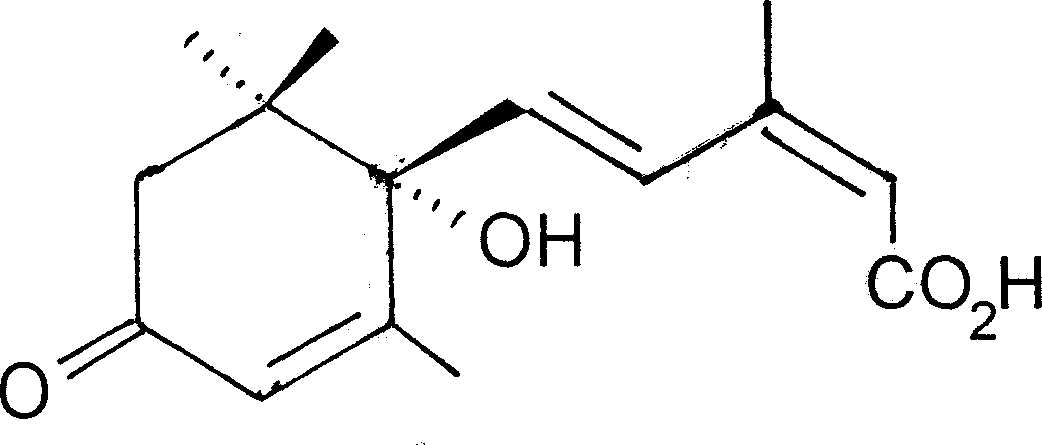

Method for separating and extracting abscisic acid from fermented liquid by ionic exchanging and reversed phase chromatography

A technology of reverse phase chromatography and ion exchange, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of high price of natural abscisic acid, affecting the research of natural abscisic acid, affecting the application of natural abscisic acid, etc., to achieve The extraction method is simple and reasonable, the method is simple, and the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

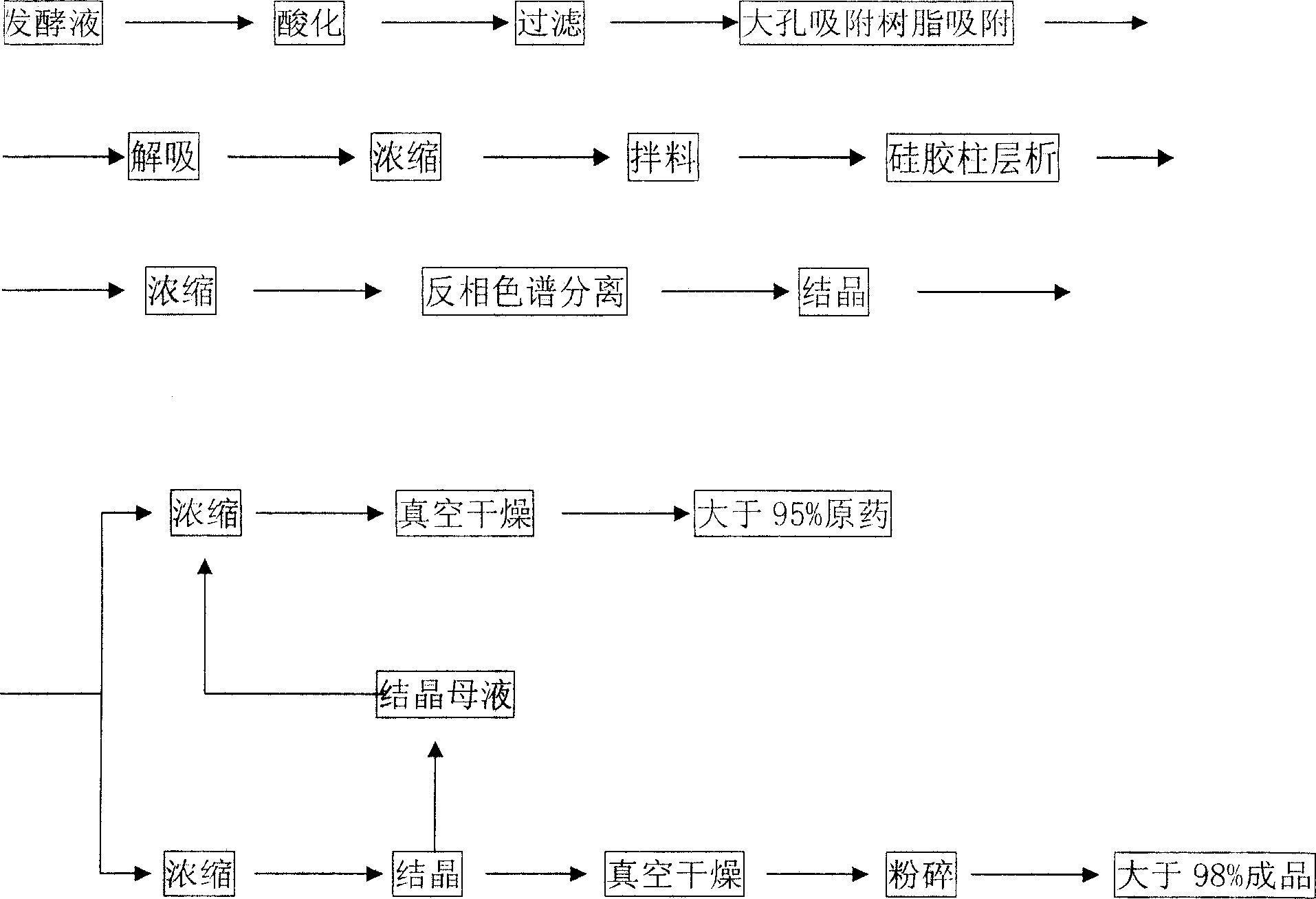

Method used

Image

Examples

Embodiment 1

[0032] 1000mL fermentation medium composition: 5.0% dextrin, 0.3% wheat bran, 0.02% ethylene glycol, 2.0% glucose, 3.0% sucrose, 1.0% bean cake powder, 0.01% dipotassium hydrogen phosphate, 0.05% magnesium sulfate.

[0033] Divide 1200mL of the above medium into four 1000mL Erlenmeyer flasks, 300mL in each bottle, sterilize at 120°C for 30 minutes, inoculate the spore suspension of the activated abscisic acid high-yielding strain Botrytis cinerea TBI-9 after cooling, and inoculate at 23-29°C under fermentation. Oscillation speed 150rpm, amplitude 20cm. The fermentation time is 8-12 days, and the concentration of natural abscisic acid reaches 0.14%.

[0034] Take 1000 grams of fermentation broth (the content of natural abscisic acid is 1.431 grams), add 3N sulfuric acid solution to adjust the Ph to 2.0-5.0, and carry out acidification treatment for 30 minutes. The fermented broth after acidification is centrifuged at room temperature for 10 minutes at a centrifugal speed of 5...

Embodiment 2

[0040] The preparation method of fermented liquid is the same as Example 1, get 1000 grams of fermented liquid (natural abscisic acid content is 1.410 grams), add 9.0 liters of water, make the concentration of natural abscisic acid in the liquid be 0.014%, replace original fermented liquid with this solution and extract separate. Add 3N hydrochloric acid solution to adjust the Ph to 2.0-5.0, centrifuge at 5000-9000 rpm for 10 minutes at room temperature, and collect the supernatant. The centrifuged supernatant was in contact with 200-1000 grams of 101 macroporous cation exchange resin for 1 hour, and then washed with 1000-5000 mL of 40-85% methanol for 30 minutes, and the methanol solution containing natural abscisic acid was collected. The abscisic acid content is 1.387 grams.

[0041] The eluting methanol liquid was distilled under reduced pressure on a Buchi R-3000 rotary distillation device, the vacuum degree was maintained at 0.06-0.09Mpa, the temperature of the water ba...

Embodiment 3

[0044] The preparation method of fermented liquid is the same as embodiment 1, gets 3000 grams of fermented liquid, and natural abscisic acid content is 4.248 grams in fermented liquid. Concentrate under reduced pressure to 1000 g, so that the concentration of the fermented liquid is 0.423%, and use this solution to replace the original fermented liquid for extraction and separation. The extraction and separation operation is basically the same as in Example 1. Finally, 1.006 grams of natural abscisic acid with a purity of 95.8% and 2.623 grams of natural abscisic acid crystals with a purity of 99.1% were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com