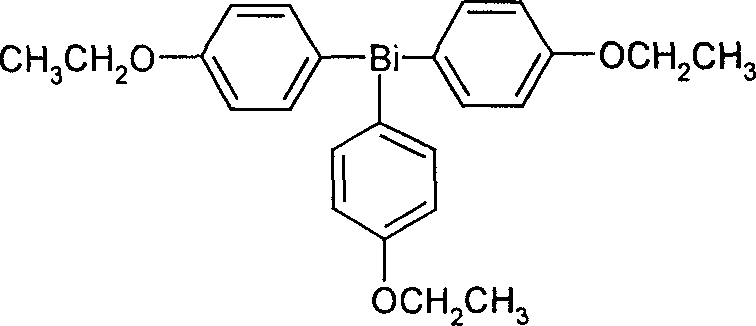

Preparing process of tri (4-ethoxy phenyl) bismuth

A technology of ethoxyphenyl and phenetole, which is applied in the direction of bismuth organic compounds, can solve the problems of long reaction time, poor safety, and high cost, and achieve the effects of short reaction time, increased yield, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

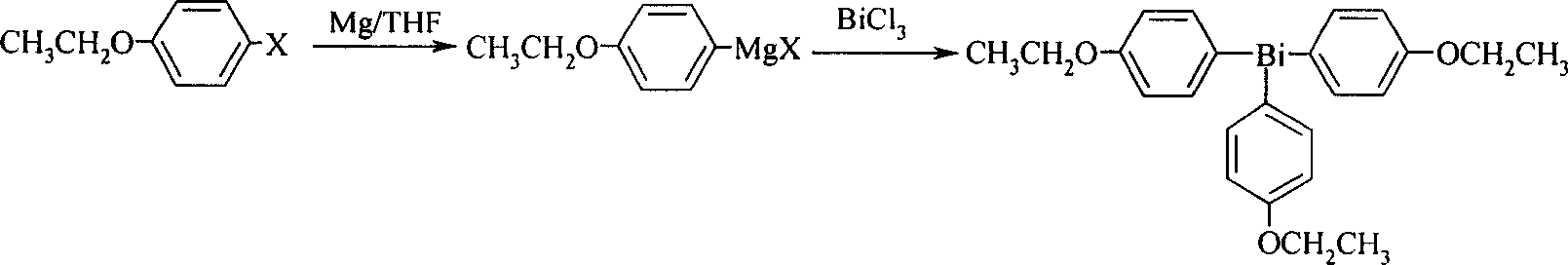

Method used

Image

Examples

Embodiment 1

[0025] In a 500ml four-neck flask equipped with heating, stirring, thermometer, reflux condenser, and drying tube, add 0.45mol (10.8g) magnesium powder, 20ml tetrahydrofuran (THF), 0.3g bromoethane, introduce nitrogen, and nitrogen atmosphere Under stirring, 0.05g iodine was added to initiate the reaction, and a mixture of 0.4mol (62.7g) 4-chlorophenetole and 50ml THF was slowly added dropwise within 1.5 hours, heated to reflux, and reacted for 5 hours. Cool to room temperature, add dropwise a mixture of 0.13mol (41.2g) bismuth trichloride and 120ml THF within 1 hour, heat up to reflux, react for 3 hours, cool to room temperature, and pour the reaction solution into 200ml of 15% hydrochloric acid solution. Add 100ml of benzene for extraction, wash the separated organic phase with water until neutral, dry over anhydrous sodium sulfate, filter, evaporate the filtrate to remove the solvent, and obtain the crude product of tris(4-ethoxyphenyl)bismuth, mix it with 550ml of benzene / e...

Embodiment 2

[0027] Add respectively 0.416mol (10g) magnesium powder, 20ml tetrahydrofuran (THF), 0.5g bromopropane in a 500ml four-necked flask with a thermometer, a reflux condenser, and a drying tube, introduce nitrogen, and stir under a nitrogen atmosphere. 0.1 g of liquid bromine was added to initiate the reaction, and a mixture of 0.4 mol (80.4 g) of 4-bromophenetole and 100 ml of THF was slowly added dropwise within 1 hour, heated to reflux, and reacted for 3 hours. Cool to room temperature, drop in 0.12mol (38g) bismuth trichloride and 100ml THF mixed solution within 40 minutes, heat up to reflux, react for 2.5 hours, cool to room temperature, pour the reaction solution into 200ml 20% sulfuric acid solution, add 100ml of benzene is extracted, and the separated organic phase is washed with water to neutrality, dried over anhydrous sodium sulfate, filtered, and the filtrate is evaporated to remove the solvent to obtain the crude product of tris(4-ethoxyphenyl)bismuth, which is washed ...

Embodiment 3

[0029] Add 0.41mol (9.8g) of magnesium powder, 20ml of tetrahydrofuran (THF), and 0.4g of bromoethane into a 500ml four-necked flask equipped with heating, stirring, thermometer, reflux condenser, and drying tube, introduce nitrogen, and Stir, add 0.05g of iodine to initiate the reaction, slowly drop in a mixture of 0.4mol (80.4g) 4-bromophenetole and 120ml THF within 1.5 hours, heat up to reflux, and react for 4.5 hours. Cool to room temperature, add dropwise the mixed solution of 0.13mol (41.2g) bismuth trichloride and 120ml THF within 40 minutes, heat up to reflux, react for 1.5 hours, cool to room temperature, and pour the reaction solution into 200ml 20% sulfuric acid solution, Add 150ml of benzene for extraction, the separated organic phase is washed with water to neutrality, dried over anhydrous sodium sulfate, filtered, and the filtrate is evaporated to remove the solvent to obtain the crude product of tris(4-ethoxyphenyl)bismuth, which is mixed with 600ml of benzene / et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com