III-V group nitride system semiconductor self-standing substrate, method of making the same and III-V group nitride system semiconductor wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

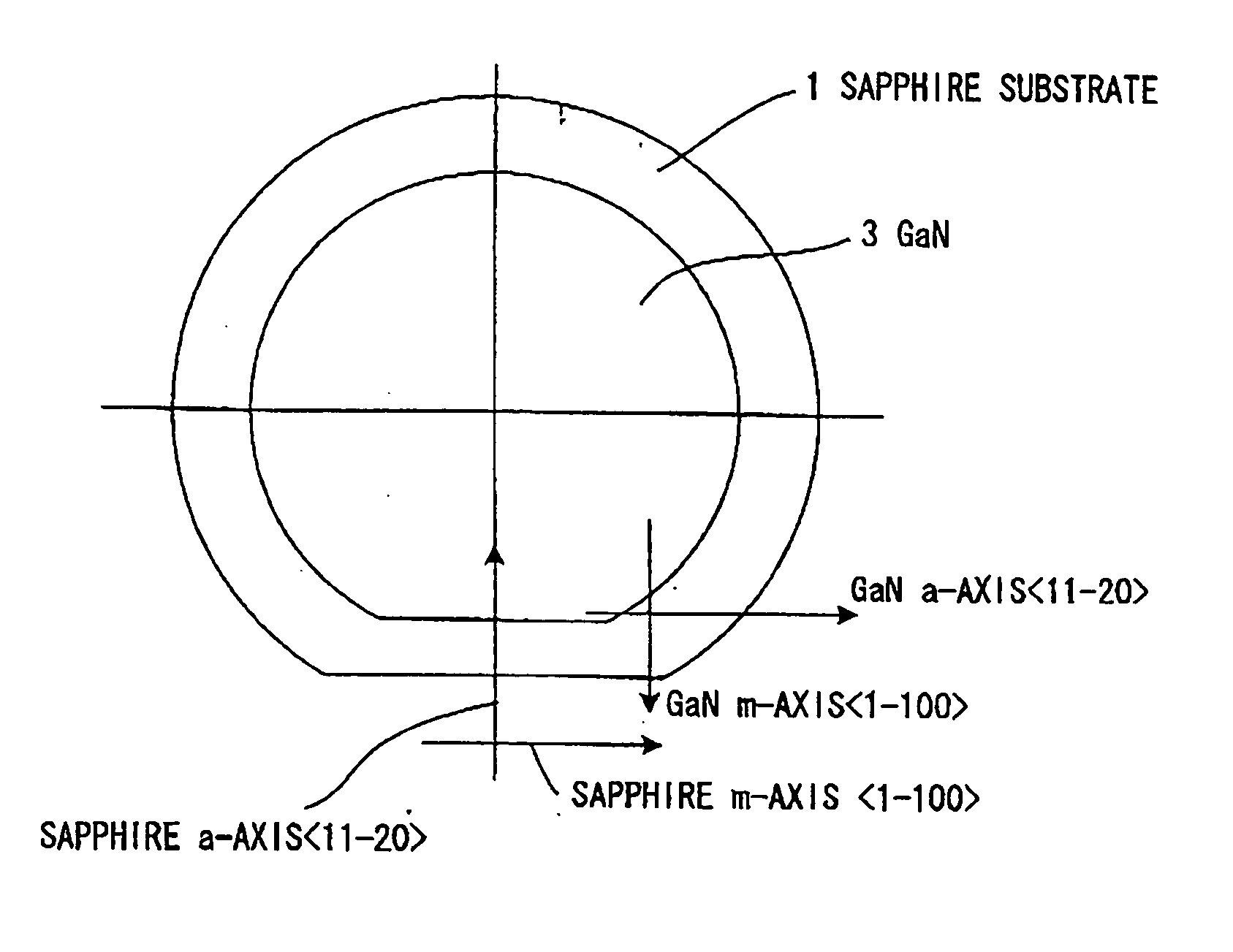

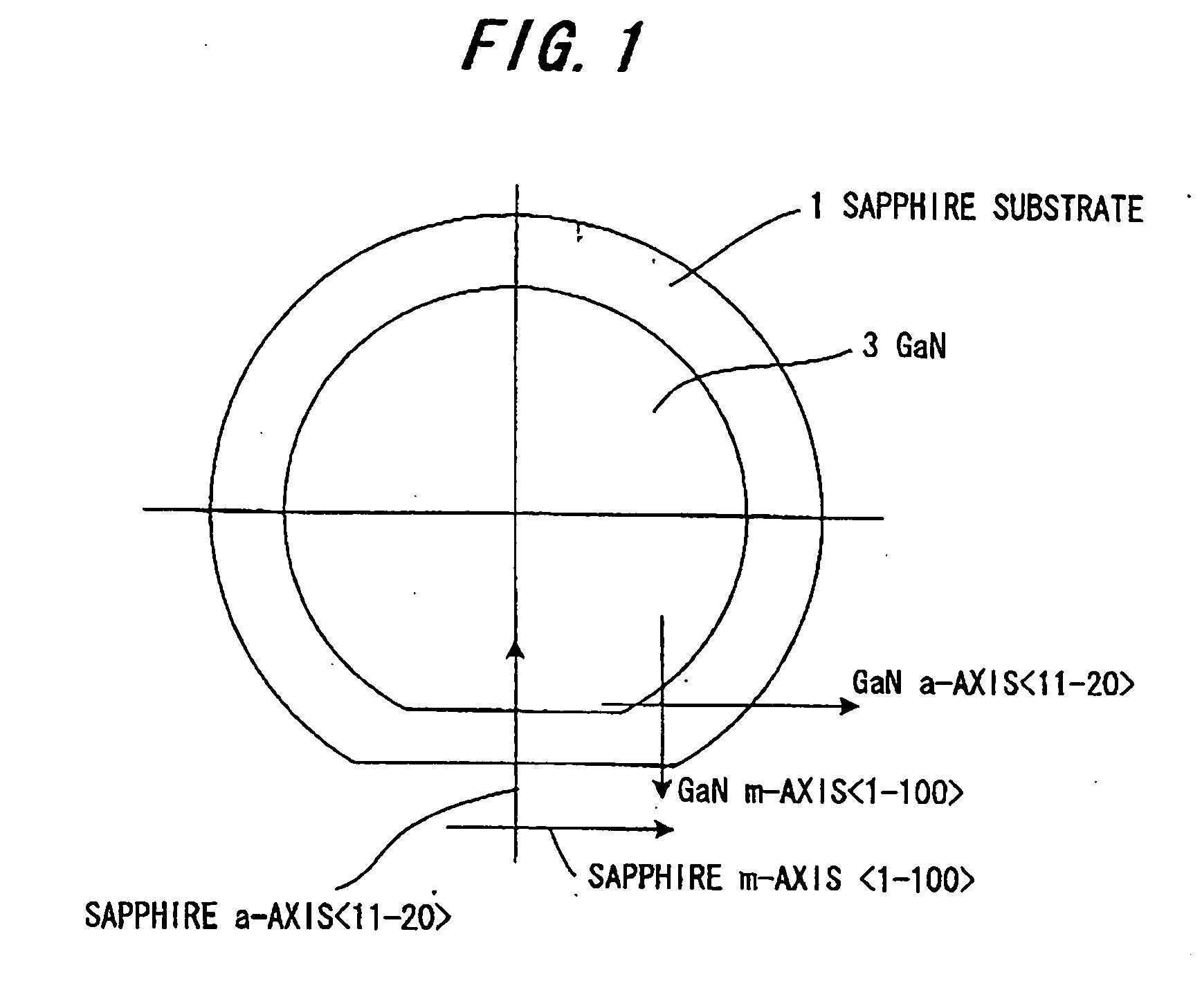

Image

Examples

example 1

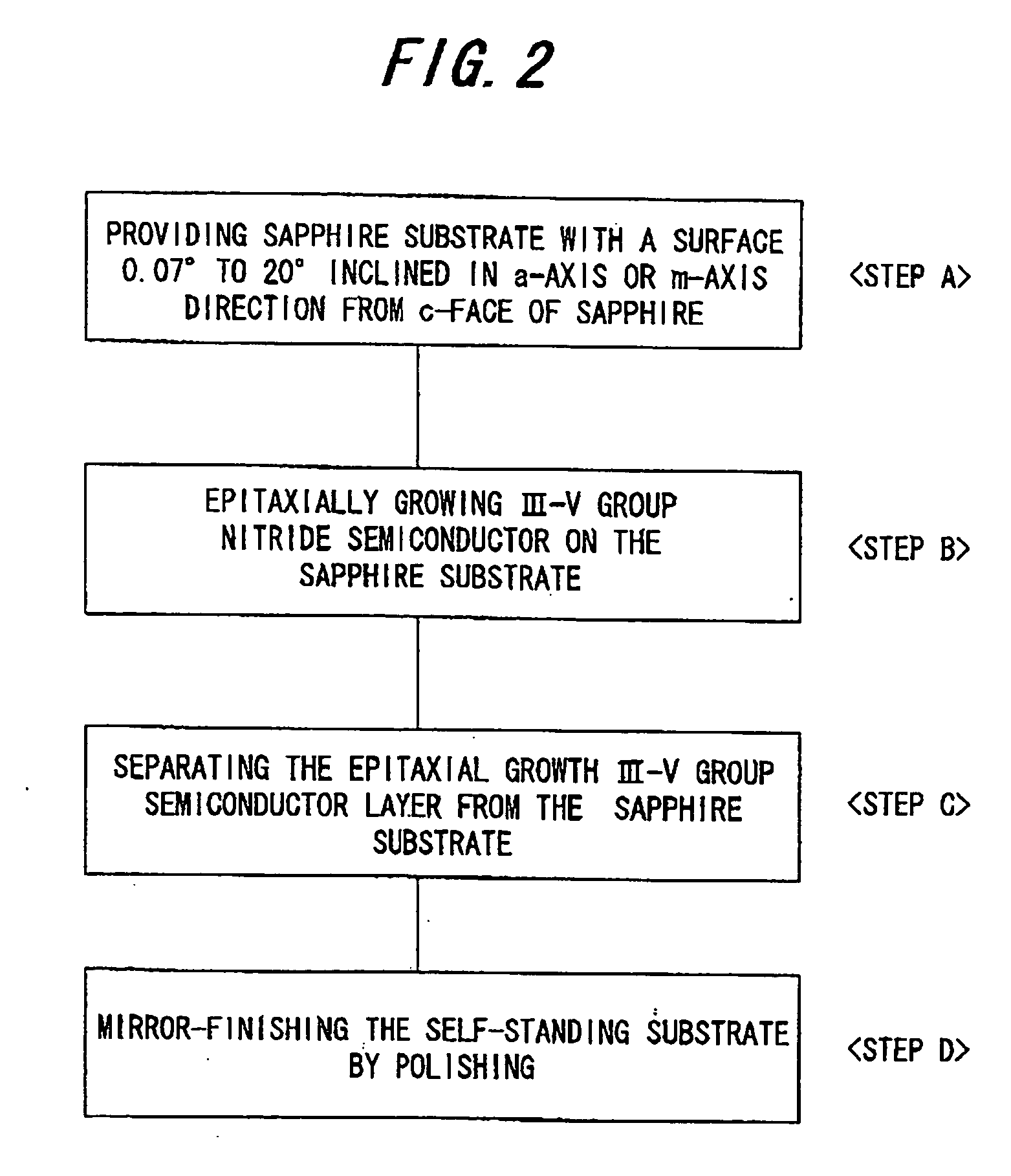

[0068] Manufacture of GaN Self-Standing Substrate

[0069] A GaN self-standing substrate is manufactured by a process as shown in FIG. 4. At first, single-crystal sapphire C-face substrates 21 with a diameter of 2 inches are provided that are each off-oriented 0.1, 0.5, 1, 3, 8, 15, 20 and 21 degrees in the m-axis direction (FIG. 4A).

[0070] Then, a 300 nm undoped GaN layer 22 is grown on the sapphire substrate 21 by MOVPE using TMG, NH3 as raw materials (FIG. 4B). Then, 20 nm Ti film 23 is deposited on the GaN epi-substrate (FIG. 4C), entered into an electric oven, and heated at 1050° C. for 20 min in H2 flow with 20% NH3 mixed therein. Thereby, Ti film 23 is processed into a mesh-like slotted TiN layer 25 and simultaneously the GaN layer 22 is processed into a void-formed GaN layer 24 (FIG. 4D).

[0071] This is entered in an HVPE furnace, and then a 500 μm GaN layer 26 is deposited (FIG. 4E). NH3 and GaCl are used raw materials and N2 is used as carrier gas. The growth conditions are...

example 2

[0075] Formation of GaN Layer on the GaN Self-Standing Substrate

[0076] The GaN self-standing substrates with different off-angles manufactured in Example 1 are mirror-finished by polishing on both surfaces. Then, as shown in FIG. 6, a 4 μm undoped layer 15 is grown on the GaN self-standing substrate 11 by MOVPE using TMG (trimethylgallium) and NH3 as raw materials. In the MOVPE growth, the growth pressure is atmospheric and the substrate temperature is 1050° C. The carrier gas is mixed gas of hydrogen and nitrogen. The crystal growth rate is about 4 μm / h.

[0077] The surface of epitaxial undoped GaN layer 15 thus obtained appears to be a mirror surface to the naked eye. However, when observing the surface by the Nomarski microscope, a number of microscopic hexagonal hillocks with a diameter of about 50 to 200 μm are generated on the surface of an epitaxial layer grown on substrates with an off-angle of less than 0.09 degrees. In contrast, on the surface of an epitaxial layer grown o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com