Wavelength tunable laser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

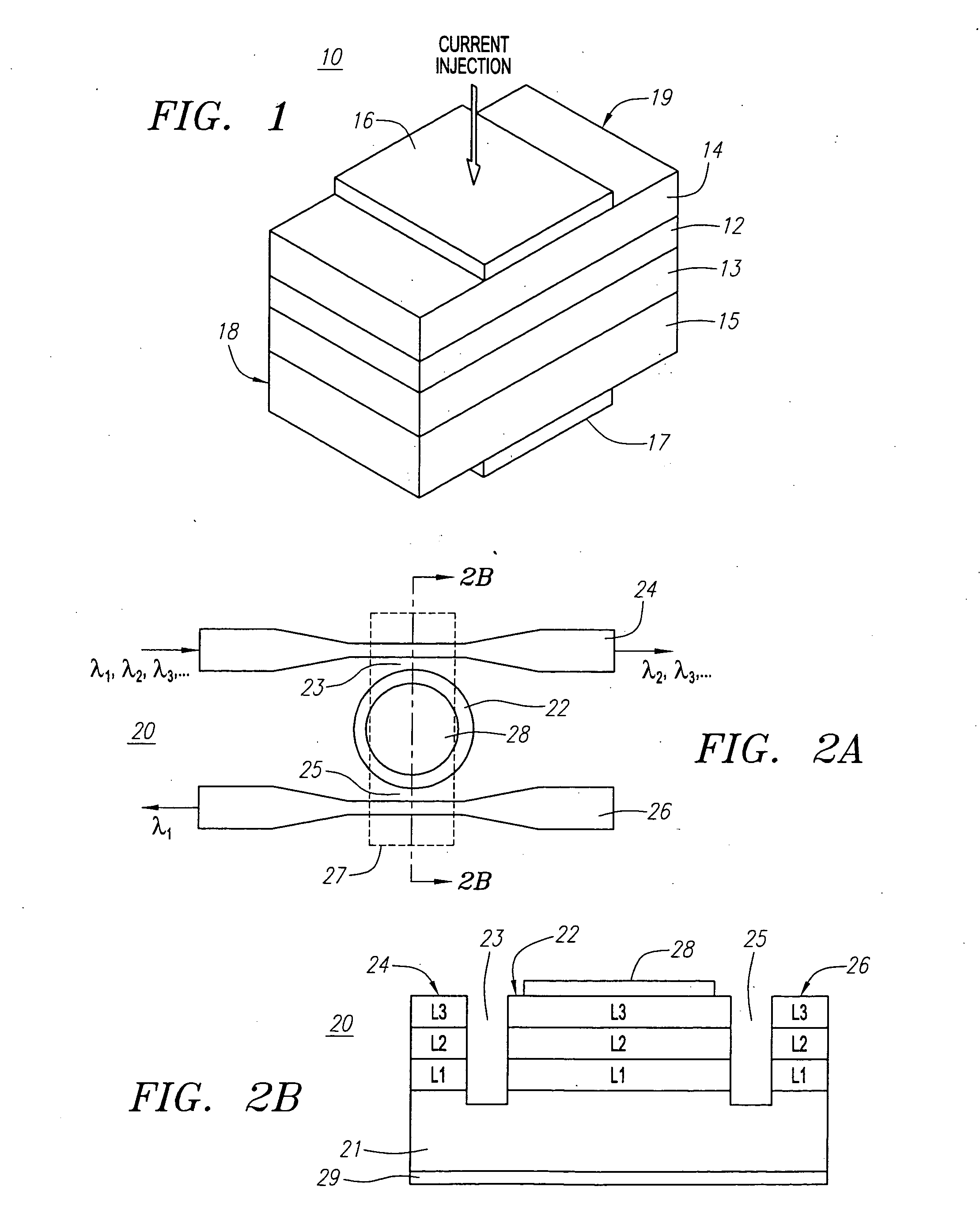

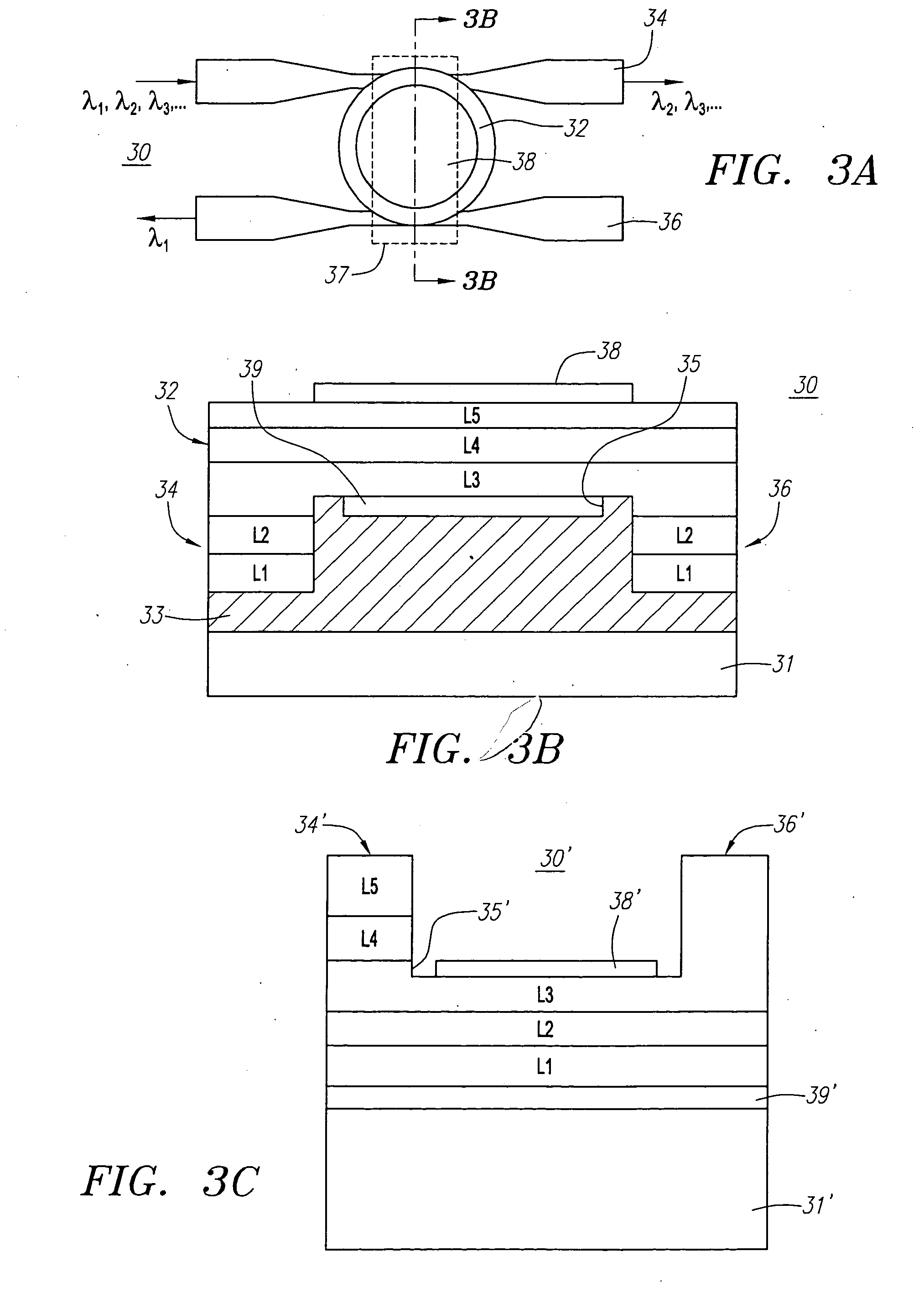

Referring in detail to the figures, a wavelength tunable laser of the present invention, as shown, combines a semiconductor laser diode with a waveguide-coupled optical resonator. The waveguide-coupled optical resonator serves as a wavelength selective, external cavity to realize a tunable laser by applying voltage or injecting current to change the resonance wavelength of the resonator(s).

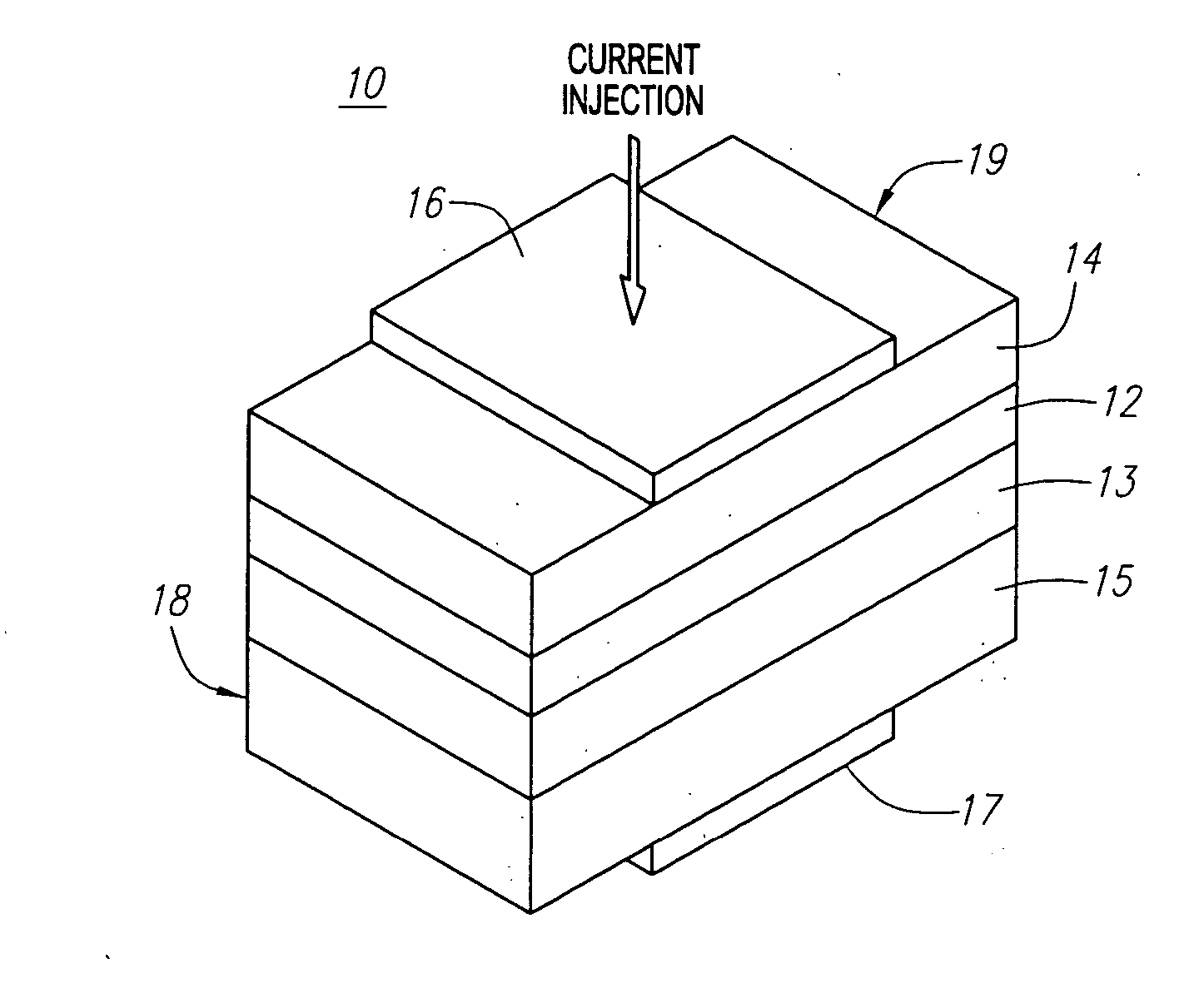

Turning to FIG. 1, a multi-layer semiconductor wafer structure of a laser diode 10 of the present invention is shown. The laser diode 10 preferably comprises an active or guiding layer 12 sandwiched between two cladding layers 13 and 14 on a substrate 15. The active layer (guiding) 12 is preferably non-doped or insulated and has a higher refractive index (n) and a smaller bandgap than the two cladding layers 13 and 14. The two cladding layers 13 and 14 are preferably highly doped with either n-type or p-type doping in order to reduce contact resistance. The substrate 15 is preferably more highl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com