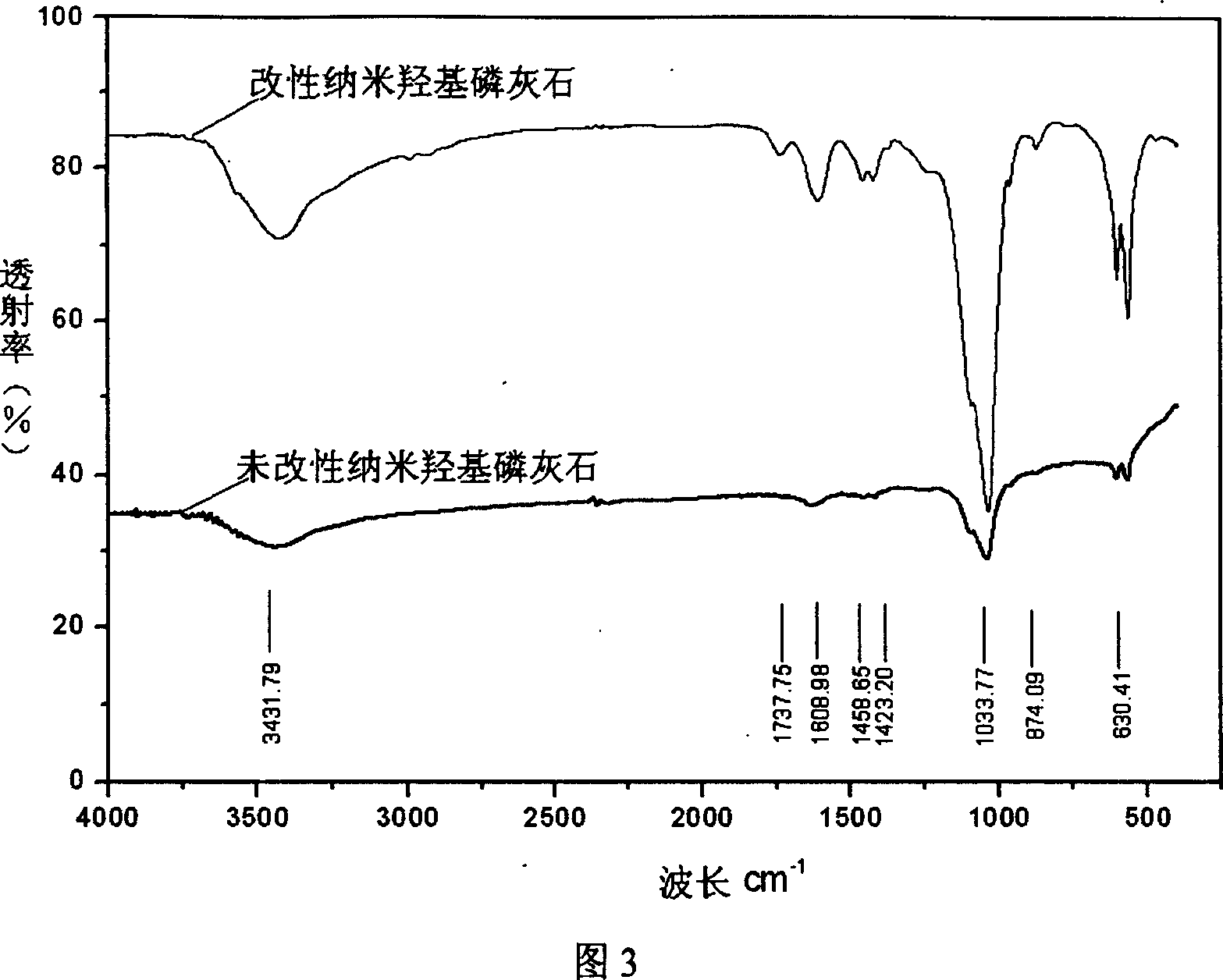

[0035]Example 1. First, calcium nitrate and diammonium hydrogen phosphate were weighed according to Ca / P=1.67 and each prepared into aqueous solutions. The aqueous solution of diammonium hydrogen phosphate was dropped into the aqueous solution of calcium nitrate, and the temperature was controlled at room temperature and the reaction system PH=10-11, make it chemically react to produce colloidal HA precipitate, after the reaction is completed, add PEG2000 aqueous solution with a weight concentration of 0.1% as a surfactant. The nano-hydroxyapatite is obtained by aging at room temperature for 10-20 hours, repeatedly filtering, washing, and then drying. Put the prepared xylene solution of nano-hydroxyapatite into a device with condensation, reflux, nitrogen protection, and stirring, and then add dropwise the xylene solution of lactide, lactide and nano-hydroxyphosphorus The mass ratio of graystone is 1:1, and the reaction is carried out at 120°C for 16 hours. After the reaction, the...

Embodiment 2

[0036] Example 2. The synthesis and modification of nano-hydroxyapatite are the same as in Example 1. Lactide and glycolide were reacted with stannous octoate as a catalyst at 140°C for 10 hours at a molar ratio of 85:15 to obtain a polylactic acid-glycolic acid copolymer (PLGA) with a molecular weight of 130,000. The above-mentioned PLGA and the modified nano-hydroxyapatite are weighed at a weight ratio of 100:5, NaCl is 1% of the weight of PLGA, and dissolved in a dioxane-water solution system with a volume ratio of 87 / 13. PLGA The PLGA(85 / 15) / HA composite porous tissue engineering scaffold was obtained by initializing at -10°C for 2h and then curing for 10min, freeze-drying for 72h, and annealing at 30°C for 6h. The concentration was 9%.

Embodiment 3

[0037] Example 3. The synthesis and modification of nano-hydroxyapatite and the synthesis of PLGA (75 / 25) are the same as in Example 1. The above-mentioned PLGA (75 / 25) and modified nano-hydroxyapatite were weighed at a weight ratio of 100:5, and dissolved in a dioxane-water solution system with a volume ratio of 87 / 13. The concentration of PLGA was 9%, using a step-by-step initialization method to first roughen at 5°C for 1 hour, then at 0°C for 2 hours, solidify for 30 minutes, freeze-dry for 72 hours, and anneal at 30°C for 6 hours to obtain a PLGA / HA composite porous scaffold Engineering stent, the SEM picture is shown in Figure 5(a).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com