Method for preparing dielectric crystal of calcium tungstate rapidly

A calcium tungstate mesocrystalline and fast technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as unfavorable large-scale production, complex reaction devices and preparation processes, and avoid the rapid growth of crystal nuclei Large, achieve directional self-assembly, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Add 14.02mL of n-octane, 1.15mL of n-butanol, 1.3g of cetyltrimethylammonium bromide (CTAB) in a 50mL Erlenmeyer flask, and add 1.90mL of 0.5mol l -1 Aqueous calcium chloride solution. Stir for 30 minutes to form a homogeneous and transparent calcium ion microemulsion.

[0021] 2) Add 14.02mL of n-octane, 1.15mL of n-butanol and 1.3g of cetyltrimethylammonium bromide (CTAB) in a 50mL Erlenmeyer flask, and add 1.90mL of 0.5mol·l -1 Sodium tungstate aqueous solution. Stir for 30 minutes to form a homogeneous and transparent tungstate ion microemulsion.

[0022] 3) The above two microemulsions respectively containing calcium chloride and sodium tungstate were rapidly mixed at 25° C., continued to stir for 10 minutes, and the reaction was completed. Centrifuge, wash with deionized water and absolute ethanol several times, and vacuum dry at 60°C for 6 hours to obtain calcium tungstate mesocrystals.

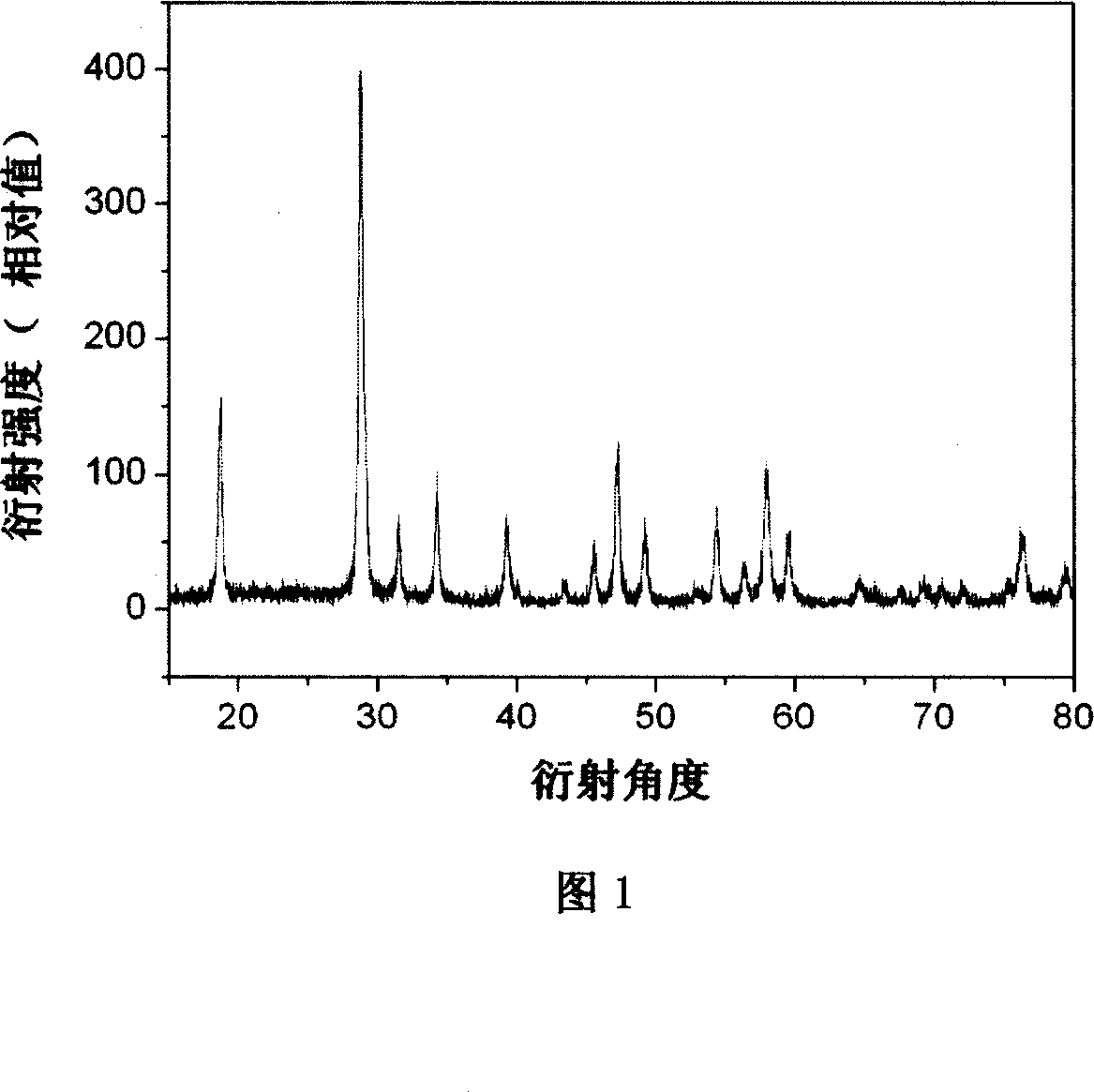

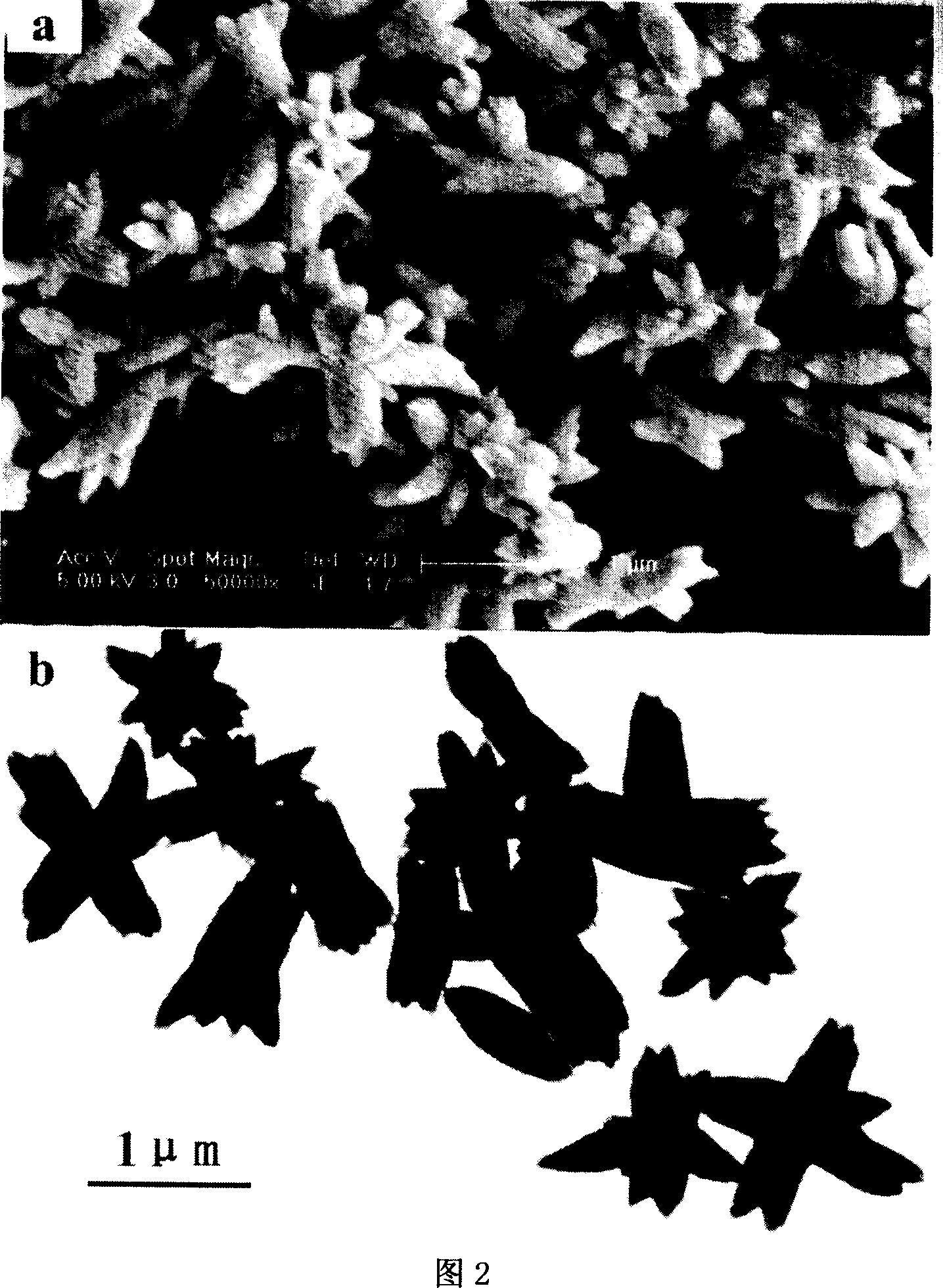

[0023] Fig. 1 is the X-ray diffraction diagram of the obtained calci...

Embodiment 2

[0025] 1) Add 13.66mL of n-octane, 1.05mL of n-butanol and 1.15g of cetyltrimethylammonium bromide (CTAB) in a 50mL Erlenmeyer flask, and add 1.48mL of 0.15mol·l -1 Calcium nitrate aqueous solution. Stir for 30 minutes to form a homogeneous and transparent calcium ion microemulsion.

[0026] 2) Add 13.66mL of n-octane, 1.05mL of n-butanol, 1.15g of cetyltrimethylammonium bromide (CTAB) in a 50mL Erlenmeyer flask, and add 1.48mL of 0.15mol·l -1 Sodium tungstate aqueous solution. Stir for 30 minutes to form a homogeneous and transparent tungstate ion microemulsion.

[0027] 3) The above two microemulsions respectively containing calcium nitrate and sodium tungstate were rapidly mixed at 25° C., and the stirring was continued for 10 minutes, and the reaction was completed. Centrifuge, wash with deionized water and absolute ethanol several times, and vacuum dry at 60°C for 6 hours to obtain calcium tungstate mesocrystals.

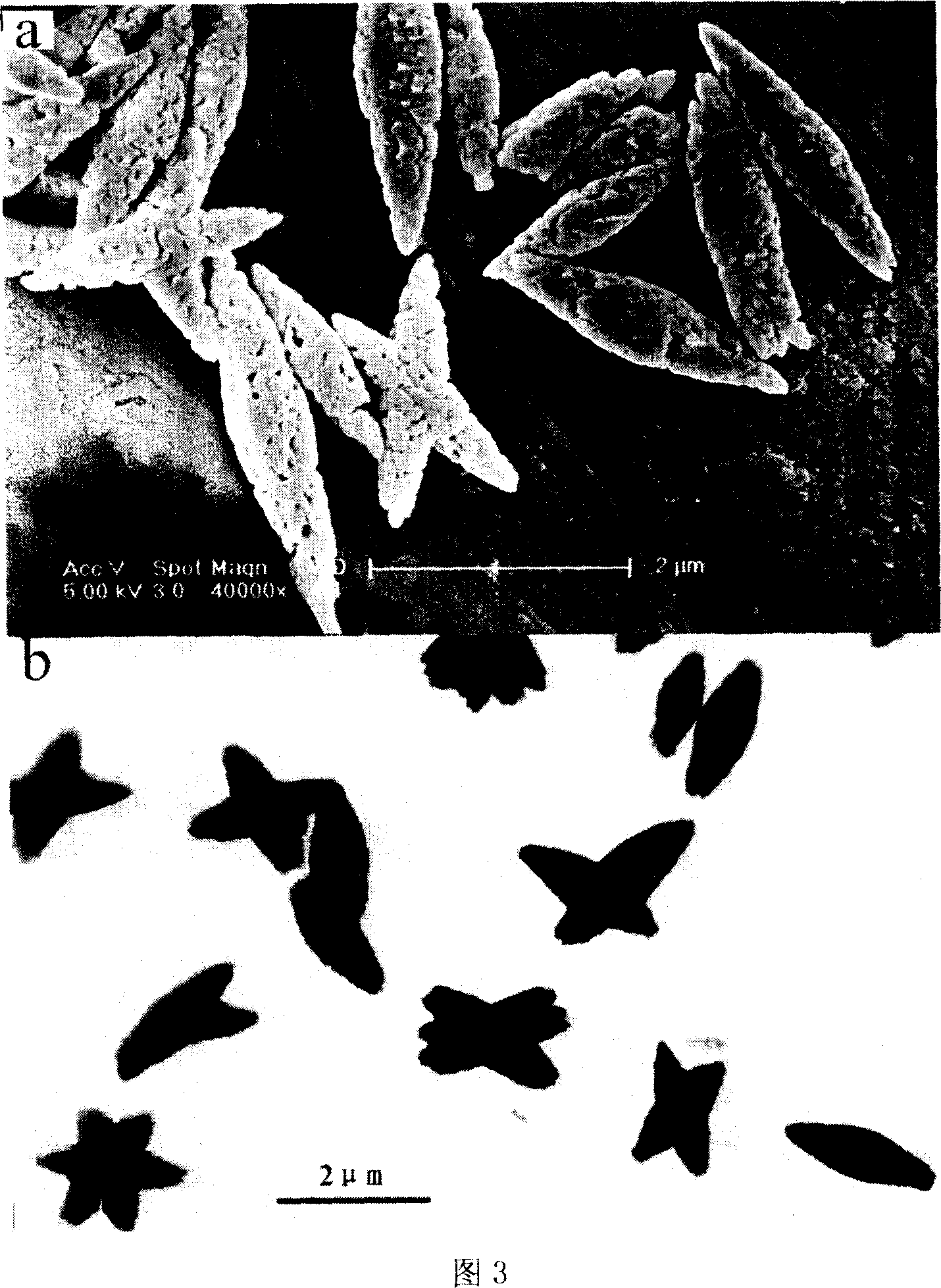

[0028] Fig. 3 is a scanning electron micrograph and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com