Porous film, composition and manufacturing method, interlayer dielectric film, and semiconductor device

a technology of dielectric film and porous film, which is applied in the direction of plastic/resin/waxes insulators, basic electric elements, coatings, etc., can solve the problems of increasing the cost affecting the performance of the first porous film forming method, and affecting the interconnection delay time, etc., to achieve the effect of reducing parasitic capacitance, reducing the amount of porous film forming method, and maintaining mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

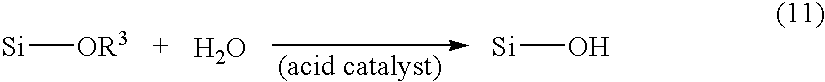

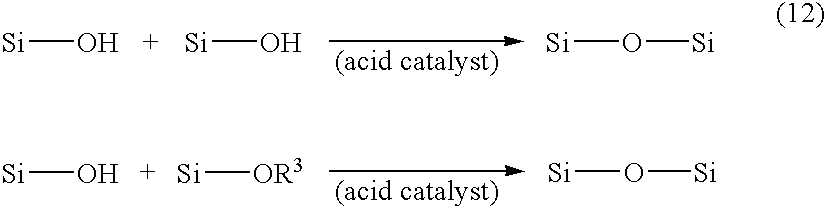

[0084] In a 50-ml flask, 15.22 g of tetramethoxysilane was hydrolyzed with 7.20 g of water (corresponding to twice the equivalent for hydrolysis) and 0.1 ml of 2N hydrochloric acid, yielding a silica precursor with Mw=1,450.

preparation example 2

[0085] In a 50-ml flask, a mixture of 11.42 g of tetramethoxysilane and 3.41 g of methyltrimethoxysilane was hydrolyzed with 6.75 g of water (corresponding to twice the equivalent for hydrolysis) and 0.1 ml of 2N hydrochloric acid, yielding a silica precursor with Mw=2,250.

preparation examples 3-7

[0086] Various surfactants, shown in Table 1, were added to the silica precursor solutions of Preparation Examples 1 and 2, which were diluted with water to form solutions having a solids (NV) concentration of 20%.

[0087] Note that Preparation Example is abbreviated as PE.

TABLE 1ResinC18H37NMe3ClC16H33NMe3OHC16H33NMe3OAcC12H25O(EO)9HWaterPreparationPreparation3.4 g14.8 gExample 3Example 1PreparationPreparation3.0 g14.8 gExample 4Example 1PreparationPreparation3.3 g14.8 gExample 5Example 1PreparationPreparation2.9 g14.8 gExample 6Example 1PreparationPreparation3.4 g14.8 gExample 7Example 2

Note:

Me = methyl,

Ac = acyl,

PUM

| Property | Measurement | Unit |

|---|---|---|

| mol % | aaaaa | aaaaa |

| pyrolytic temperature | aaaaa | aaaaa |

| relative dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com