Method of manufacturing light transmission tubes

a technology of light transmission tubes and manufacturing methods, which is applied in the direction of waveguides, fibre light guides, instruments, etc., can solve the problems of difficult to manufacture light transmission tubes in the above manner, electric shock or electric leakage, and low brightness of the circumferential surface area of light transmission tubes, so as to reduce possible light loss, high brightness, and directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

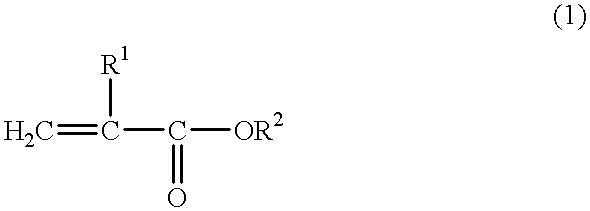

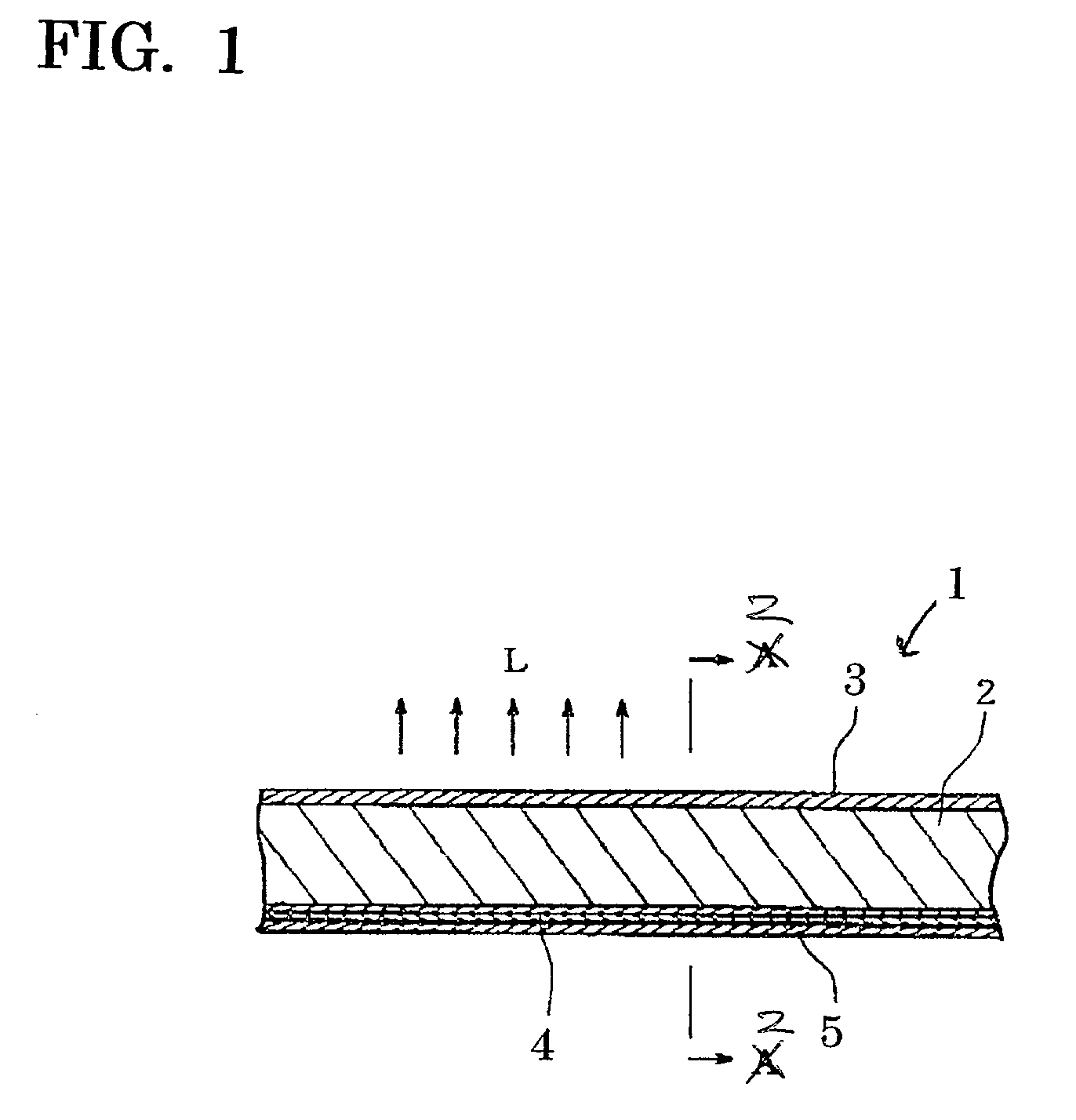

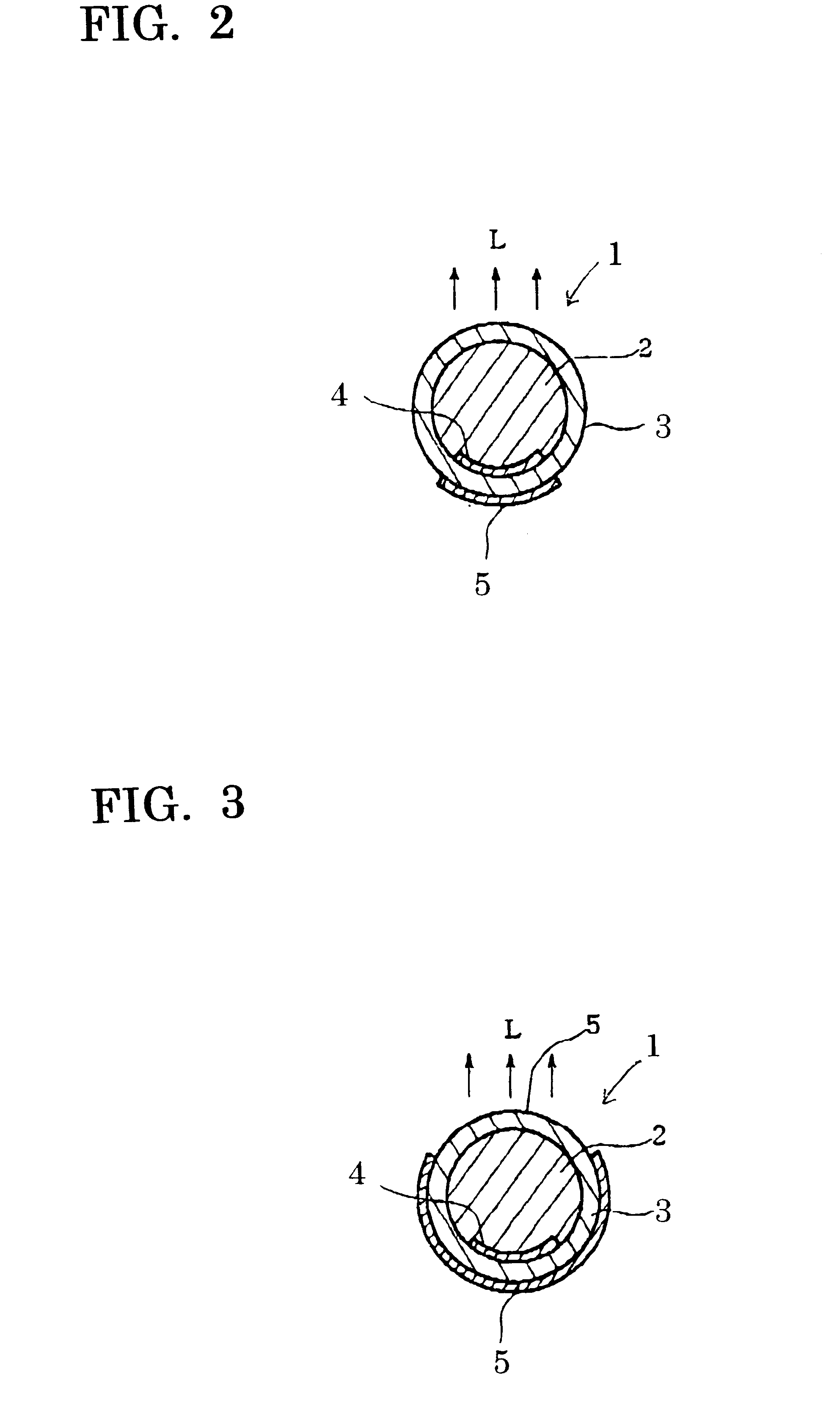

[0085] 60 parts by weight of MMA (methyl methacrylic acid), 40 parts by weight of LMA (lauryl methacrylic acid), and 0.05 parts by weight of BPO (benzol peroxide) were mixed together to form a monomer solution (a liquid material for forming the core section 2, having a specific gravity of 0.92). Then, 0.15 parts by weight of light scatterring particles, which may be silicon resin particles (made by Toshiba Silicon Co., Ltd.) having an average particle size of 7 .mu.m and a specific gravity of 0.92, or may be polystyrene resin particles (made by Sekisui Chemical Products Co., Ltd.) having an average particle size of 10 .mu.m and a specific gravity of 1.06, were added into 100 parts by weight of the monomer solution. Afterwards, the monomer solution containing the light scatterring particles was poured into an FEP tube having an outer diameter of 6 mm and a length of 1.5 m. Subsequently, both ends of the FEP tube were sealed up and the tube itself was kept still in a horizontal positi...

example 2

[0090] A light transmission tube was manufactured in the same manner as in Example 1. The brightness on one side surface area of the light transmission tube obtained in Example 2 was measured in the same manner as in Example 1, with the use of a LED red lamp as a light source (an applied voltage was 2 V, an electric current was 20 mA, an electric power was 0.04 W). The light transmission tube obtained in Example 2 was compared with another light transmission tube (Comparative Example 2) which involves the use of a light reflective tape (consisting of a polyvinyl chloride resin containing a white color pigment, the tape itself being coated with an adhesive agent) bonded on the outer surface of the clad so as to cover the reflecting layer. The results of the measurements of the two light transmission tubes are shown in the following Table 2.

2 TABLE 2 Added Amount Measurement Position (Parts (A distance from a light introducing end Dispersed by position on a light transmission tube) Pa...

example 3

[0092] A three-color extrusion molding machine having three crew sections was used, which is capable of extruding at the same time a core formation material, a clad formation material and a light reflecting material. The core formation material, the clad formation material consisting of an acryl polymer, a reflecting layer formation material obtained by dispersing fifteen weight percent of a titan oxide in an acryl polymer (which is the same as the acryl polymer for forming the clad), are at the same time introduced into an inlet mouth adaptor on the three-color extrusion molding machine, thereby simultaneously forming a solid cylindrical rod having a diameter of 6 mm, a belt-like white color reflecting layer having a width of 1.5 mm and a thickness of 0.01-0.02 mm (which is formed on the outer surface of the solid cylindrical rod), and a tubular clad coverring the rod and the reflecting layer, thus producing a cylindrical light transmission tube. The brightness on one side surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com